Circulating water system optimization method based on permanent magnet adjustment and mechanical ventilation

A technology of circulating water system and mechanical ventilation, applied in the direction of design optimization/simulation, computer-aided design, instruments, etc., can solve the problems of poor optimization effect and single consideration factors, and achieve the effect of economical operation mode and good optimization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

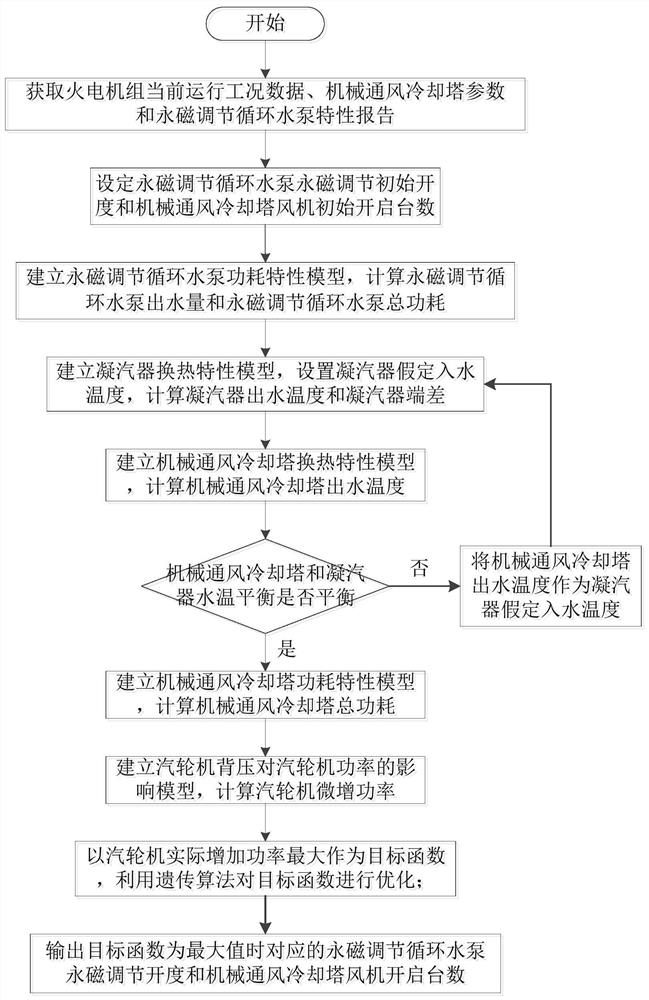

[0088] This embodiment provides a method for optimizing the circulating water system based on permanent magnet adjustment and mechanical ventilation, such as figure 1 As shown, the method includes the following steps:

[0089] A kind of circulating water system optimization method based on permanent magnet regulation and mechanical ventilation, it is characterized in that, described method comprises the following steps:

[0090] S1: Obtain the current operating condition data of the thermal power unit, the parameters of the mechanical ventilation cooling tower and the characteristic report of the permanent magnet regulating circulating water pump;

[0091] S2: Set the initial opening degree of the permanent magnet adjustment circulating water pump permanent magnet adjustment and the initial opening number of mechanical ventilation cooling tower fans;

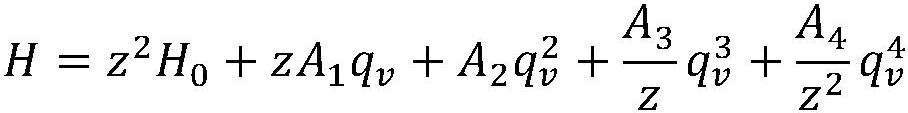

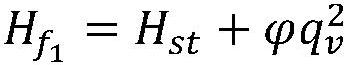

[0092] S3: Establish the power consumption characteristic model of the permanent magnet regulating circulating water pump, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com