High-performance silicon-carbon negative electrode material and preparation method thereof

A negative electrode material and high-performance technology, applied in the field of high-performance silicon carbon negative electrode material and its preparation, can solve the problems of low specific capacity of graphite negative electrode, poor conductivity due to volume change, hindering large-scale use, etc. The effect of capacity, good lithium ion intercalation and deintercalation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

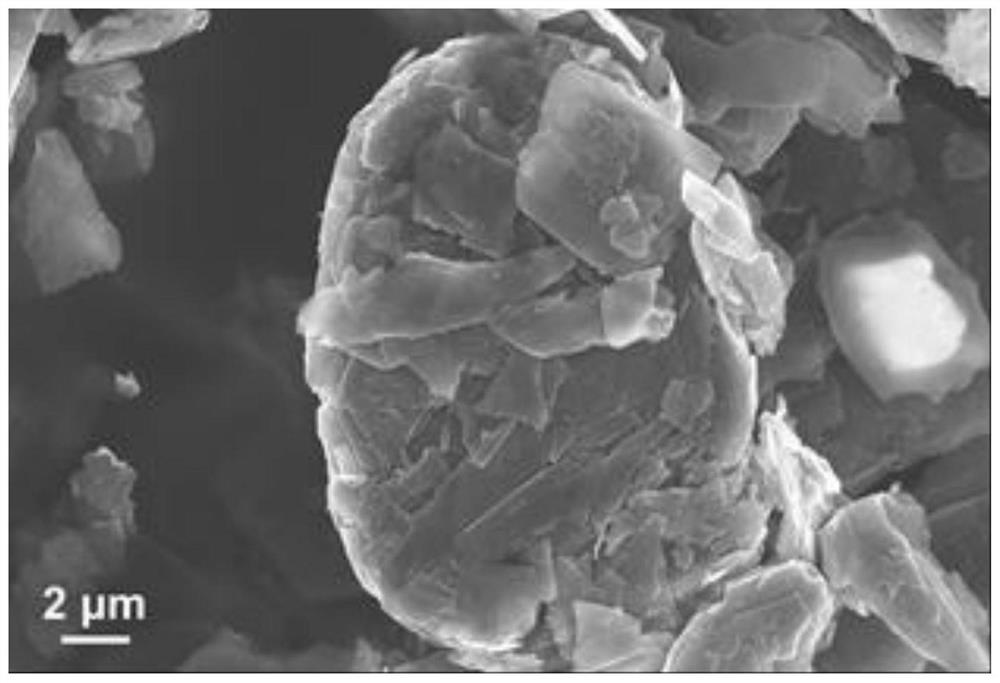

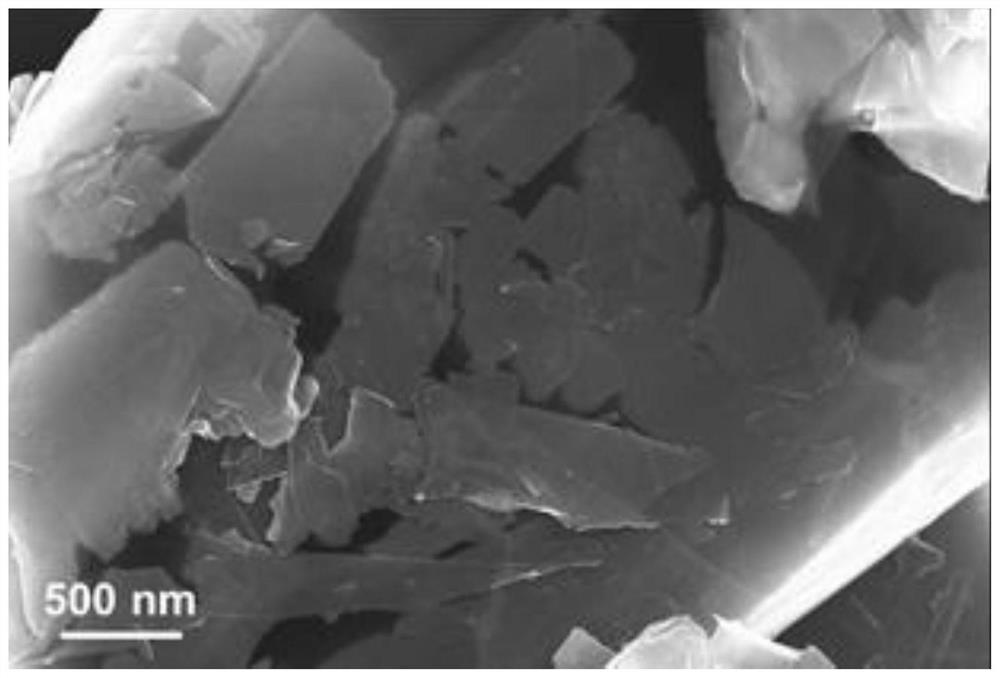

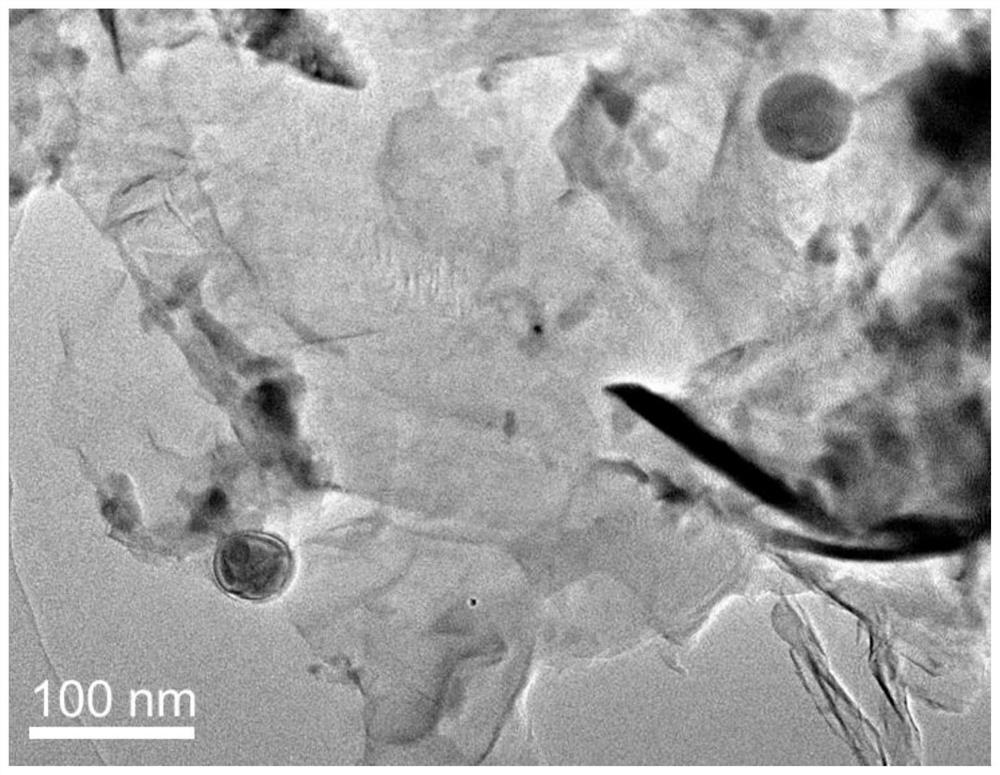

Image

Examples

Embodiment 1

[0029] Preparation of silicon carbon negative electrode materials:

[0030] 1) 1 g of spherical graphite is placed in a 7 mol / L of potassium hydroxide solution, stirred for 8 h; after drying at 80 ° C, the mixture is mixed at a temperature of 2 h at a nitrogen atmosphere of 800 ° C, washed with water and dry at 80 ° C to obtain etching graphite materials. ;

[0031] 2) The etchaven graphite was mixed in a 30 ml of ethanol solution, and 1.5 ml of ammonia was continuously stirred, then 2 g of orthosilicate was added and stirred for 3 h, after film finishing, dried, sollable gel product;

[0032] 3) Add a sol gel product and 10 g sodium chloride to 15 ml of deionized water, stirred and evaporated, mixed with 5 g of aluminum powder, heated at 700 ° C in argon, after 2 mol / L hydrochloride was washed filtrate, 80 ° C Drying, aluminum thermally reactive product;

[0033] 4) In the ethanol solution of the aluminum thermal reaction product, the graphite and the phenolic resin is 1: 0.5...

Embodiment 2

[0037] Preparation of a silicone carbon aperture material: Step 1) In the 4 mol / L of potassium hydroxide solution in step 1, 1 g of spherical graphite is used; other as in Example 1.

[0038] Assembly battery: in Example 1. Test electrochemical properties, the results are shown in Table 1.

Embodiment 3

[0040] Preparation of a silicone carbon aperture material: Step 1) In the 10 mol / L of potassium hydroxide solution in step 1);

[0041] Assembly battery: in Example 1. Test electrochemical properties, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com