Processing method of spicy preserved egg stuffing

A processing method and technology of preserved eggs, which are applied in metal processing, food science, etc., can solve problems such as different tastes, difficulty in cutting, and odors, and achieve the effects of increasing the audience, ensuring integrity, and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

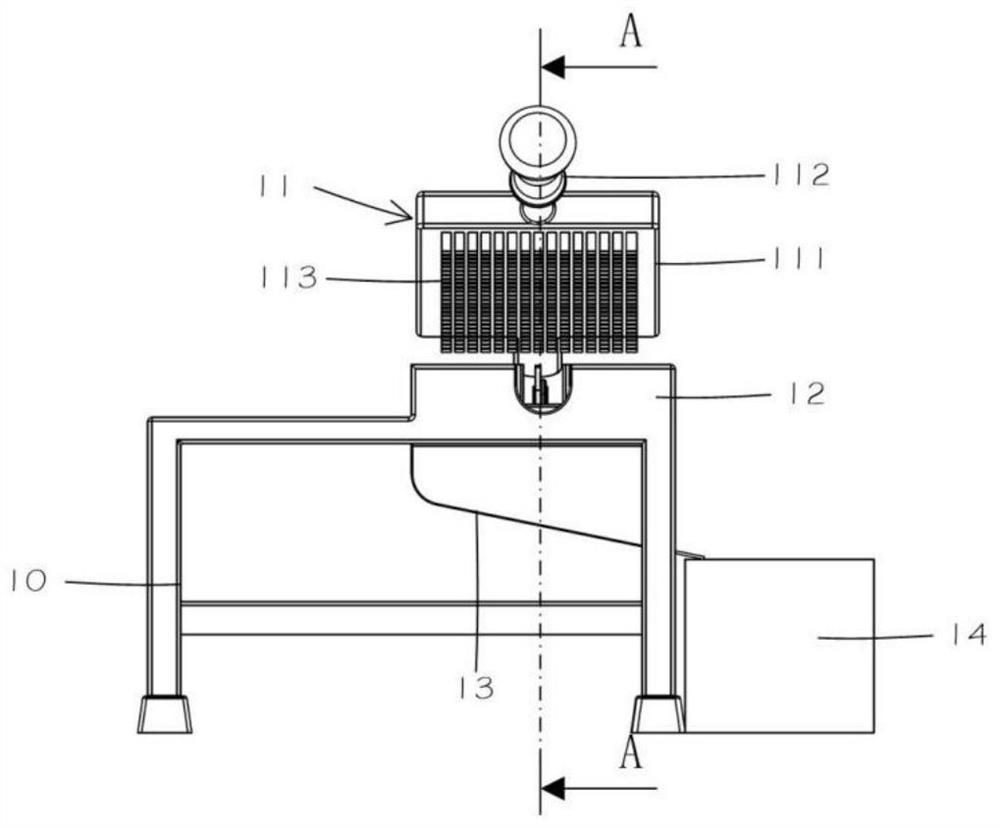

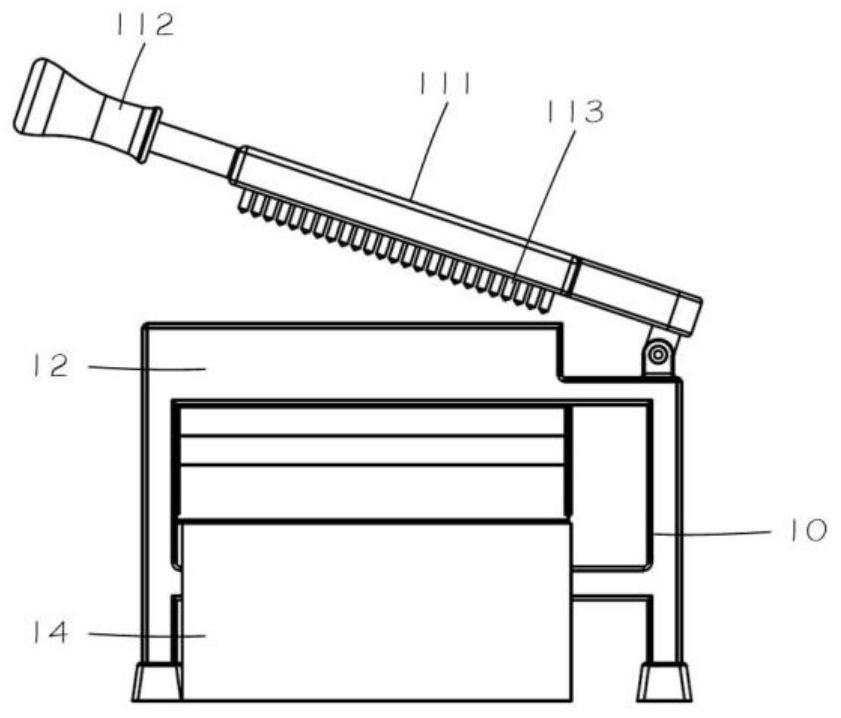

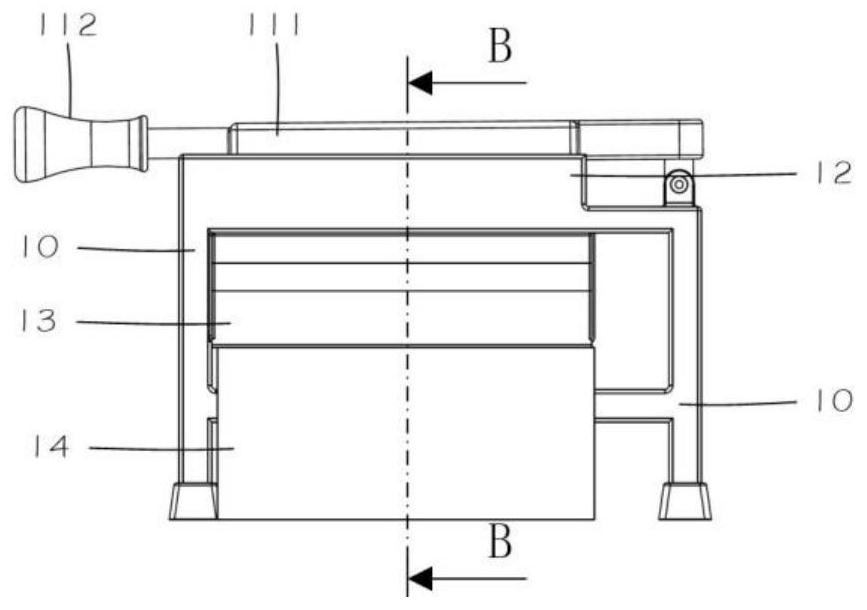

[0028] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0029] A spicy preserved egg filling, comprising the following raw materials in parts by weight: 200 parts of preserved eggs, 50 parts of pork, 10 parts of ginger, 10 parts of green onions, 10 parts of pepper powder, 20 parts of dried peppers, 20 parts of dried peppercorns, 5 parts of sesame oil, and 5 parts of cooking wine 5 servings of vinegar sauce.

[0030] A processing method for spicy preserved egg stuffing, comprising the following steps:

[0031] S1, weighing various ingredients according to the weight ratio of the ingredients;

[0032] S2, wash the pork, put them into the pulverizer respectively for pulverization, the speed of the pulverization blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com