A kind of high-permeability solid smoke bomb and preparation method thereof

A gas-permeable, solid smoke technology, applied in tobacco, tobacco processing, application, etc., can solve problems such as poor heating uniformity, complex pod processing technology, large air resistance, etc., to achieve low consumption and high efficiency in the production process, and the preparation process Simple, the effect of improving coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

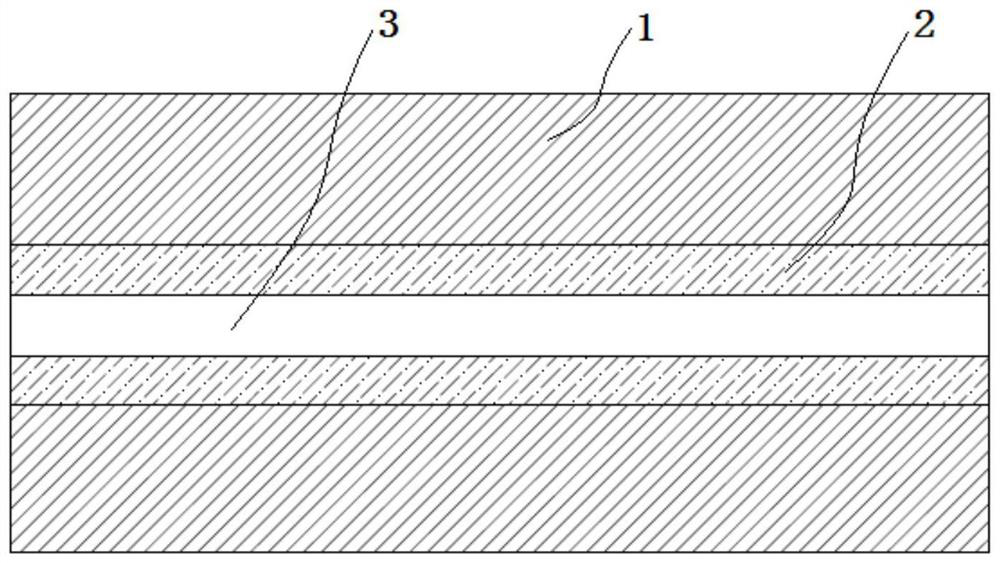

Image

Examples

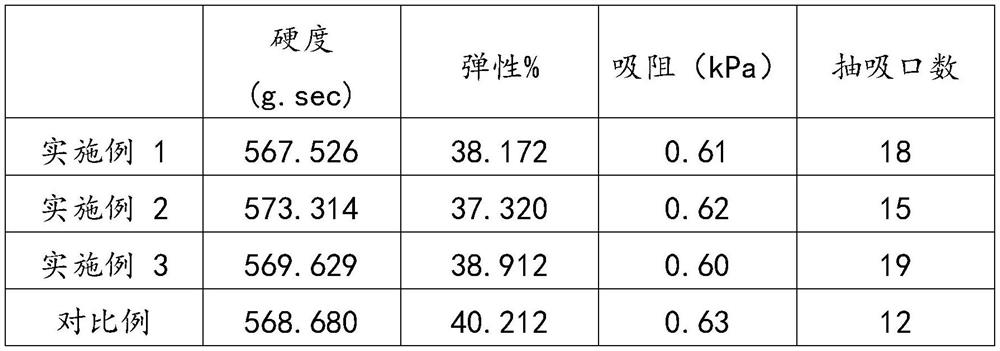

Embodiment 1

[0048] A preparation method of a high-permeability solid cartridge is as follows:

[0049] 1) Prepare the main material of the high-permeability solid pod:

[0050] The 20-mesh tobacco particles and the 60-mesh tobacco particles that have been dried at 35° C. for 2 minutes in a vacuum drying oven are mixed uniformly in a ratio of 6:4 by mass to obtain the first material.

[0051] 2) Preparation of high-permeability solid cartridge accessories:

[0052] Preparation of smoking agent: use glycerol and water to make a smoking agent in a ratio of 7:3 by mass;

[0053] Preparation of the first binder: the high acyl gellan gum and the low acyl gellan gum are made into a first mixed glue in a mass ratio of 6:4.

[0054] Preparation of the second binder: the high acyl gellan gum and the low acyl gellan gum are made into a second mixed glue in a ratio of 4:6 by mass.

[0055] The smoking agent and the first mixed glue are mixed in a mass ratio of 94:6, fully stirred and then allowed ...

Embodiment 2

[0063] A preparation method of a heat-not-burn solid cartridge is as follows:

[0064] 1) Prepare the main material of the high-permeability solid pod:

[0065] Mix the 20-mesh tobacco powder and 20-mesh microwave-expanded stem powder in a vacuum drying oven at 55°C for 1 min respectively in a ratio of 8:2 by mass to obtain a mixture, and then add a mixture with a mass ratio of 5%. Tobacco straw biomass charcoal is the first material.

[0066] 2) Preparation of high-permeability solid cartridge accessories:

[0067] Preparation of smoking agent: use glycerin and water to make a smoking agent in a ratio of 6:4 by mass;

[0068] For the preparation of the first binder, the high acyl gellan gum and the low acyl gellan gum are made into a first mixed glue in a mass ratio of 7:3.

[0069] Preparation of the second binder: the high acyl gellan gum and the low acyl gellan gum are made into a second mixed glue in a ratio of 5:5 by mass.

[0070] Mix the fuming agent and the first ...

Embodiment 3

[0078] A preparation method of a high-permeability solid cartridge is as follows:

[0079] 1) Prepare the main material of the high-permeability solid pod:

[0080] The 30-mesh tobacco powder and the 50-mesh tobacco powder are mixed uniformly in a ratio of 7:3 by mass in a vacuum drying oven at 45° C. and dried for 2 minutes to obtain the first material.

[0081] 2) Preparation of high-permeability solid cartridge accessories:

[0082] Preparation of smoking agent: using glycerin and water according to the mass ratio of 5:5 to prepare the smoking agent.

[0083] Preparation of the first binder: the high acyl gellan gum and the low acyl gellan gum are made into a first mixed glue in a ratio of 5:5 by mass.

[0084] Preparation of the second binder: the high acyl gellan gum and the low acyl gellan gum are made into a second mixed glue in a ratio of 3:7 by mass.

[0085] Mix the fuming agent and the first mixed glue according to the mass ratio of 98:2, fully stir and then let ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com