Ferrosilicon nitride mullite silicon carbide brick for silicomanganese alloy ladle and preparation method of ferrosilicon nitride mullite silicon carbide brick

A mullite silicon carbide brick and ferrosilicon nitride technology, which is applied in metal processing equipment, manufacturing tools, casting equipment, etc., can solve the problems of slag erosion resistance, melt erosion resistance and thermal shock resistance. , Restricting the efficient and stable production of silicon-manganese alloys, frequent maintenance of alloy packages, etc., to achieve excellent resistance to slag erosion, ensure the quality of preparation, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

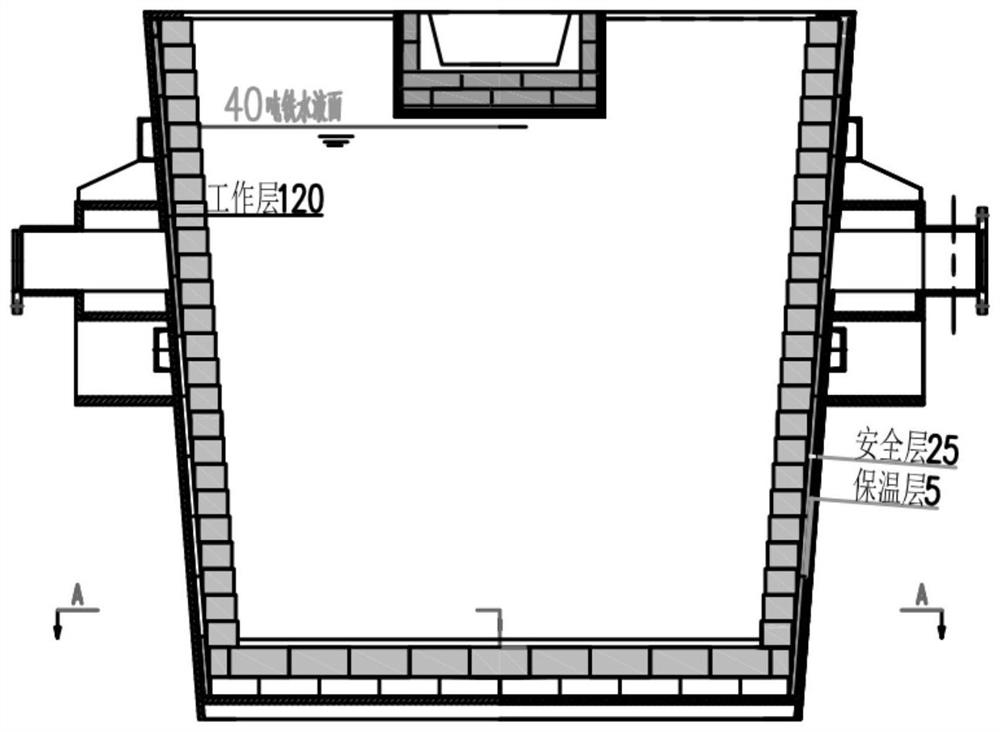

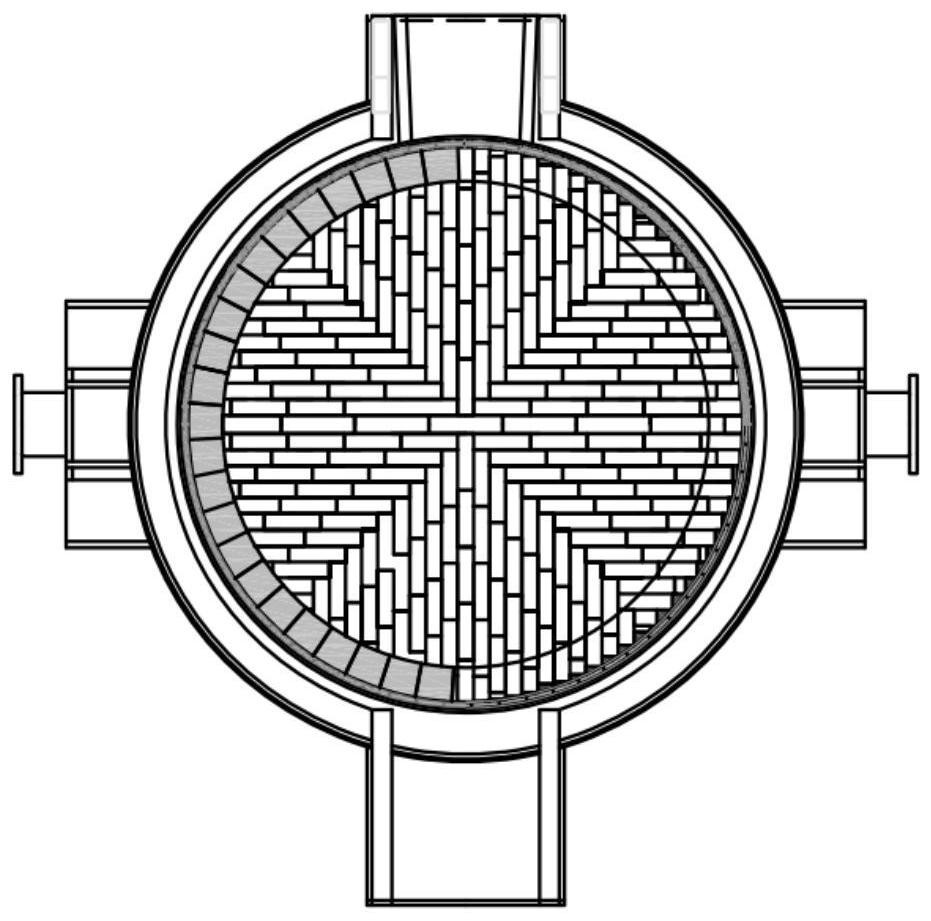

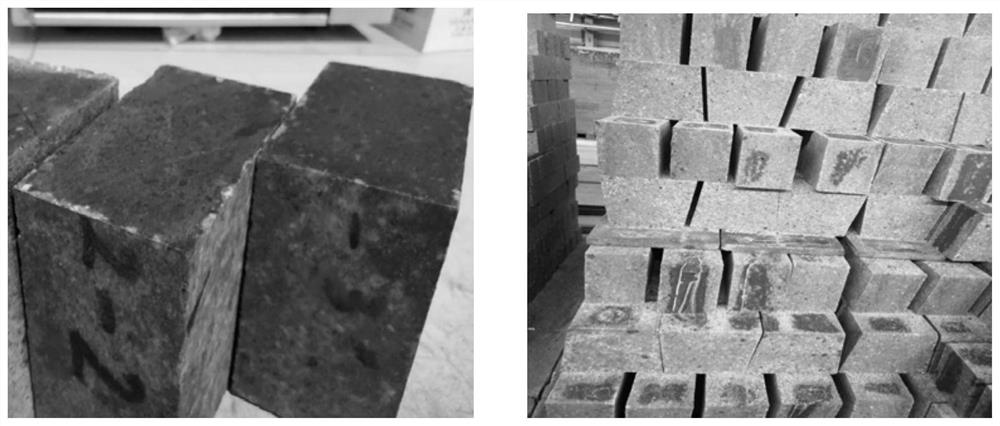

Image

Examples

Embodiment 1

[0035] A Si-Mn alloy-coated ferrosilicon nitride-mullite silicon carbide brick, comprising the following raw materials in mass percentage:

[0036]

[0037] The moisture mass content of silicon carbide and ferrosilicon nitride fine powder in the raw materials is all ≤0.3%, and the moisture mass content of other raw materials is all ≤0.5%.

[0038] The preparation method of the silicon-manganese alloy-coated ferrosilicon nitride-mullite silicon carbide brick comprises the following steps:

[0039] Add the prepared granules into the mixer and stir for 2 minutes, then add the weighed binding solution, mix for 3 minutes, then add the weighed fine powder, mix for 5 minutes, and discharge after mixing evenly. Mix and stir for no less than 12 minutes; use a double-screw program-controlled 630T press for molding, use the first blow at a speed of 180 rpm, and then exhaust once, and then increase the speed at each gear to 50 rpm, and press to five gears; After drying, the temperatur...

Embodiment 2

[0041] A Si-Mn alloy-coated ferrosilicon nitride-mullite silicon carbide brick, comprising the following raw materials in mass percentage:

[0042]

[0043] The moisture mass content of silicon carbide and ferrosilicon nitride in the raw materials are all ≤0.3%, and the moisture content of other raw materials are all ≤0.5%.

[0044] The preparation method of the silicon-manganese alloy-coated ferrosilicon nitride-mullite silicon carbide brick comprises the following steps:

[0045] Put the prepared granules into the mixer and stir for 2 minutes, then add the weighed binding solution, mix for 5 minutes, then add the weighed fine powder, mix for 8 minutes, and discharge after mixing evenly. Mix and stir for no less than 12 minutes; use a double-screw program-controlled 630T press for molding, use the first blow at a speed of 180 rpm, and then exhaust once, and then increase the speed at each gear to 50 rpm, and press to five gears; After drying, the temperature is raised at ...

Embodiment 3

[0047] A Si-Mn alloy-coated ferrosilicon nitride-mullite silicon carbide brick, comprising the following raw materials in mass percentage:

[0048]

[0049]

[0050] The moisture mass content of silicon carbide and ferrosilicon nitride in the raw materials are all ≤0.3%, and the moisture content of other raw materials are all ≤0.5%.

[0051] The preparation method of the silicon-manganese alloy-coated ferrosilicon nitride-mullite silicon carbide brick comprises the following steps:

[0052] Add the prepared granules into the mixer and stir for 2 minutes, then add the weighed binding solution, mix for 4 minutes, then add the weighed fine powder, mix for 6 minutes, and discharge after mixing evenly. Mix and stir for no less than 12 minutes; use a double-screw program-controlled 630T press for molding, use the first blow at a speed of 180 rpm, and then exhaust once, and then increase the speed at each gear to 50 rpm, and press to five gears; After drying, the temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com