Metallurgic slag oxygen ion conductivity cell

A conductivity cell, oxygen ion technology, applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

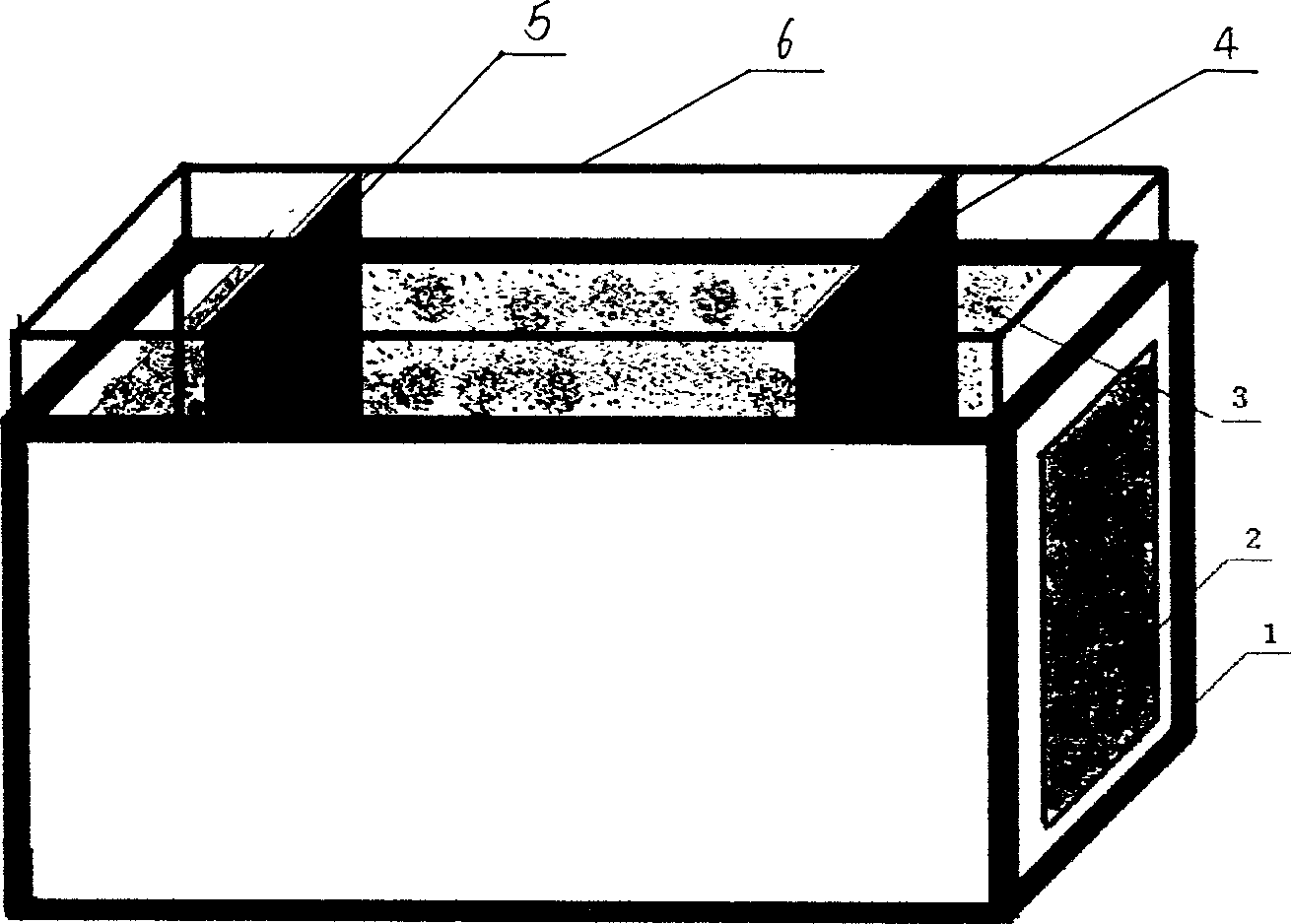

[0007] In the present invention, porous platinum electrodes 2 are respectively installed on both sides of the conductance cell 1 to form the positive and negative poles of the battery. The conductance cell 1 is equipped with molten slag 3, and platinum sheets 4 and 5 are inserted into the molten slag 3 as electrodes for measuring voltage. , above the conductivity cell 1 is provided with a fixed platinum sheet electrode fixing device 6 .

[0008] The two electrodes 2 of porous platinum are symmetrical.

[0009] The fixing device 5 is a ceramic clamp to fix the platinum sheet.

[0010] Use Y 2 o 3 Stabilized ZrO 2 Ultrafine powder is used as raw material, formed by gypsum injection method, fired at 1500°C with length, width and height of 30-50mm, 10-30mm, 10-30mm respectively, and a conductivity cell with a wall thickness of 1-3mm. The platinum acid decomposition method is used to make porous platinum electrodes on the left and right sides, with an area of (10-20)mm×(10-20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com