Device and method for precise measurement of theoretical point of low pressure rotor profile

A low-pressure rotor, precision measurement technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical diameter measurement, etc., can solve the problems of low efficiency, increased quality risk, inconvenient measurement, etc., to achieve convenient use, reduced quality cost, weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

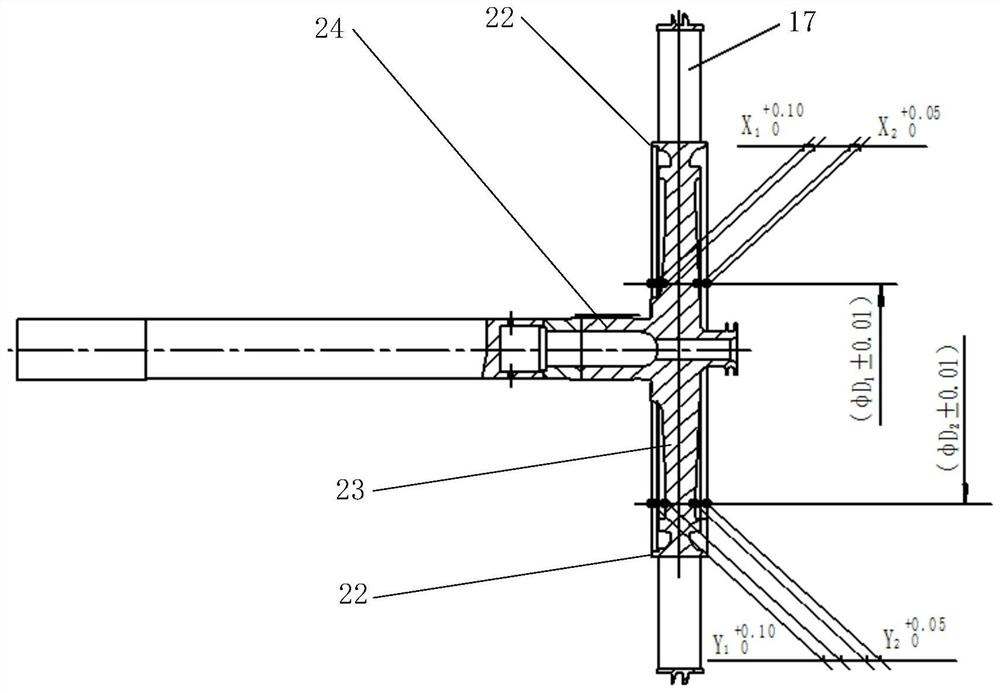

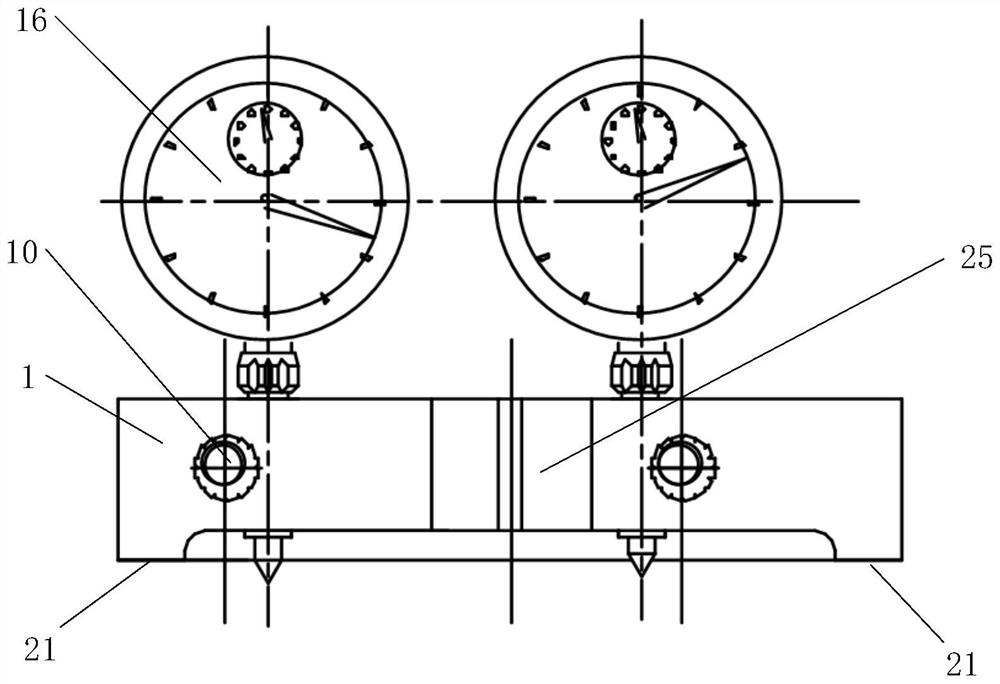

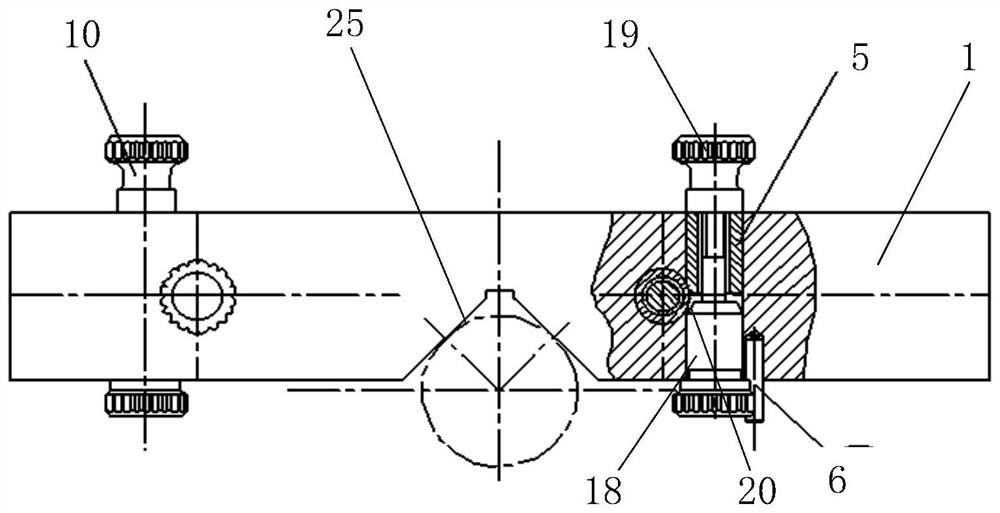

[0046] This embodiment takes the measurement of the theoretical point of the low-pressure rotor 17 profile of a small engine as an example to describe the precision measurement device and method for the theoretical point of the low-pressure rotor 17 profile, as figure 1 As shown, the end face 22 (i.e. the reference plane) of the low-pressure rotor 17 is a plane perpendicular to the axis, and the profile to be processed and measured is a tapered surface. The balance accuracy of the rotor 17, the engine assembly quality, performance, reliability and other important indicators, so the accuracy of the theoretical point size of the low-pressure rotor 17 profile is the key to ensuring the quality of this part.

[0047] Such as figure 1 As shown, the low-pressure rotor 17 is composed of a disk 23 (diameter ≥ 460mm) and a shaft 24 (part length ≥ 440mm), the disk 23 is composed of a hub and blades, and the two ends of the hub 22 are processed with profiles. The theoretical point is tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com