Preparation method of solid smoke cartridge

A technology for solid cigarettes and pods, which is applied in the fields of tobacco, tobacco processing, and application, can solve the problems of insufficient smoke concentration, complex processing technology, large gaps, etc., and achieves low consumption and high efficiency in the production process, simple preparation process, and improved ventilation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

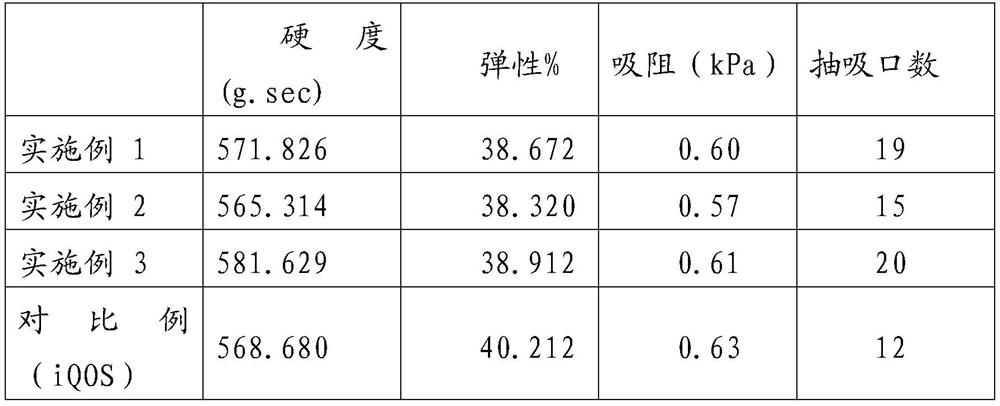

Examples

preparation example Construction

[0030] The preparation method of the composite particle of the present application comprises the following steps:

[0031] 1) preparing tobacco stalks into tobacco stalk biochar;

[0032] 2) Pulverizing the tobacco straw biochar into biochar particles with a set diameter range.

[0033] 3) Dilute the attachment used for immersion in the tobacco straw biochar by 50 times to obtain an attachment solution, immerse the biochar particles in step 2) in the attachment solution for 2 hours, filter, and dry to obtain composite particles billet.

[0034] 4) Spray 0.1% of the Peruvian extract by weight of the composite particle blank and 0.5% of the fixative by weight of the composite particle blank onto the composite particle blank.

[0035] 5) Using a disc granulator to pulverize the composite granule blank in step 4) and then sieve to obtain tobacco stalk biochar composite granules.

Embodiment 1

[0037] A method for preparing a solid cartridge, comprising the following steps:

[0038] 1) Preparation of heat-not-burn solid pod main material:

[0039] The pre-dried 20-mesh tobacco particles and 60-mesh tobacco particles are uniformly mixed in a mass ratio of 6:4 to obtain the first material.

[0040] 2) Mix the composite particles into the first material according to the ratio of 1% of the mass of the first material to obtain the second material. particles;

[0041] 3) Preparation of heat-not-burn solid pod accessories:

[0042] Glycerin and water are used to make a fuming agent according to the mass ratio of 7:3, and high acyl gellan gum and low acyl gellan gum are used to make a pectin adhesive in a mass ratio of 4:6, and the fuming agent Mix with the binder at a mass ratio of 90:10, stir well and let stand for 5 minutes to obtain the third material.

[0043] 4) Preparation of heat-not-burn solid pod material:

[0044] Mix the second material and the third materia...

Embodiment 2

[0048] A method for preparing a solid cartridge, comprising the following steps:

[0049] 1) Preparation of heat-not-burn solid pod main material:

[0050] The 20-mesh tobacco powder and the 20-mesh microwave expanded stem powder are uniformly mixed in a mass ratio of 8:2 to obtain the first material.

[0051] 2) According to the ratio of 5% of the mass of the first material, the composite particles are mixed into the first material to obtain the second material. particles;

[0052] 3) Preparation of heat-not-burn solid pod accessories:

[0053] Glycerin and water are used to make a fuming agent according to the ratio of mass ratio of 8:2, and high acyl gellan gum and low acyl gellan gum are used to make pectin adhesive according to the ratio of mass ratio of 6:4, and the fuming agent Mix with the binder at a mass ratio of 94:6, stir well and let stand for 5 minutes to obtain the third material.

[0054] 4) Preparation of heat-not-burn solid pod material:

[0055] Mix the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com