Solid cartridge suitable for heat-not-burn smoking set and preparation method

A heat-not-burn and solid-smoke technology, which is applied in the fields of application, tobacco, and tobacco treatment, can solve the problems of high waste pollution, insufficient smoke quality and quantity, and high cost, and achieve low-consumption and high-efficiency production processes, simple preparation processes, and multiple The effect of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

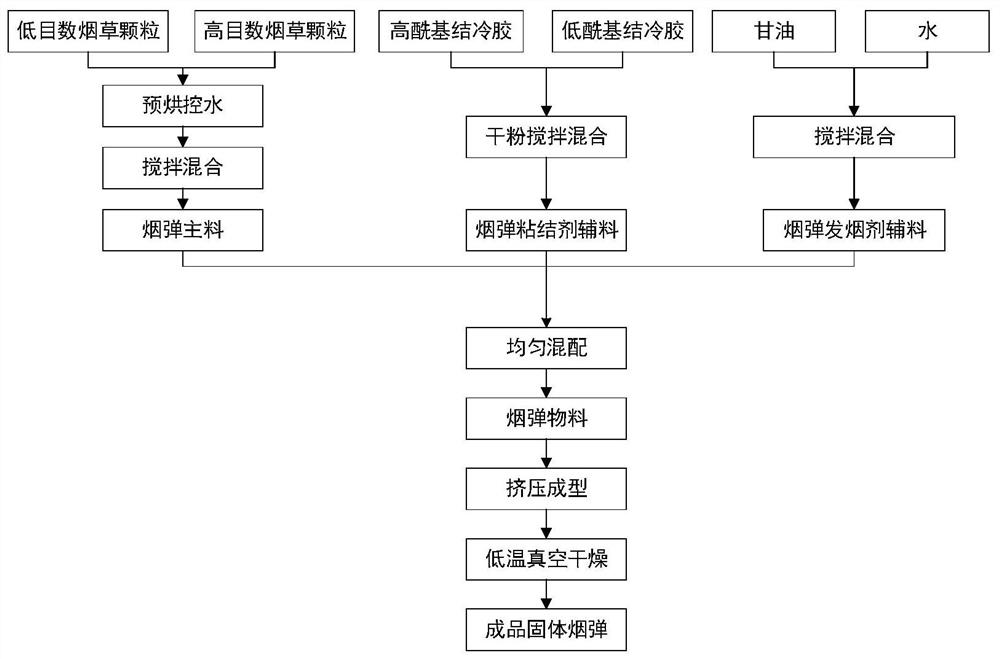

Image

Examples

Embodiment 1

[0034] 1) Prepare the main material of the heat not burn solid cartridge:

[0035] The 20-mesh tobacco particles and the 60-mesh tobacco particles are uniformly mixed in a ratio of 6:4 by mass to obtain the first material.

[0036] 2) Preparation of heat-not-burn solid cartridge accessories:

[0037] Use glycerin and water to make a fuming agent in a ratio of 8:2 by mass, and use high acyl gellan gum and low acyl gellan gum to make a pectin adhesive in a ratio of 6:4 by mass, and mix the fuming agent Mix it with the binder according to the mass ratio of 94:6, fully stir it and let it stand for 5 minutes to obtain the second material.

[0038] 3) Preparation of heat-not-burn solid pod material:

[0039] The first material and the second material are mixed evenly in a ratio of 6:4 by mass to obtain the third material.

[0040] 4) Preparation of heat-not-burn solid cartridges:

[0041] The third material is placed in a vacuum drying box and preheated at 40°C for 2 minutes, th...

Embodiment 2

[0043] 1) Prepare the main material of the heat not burn solid cartridge:

[0044] The 20-mesh tobacco powder and the 20-mesh microwave-expanded stem powder are uniformly mixed in a ratio of 6:4 by mass to obtain the first material.

[0045] 2) Preparation of heat-not-burn solid cartridge accessories:

[0046] Use glycerin and water to make a fuming agent in a ratio of 8:2 by mass, and use high acyl gellan gum and low acyl gellan gum to make a pectin adhesive in a ratio of 6:4 by mass, and mix the fuming agent Mix it with the binder according to the mass ratio of 94:6, fully stir it and let it stand for 5 minutes to obtain the second material.

[0047] 3) Preparation of heat-not-burn solid pod material:

[0048] The first material and the second material are mixed evenly in a ratio of 6:4 by mass to obtain the third material.

[0049] 4) Preparation of heat-not-burn solid cartridges:

[0050] The third material is placed in a vacuum drying box and preheated at 40°C for 2 m...

Embodiment 3

[0052] 1) Prepare the main material of the heat not burn solid cartridge:

[0053] Mix the 20-mesh tobacco powder and the 60-mesh tobacco powder in a ratio of 6:4 by mass, and use high-acyl gellan gum and low-acyl gellan gum in a mass ratio of 6:4 to make pectin adhesive. The first material is obtained by mixing the tobacco leaf raw material and the binder dry powder in a mass ratio of 94:6.

[0054] 2) Preparation of heat-not-burn solid cartridge accessories:

[0055] Using glycerin and water according to the mass ratio of 8:2 to prepare a smoke agent, fully stirring and then allowing to stand for 5 minutes to obtain the second material.

[0056] 3) Preparation of heat-not-burn solid pod material:

[0057] The first material and the second material are mixed evenly in a ratio of 6:4 by mass to obtain the third material.

[0058] 4) Preparation of heat-not-burn solid cartridges:

[0059] The third material is placed in a vacuum drying box and preheated at 40°C for 2 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com