A kind of in situ generation perovskite heterojunction photocatalyst and its preparation method

A photocatalyst and in-situ generation technology, applied in the field of photocatalysis, can solve the problems of poor stability and low photocatalytic activity, and achieve the effects of mild reaction, simple synthesis and enhanced activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

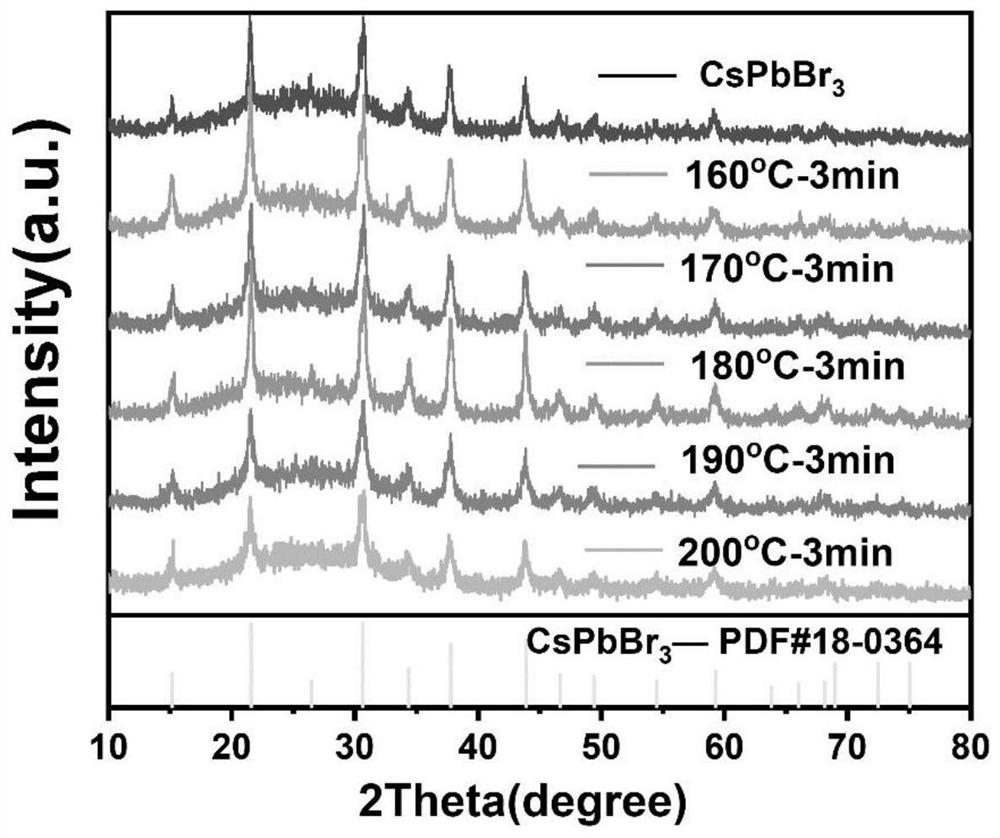

[0042] A pure phase CsPbBr 3 The preparation method of perovskite quantum dot photocatalyst comprises the following steps:

[0043] All reaction processes were carried out under the protection of argon. Add 27mg of cesium carbonate to 1.4ml of octadecene and 0.2ml of oleic acid mixed solvent, react at 120°C for 1h, fully dissolve the cesium carbonate, and generate a precursor solution containing Cs; in 15ml of octadecene, 1.5ml of oleylamine and Add 207 mg of lead bromide to 1.5 ml of oleic acid mixed solvent, and react at 150°C for 1 hour to fully dissolve lead bromide to generate a Pb-containing precursor solution; quickly inject the Cs-containing precursor solution into the Pb-containing precursor solution through a needle, React at a reaction temperature of 150°C for 5 seconds, quickly put it into the ice-water mixture, and quickly drop the temperature of the solution to 40°C to terminate the reaction of the Pb precursor solution and the Cs precursor solution; In the tub...

Embodiment 2

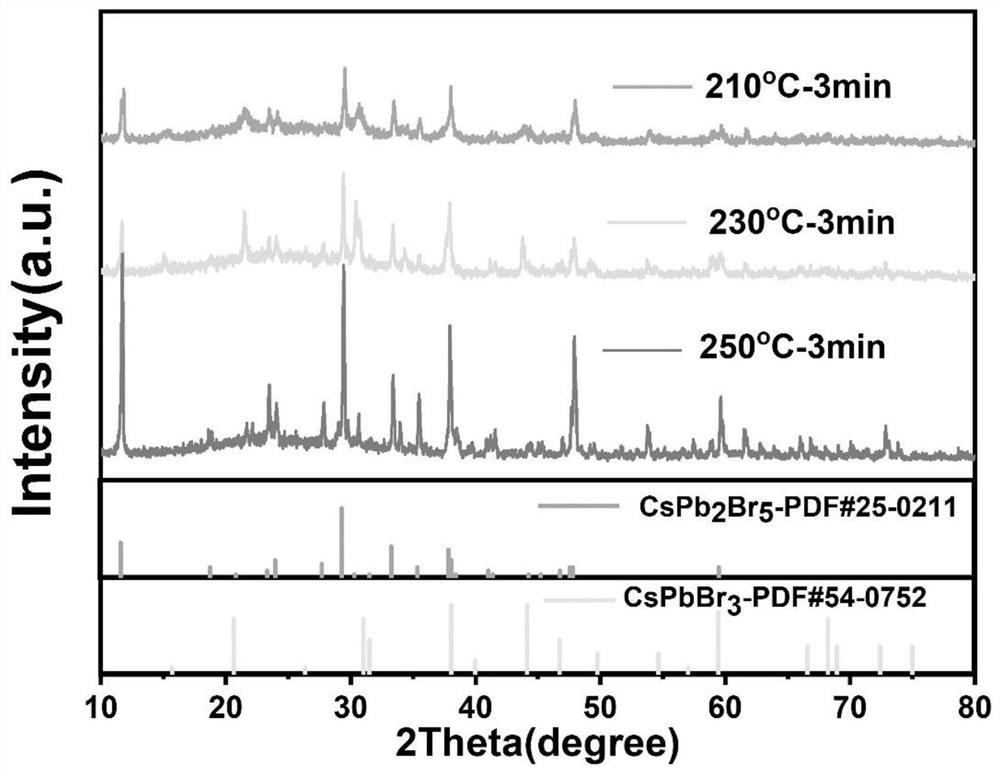

[0045] A preparation method for in-situ generation of perovskite heterojunction photocatalysts, comprising the following steps:

[0046] All reaction processes were carried out under the protection of argon. Add 27mg of cesium carbonate to 1.4ml of octadecene and 0.2ml of oleic acid mixed solvent, react at 120°C for 1h, fully dissolve the cesium carbonate, and generate a precursor solution containing Cs; in 15ml of octadecene, 1.5ml of oleylamine and Add 207 mg of lead bromide to 1.5 ml of oleic acid mixed solvent, and react at 150°C for 1 hour to fully dissolve lead bromide to generate a Pb-containing precursor solution; quickly inject the Cs-containing precursor solution into the Pb-containing precursor solution through a needle, React at a reaction temperature of 150°C for 5 seconds, quickly put it into an ice-water mixture, rapidly drop the temperature of the solution to 40°C, and terminate the reaction of the Pb-containing precursor solution and the Cs precursor solution;...

Embodiment 3

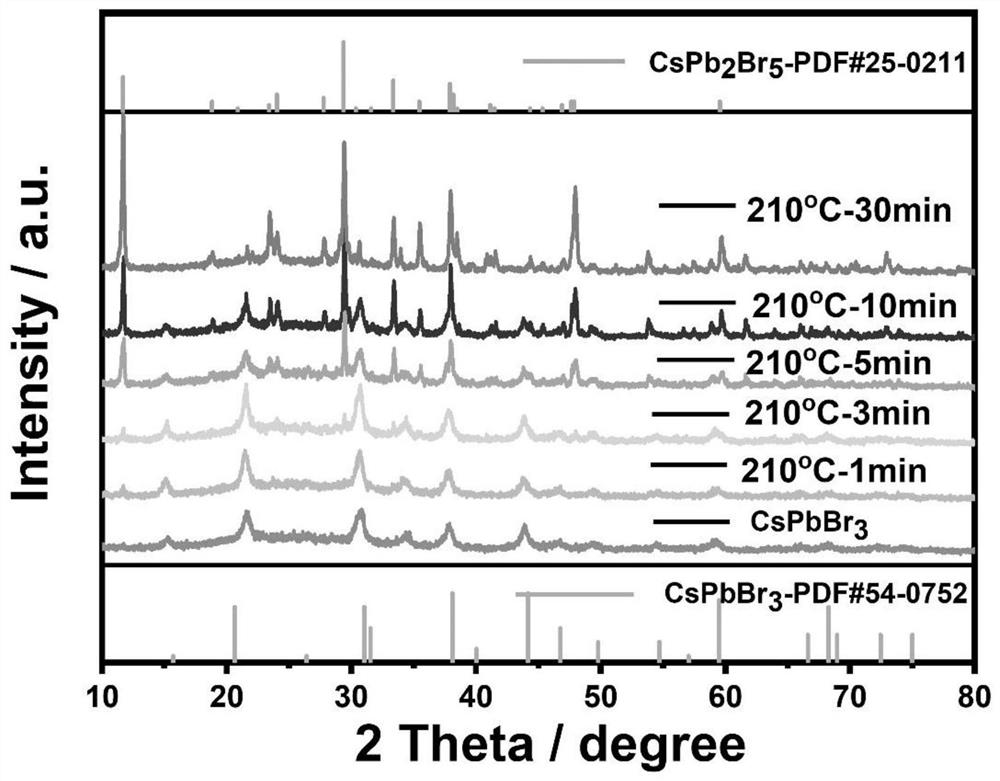

[0050] A preparation method for in-situ generation of perovskite heterojunction photocatalysts, comprising the following steps:

[0051] All reaction processes were carried out under the protection of argon. Add 27mg of cesium carbonate to 1.4ml of octadecene and 0.2ml of oleic acid mixed solvent, react at 120°C for 1h, fully dissolve the cesium carbonate, and generate a precursor solution containing Cs; in 15ml of octadecene, 1.5ml of oleylamine and Add 207 mg of lead bromide to 1.5 ml of oleic acid mixed solvent, and react at 150°C for 1 hour to fully dissolve lead bromide to generate a Pb-containing precursor solution; quickly inject the Cs-containing precursor solution into the Pb-containing precursor solution through a needle, React at a reaction temperature of 150°C for 5 seconds, quickly put it into an ice-water mixture, rapidly drop the temperature of the solution to 40°C, and terminate the reaction of the Pb-containing precursor solution and the Cs precursor solution;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com