Connecting and locking structure for roller shaft of overturning plate of grinding-in press machine

A technology of locking structure and flipping plate, applied in the direction of grinding machine parts, metal processing equipment, grinding machines, etc., can solve the problems of eccentric load tightening force, bearing damage, loose connection, etc., to achieve large locking force and reduce failures. Downtime, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

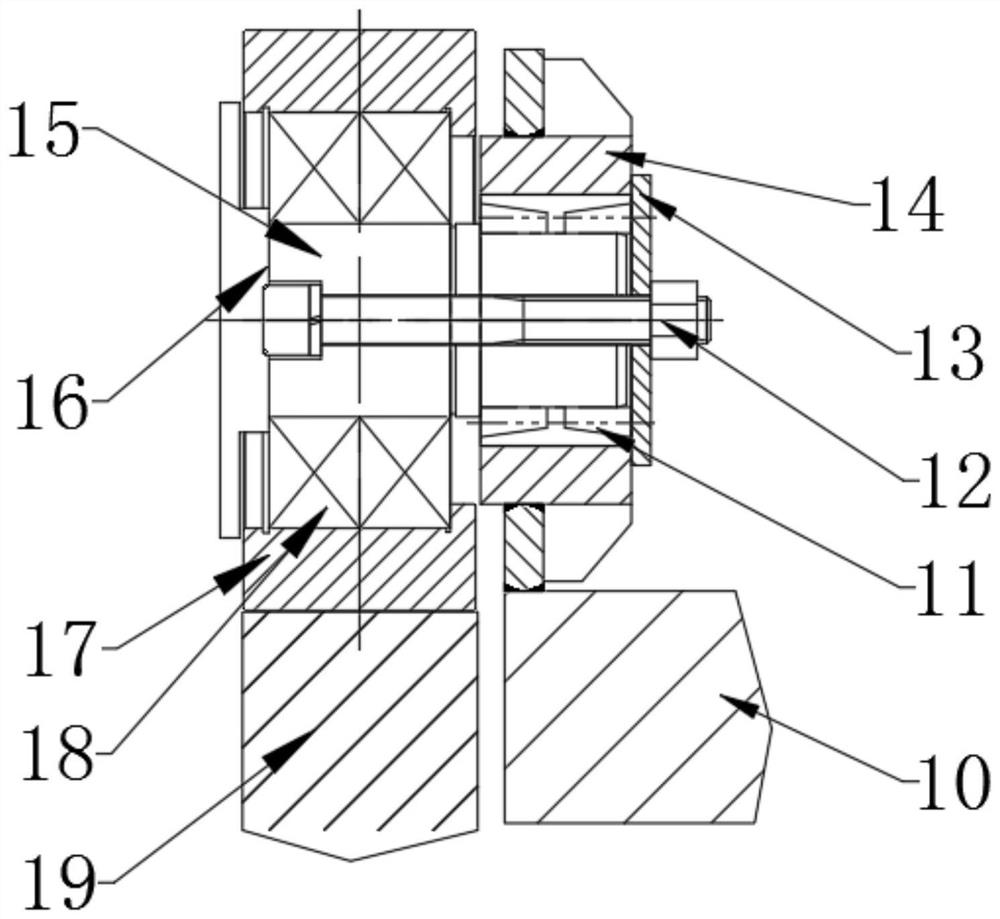

[0018] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix figure 2 , a further detailed description will be given on the connection and locking structure of the turning plate roller wheel shaft of the research and distribution press of the present invention.

[0019] refer to figure 2 As shown, in the research and distribution press of the present invention, the turning plate roller II shaft is connected to the locking structure. The guide rail II19 of the research and distribution press is provided with a roller II17, and the transmission shaft II15, roller II17 and transmission shaft are arranged in the roller II17. Ⅱ15 is connected by bearing Ⅱ18, and the extended end of the drive shaft Ⅱ15 is connected to the main body of the turning plate Ⅱ10. The rotation of the roller Ⅱ17 drives the movement of the main body of the turning plate Ⅱ10, and finally realizes the process turning function.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com