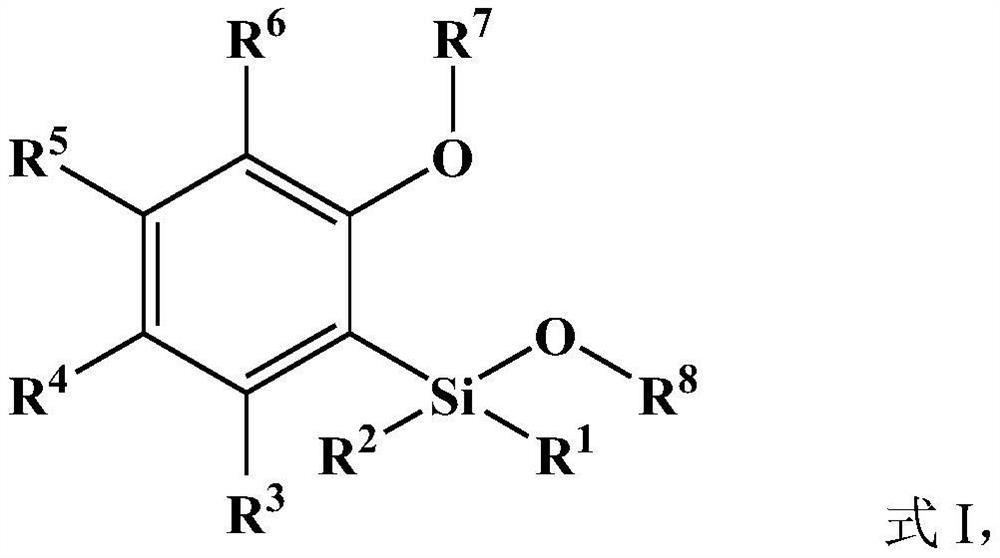

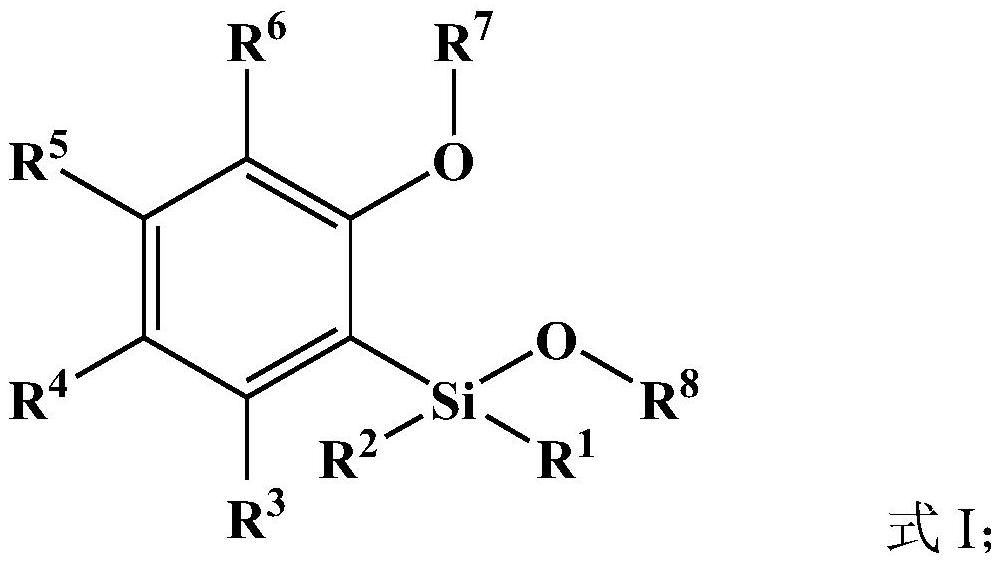

Siza 1,3-diether compound and preparation method thereof, olefin polymerization catalyst and olefin polymerization method

A technology of olefin polymerization and compounds, applied in the field of olefin polymerization, can solve the problems of low melt index and low polymerization efficiency of polyolefins, achieve high catalytic activity, improve polymerization efficiency, and have a wide range of industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] In some embodiments of the present invention, preferably, the preparation method of the solid component comprises:

[0090] (1) dispersing the magnesium-containing compound in a dispersion medium to obtain a magnesium-containing dispersion medium;

[0091] (2) carrying out the fifth contact with the magnesium-containing dispersion medium and the first titanium-containing compound and the first internal electron donor compound to obtain a first dispersion liquid;

[0092] (3) carrying out the sixth contact with the second titanium-containing compound and the second internal electron donor compound to obtain the second dispersion liquid;

[0093] (4) Removing the dispersion medium in the second dispersion liquid to obtain the solid component.

[0094] In some embodiments of the present invention, the magnesium-containing compound is selected from at least one of magnesium chloride, magnesium bromide and magnesium iodide, more preferably magnesium chloride.

[0095] In s...

preparation example 1

[0133] Preparation Example 1 is used to prepare the sila-1,3-diether compound Z1 represented by formula I-1:

[0134]

[0135] (1) Preparation of Grignard reagent

[0136] Take a 500 ml three-necked flask with a magnetron, a spherical condenser and a constant pressure dropping funnel, add magnesium powder (28.8 g, 1.2 mol) and a little iodine under nitrogen protection; add ortho-bromine to the constant pressure dropping funnel Anisole (1.0 mol) and tetrahydrofuran (200 ml), then 5 ml of o-bromoanisole in tetrahydrofuran was added dropwise to the flask, stirred for 3-5 minutes to initiate the reaction; then o-bromoanisole was added dropwise tetrahydrofuran solution; after the dropwise addition is completed, heat under reflux for 1 hour to complete the preparation of Grignard reagent.

[0137] (2) Synthesis of Silane

[0138] Take a 2.5-liter three-necked flask with a magnetron and a spherical condenser, add diphenyldichlorosilane (253 g, 1.0 mol) and 500 mL of tetrahydrofu...

preparation example 2

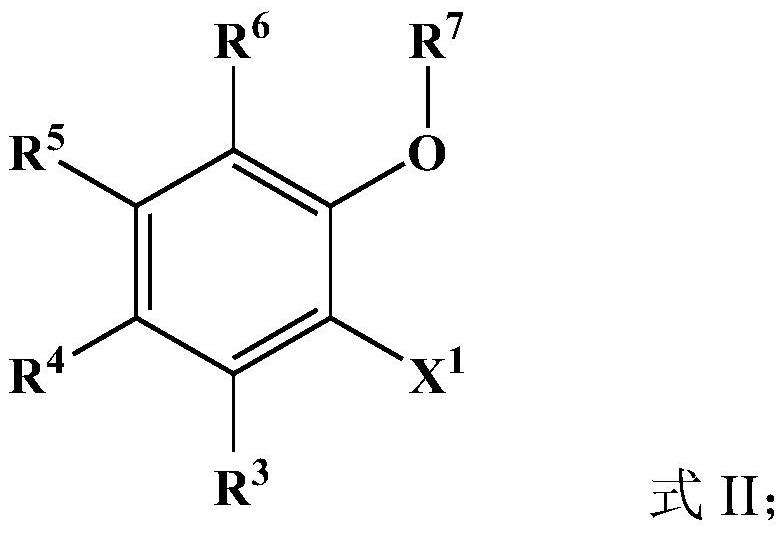

[0140] Preparation Example 2 is used to prepare the sila 1,3-diether compound Z2 represented by formula I-2:

[0141]

[0142] According to the method of Preparation Example 1, the difference is that in step (2), an equivalent amount of diisopropyldichlorosilane is used instead of diphenyldichlorosilane, and the obtained product is determined to be formula I-2 by hydrogen nuclear magnetic resonance spectrum Compound Z2 shown (81 wt% yield).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com