Natural gas diffusion amount monitoring device and method in gas pipeline construction process

A gas pipeline and monitoring device technology, which is applied in the pipeline system, gas/liquid distribution and storage, instruments, etc., can solve the problems of error, frictional resistance of the pipeline to be replaced, and the inability to obtain the actual pressure of the pipeline, etc., to achieve instantaneous component accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

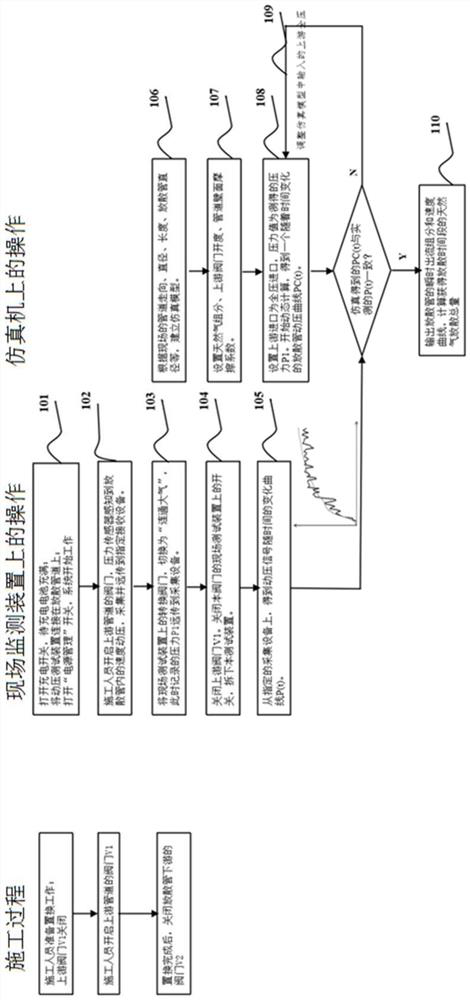

[0044] The invention combines fluid simulation technology with on-site actual measurement, not only can clearly give pipeline pressure through actual measurement, but also can verify data such as flow velocity and dynamic pressure obtained by simulation according to actual measurement results. It has the advantages of easy operation and remote recording, and can accurately show the amount of natural gas released during each replacement process.

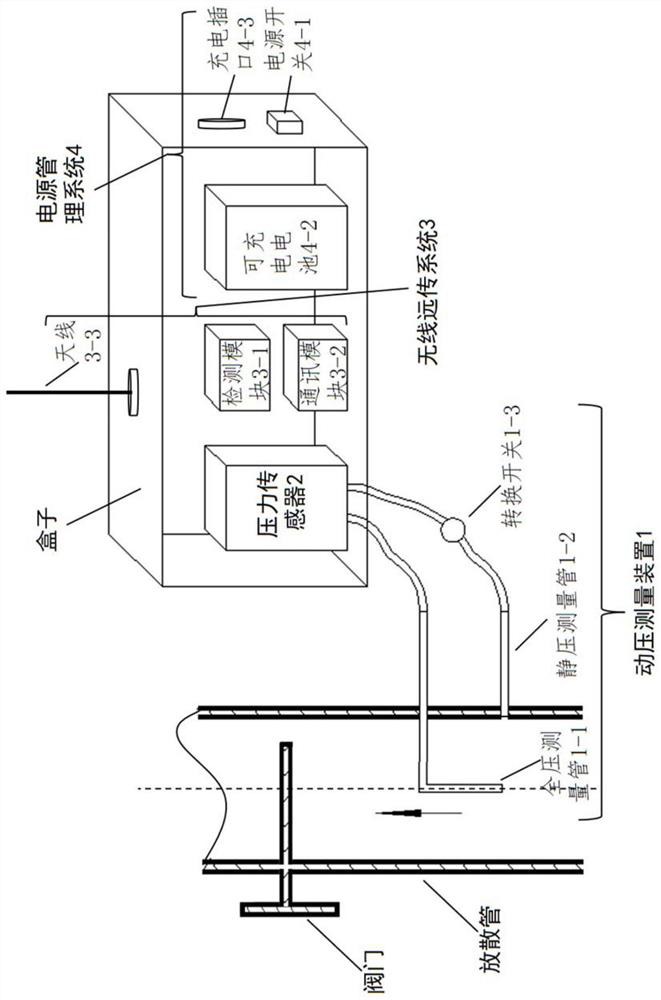

[0045] Such as figure 1 As shown, the present invention provides a gas pipeline construction process natural gas emission monitoring device, which consists of four parts, including a dynamic pressure measurement component 1, a pressure sensor 2, a wireless remote transmission component 3 and a power management component 4.

[0046] The dynamic pressure measurement assembly 1 includes a total pressure measurement tube 1-1, a static pressure measurement tube 1-2 and a transfer switch 1-3.

[0047] The pressure sensor 2 includes a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com