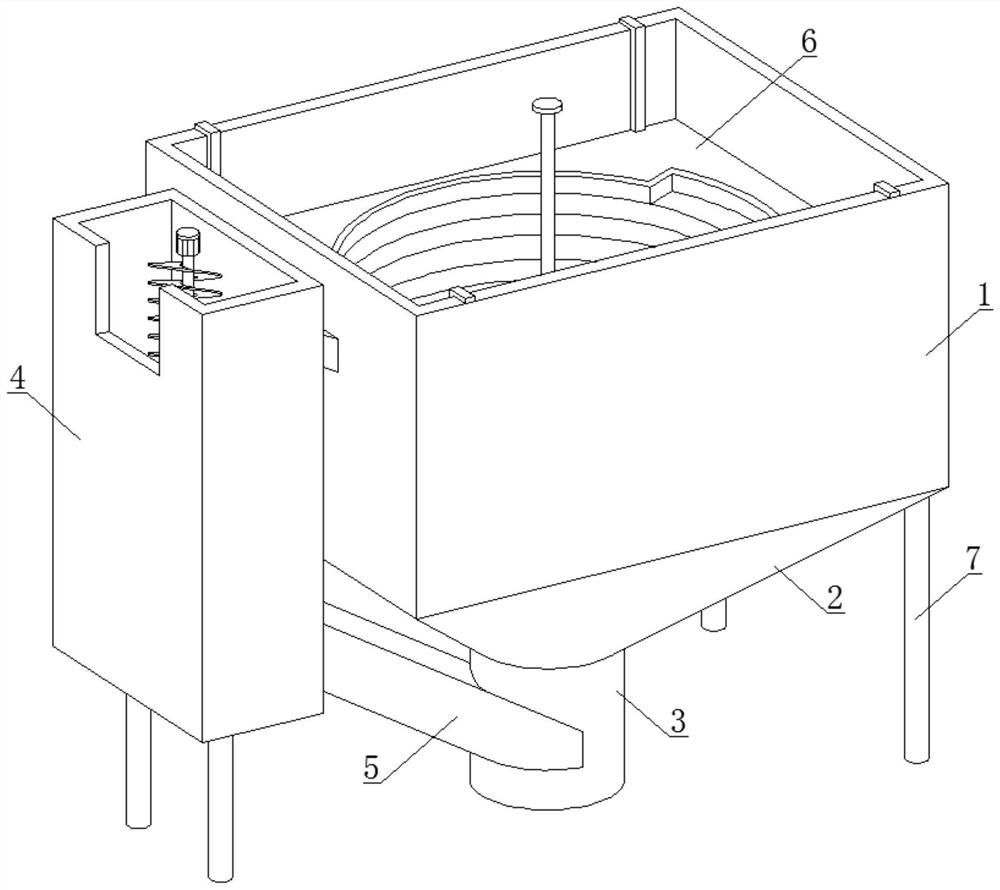

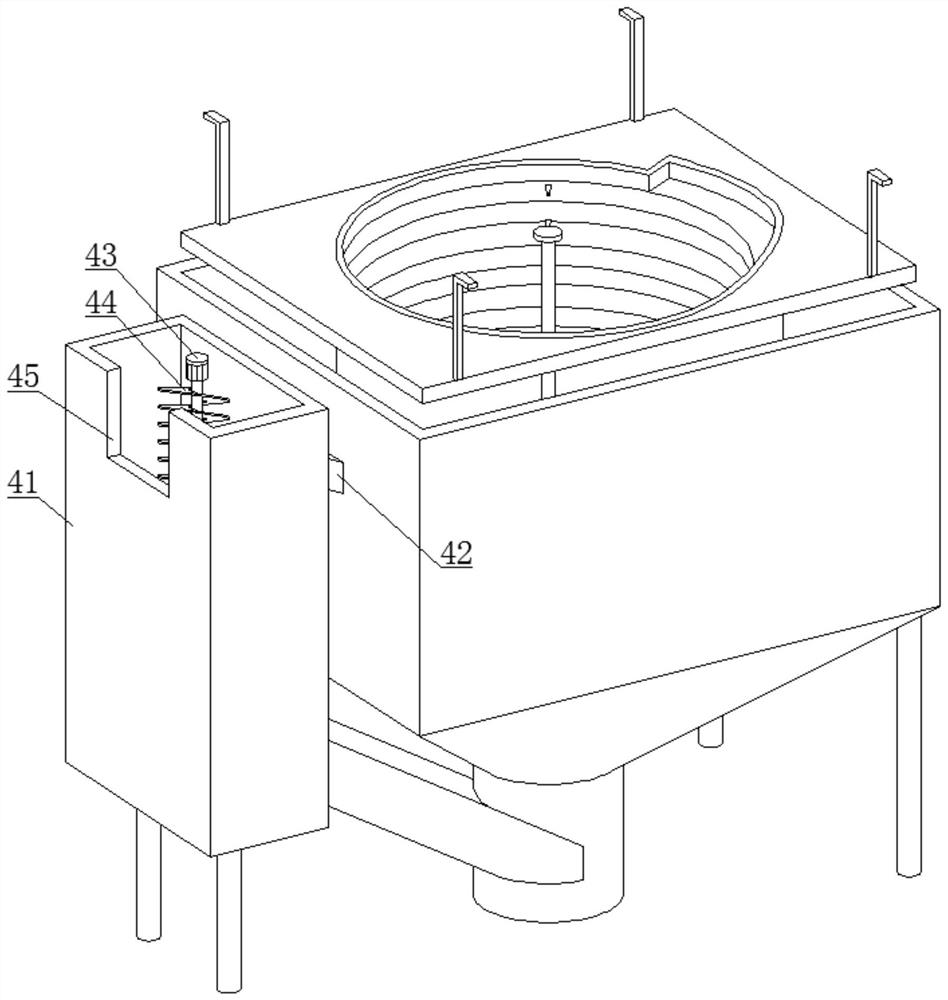

Spiral-flow type desilting device for water conservancy project construction and implementation method thereof

A water conservancy engineering and swirling flow technology, which is applied in the field of swirling sand settling devices for water conservancy project construction, can solve the problems of trouble, easy doping, poor use effect, etc., and achieves good separation effect and high sand settling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , 1 Embodiment approach

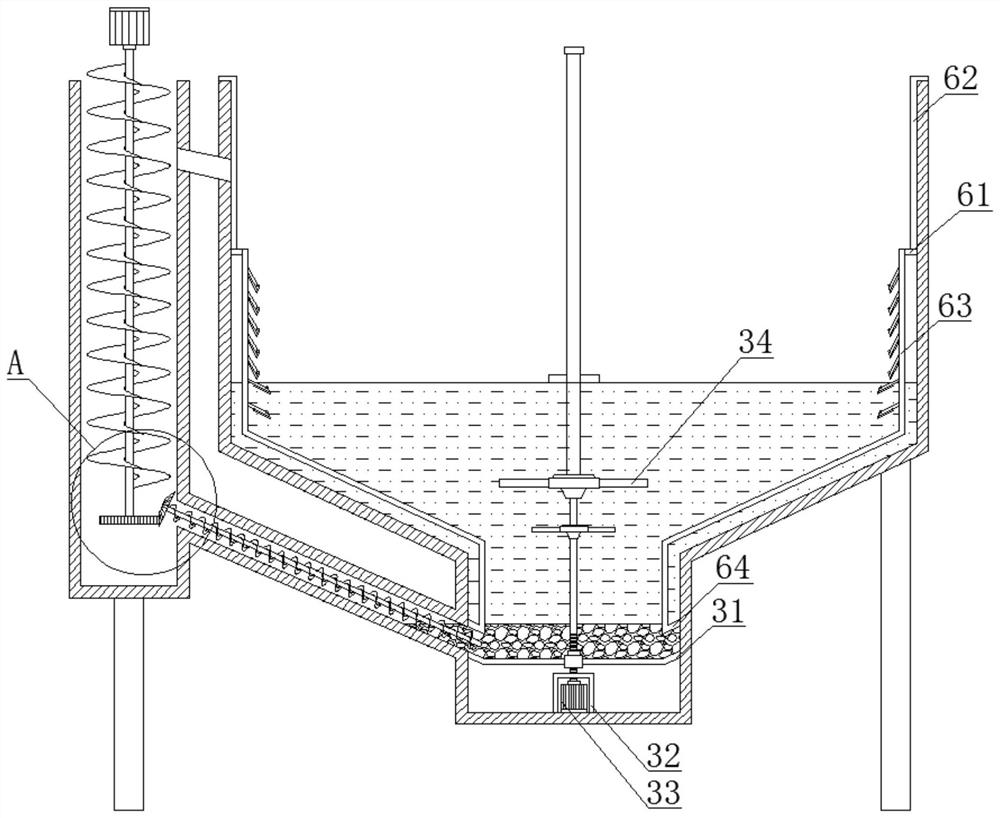

[0040] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing a cyclone type sedimentation device for water conservancy construction, comprising the following steps:

[0041] Step 1: The operator places the device at the place where sand needs to be settling, and fixes it on the ground with the plug-in 7;

[0042] Step 2: pour water containing sand into the box 1, the water in the box 1 flows into the inner cylinder 63, and enters in a swirling flow along the spiral pattern 632;

[0043] Step 3: Turn on the motor B33 to work, so that the swirl blades A343 and B344 on the outer surface of the strut 341 and the strut 341 rotate, the water inside the inner cylinder 63 rotates all the time, and the sand is deposited in the sand chamber 3. And accumulated in the upper end of the negative pressure cover 311;

[0044] Step 4: Turn on the motor A43 to make the screw rod A44 rotate, and use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com