Self-tracing lifting device with supporting frame

A lifting device and support frame technology, which is applied to lifting devices, transportation and packaging, electric vehicles, etc., can solve the problems of unsuitable construction, high manufacturing and maintenance costs, and inconvenient operation, and achieve convenient and high-density layout, stable and reliable. Support, flexible and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

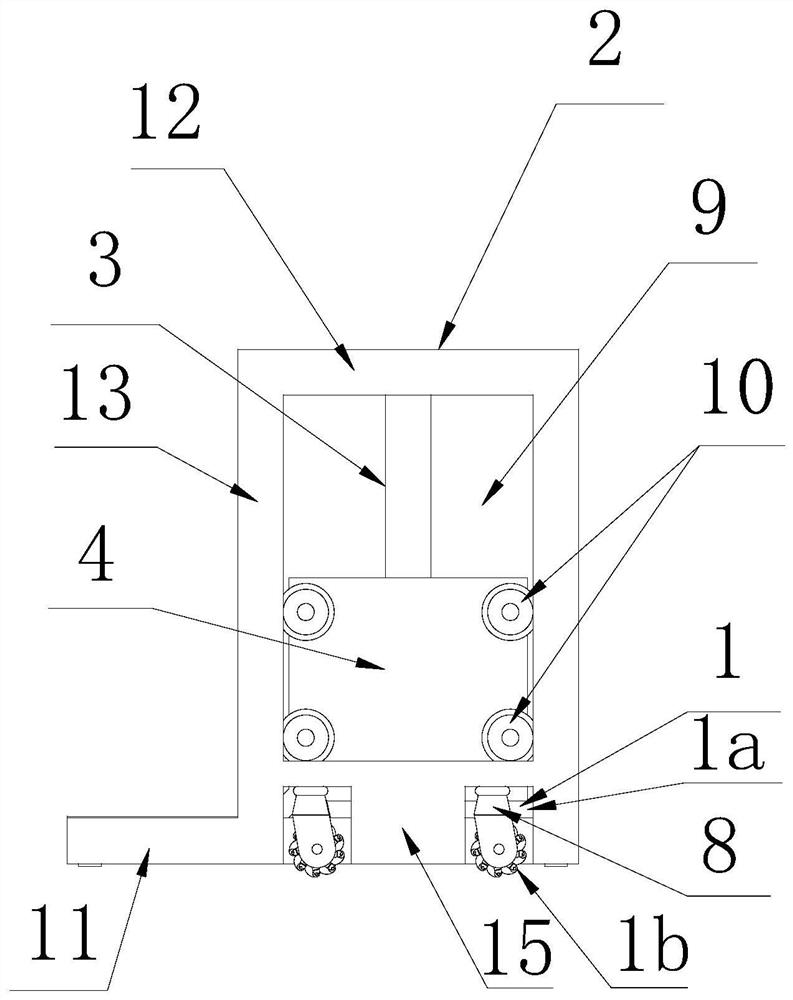

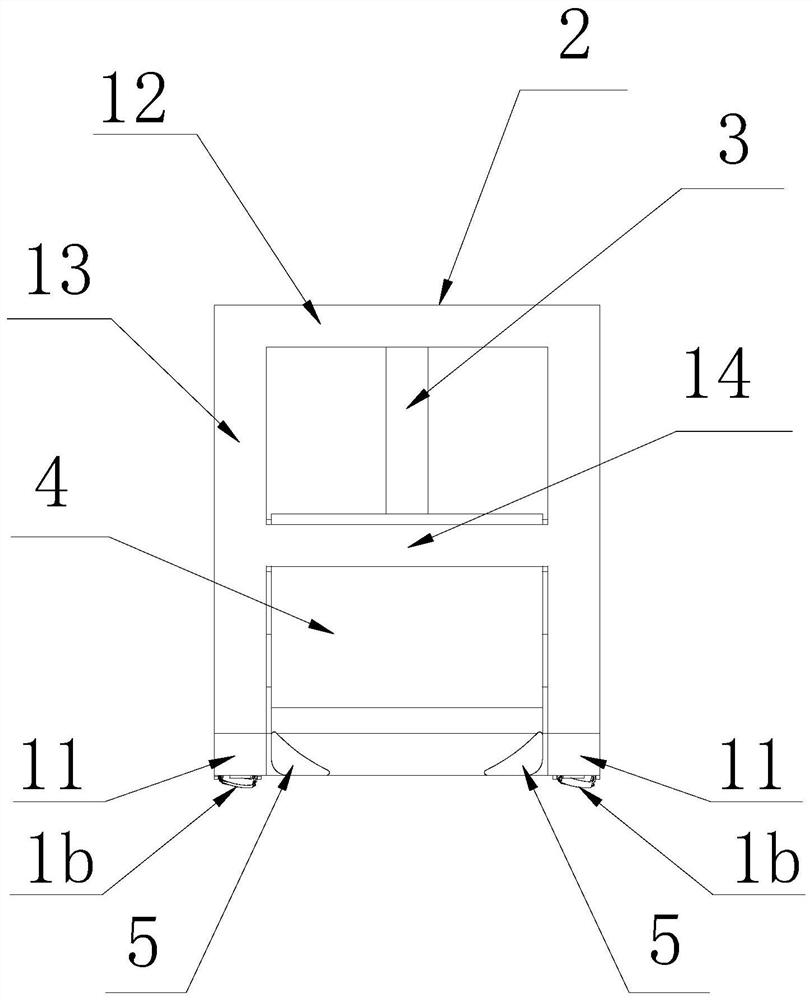

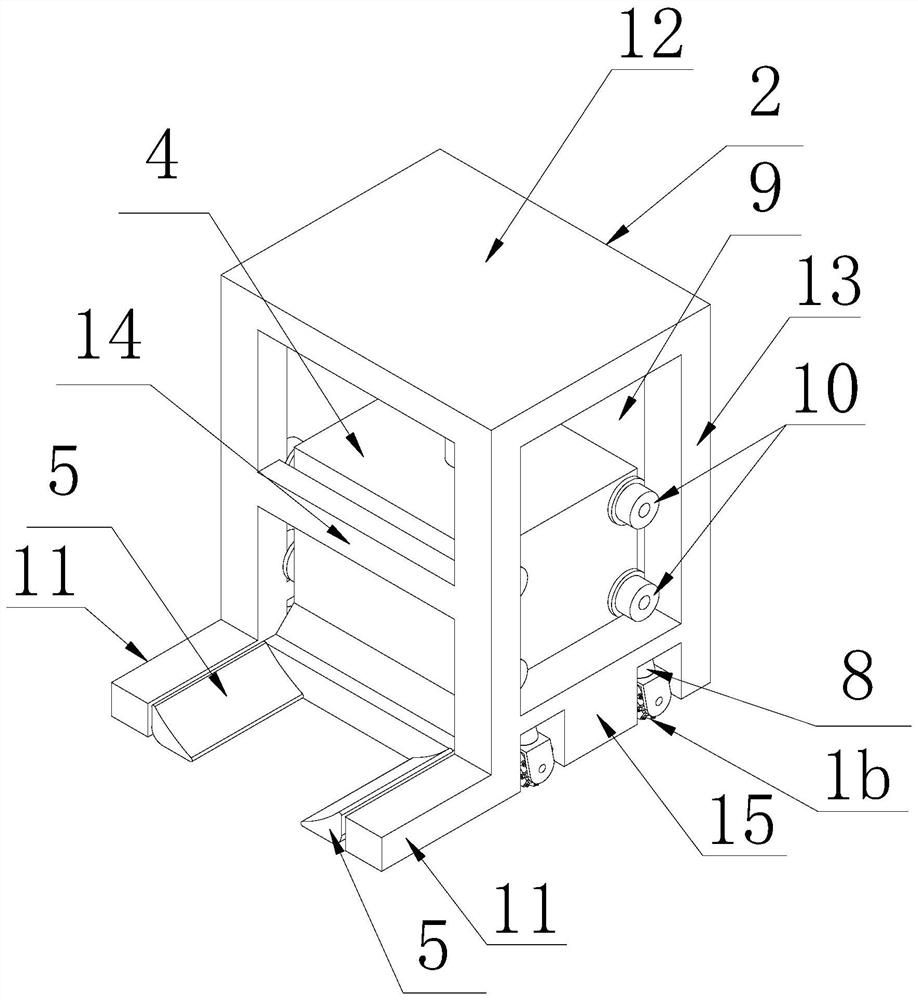

[0054] Example 1: Combining Figure 1~Figure 10 A specific implementation of the self-tracking lifting device with a support frame provided by the present invention is described as follows:

[0055] first as Figure 1~Figure 4 As shown, this self-tracking lifting device with a support frame is composed of two parts: a traveling mechanism and a lifting mechanism. Together with two wheel support rods 5 fixed on the front portion of the lifting block 4, the two wheel support rods 5 are parallel and horizontally arranged, and are used to reach the bottom of the wheel 7 of the automobile 6 to lift the wheel 7.

[0056] The AGV trolley 1 is composed of a flat-shaped body 1a and four traveling wheels 1b installed at the bottom of the body 1a. A feature of the design of this embodiment is that the AGV trolley 1 and the support frame 2 are designed in one piece, and the body 1a The four traveling wheels 1b at the bottom all adopt floating installation. In addition, the walking wheel...

Embodiment 2

[0071] Example 2: Combining Figure 11~Figure 15Shown, is another embodiment of the present invention, and its whole is the same as embodiment 1, also is made up of two parts of running mechanism and lifting mechanism, and wherein running mechanism is AGV trolley 1, and lifting mechanism then is then by supporting frame 2, The lifting drive device 3, the lifting block 4 and the two wheel support rods 5 fixed on the front part of the lifting block 4 are jointly composed, and the two wheel support rods 5 are arranged in parallel and horizontally, and are used to extend to the bottom of the wheel 7 of the automobile 6 to lift wheel7.

[0072] The AGV trolley 1 is composed of a flat body 1a and a plurality of walking wheels 1b installed at the bottom of the vehicle body 1a. The design of this embodiment is different from that of the embodiment 1 in that the AGV trolley 1 and the support frame 2 adopt Split design, and the support frame 2 is installed floatingly on the body 1a of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com