Cabinet installation and connection accessory

A technology for connecting components and accessories, which is applied in the direction of switchgear, electrical components, substation/power distribution device shells, etc., which can solve the problems of inability to provide help for wiring of power distribution cabinets, difficulties in installation and maintenance of cabinets, irregular and irregular power distribution cabinets and other problems, to achieve the effect of convenient passage and centralized convergence, reasonable and beautiful wiring technology, and increased operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

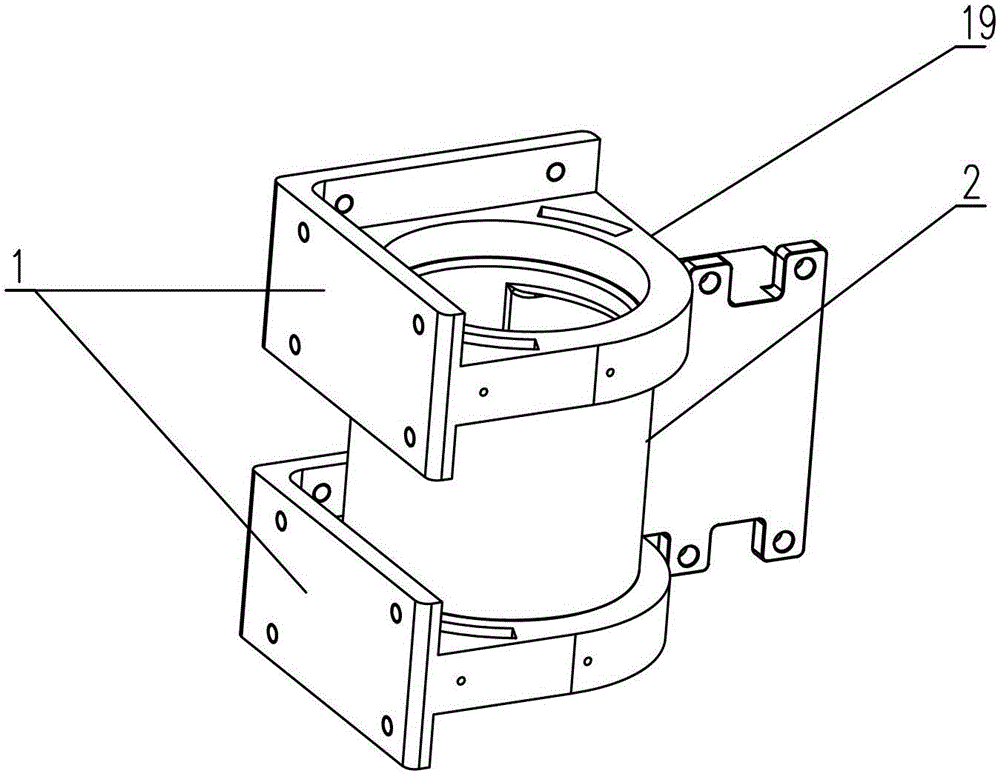

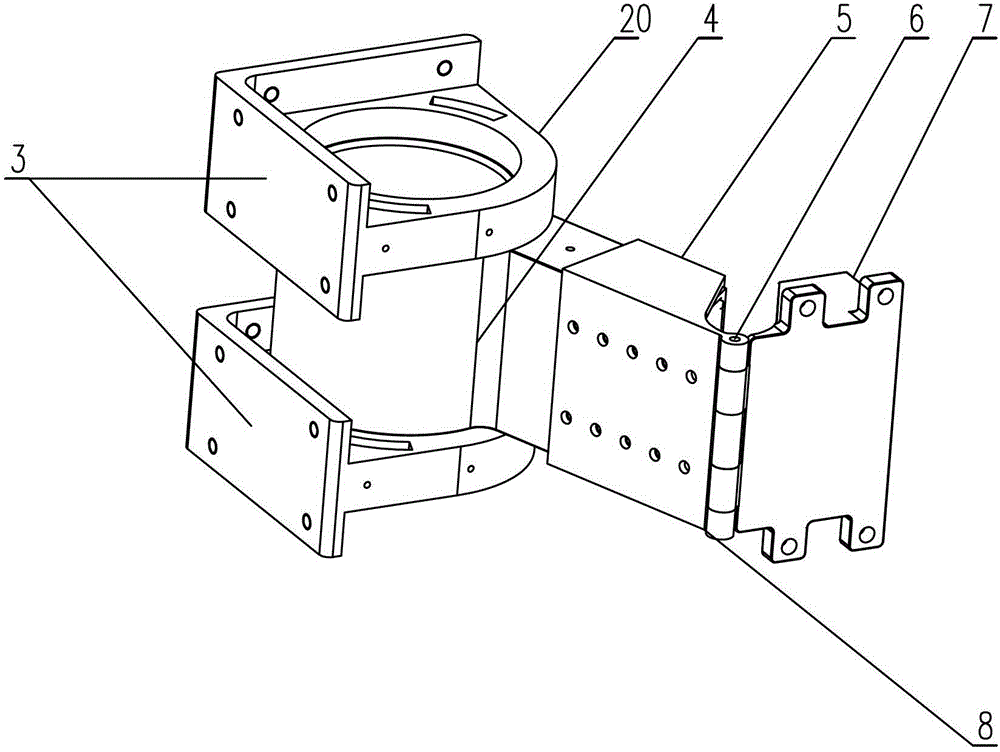

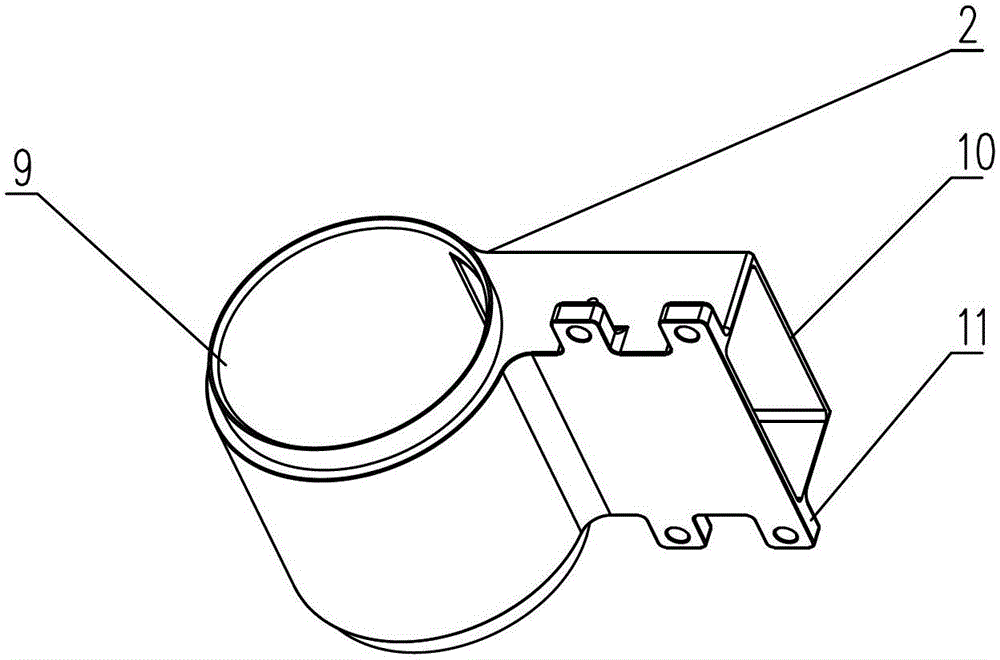

[0026] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 The shown cabinet installation and connection accessories are characterized in that they include a connection assembly I19 and a connection assembly II20; Connected fixed shaft sleeve I1; the assembly line assembly I2 includes a cylinder I9 and a rectangular groove I10 communicated with the cylinder I9 on the side wall of the cylinder I9; the side wall of the rectangular groove I10 is provided with 4 and The fixed hole provided on the first mounting plate 22 is provided with the protruding fixing part I11 matched with the installation; the fixed bushing I1 has a cylinder II13 whose inner diameter matches the outer diameter of the cylinder I9 and two rectangular sides vertically connected to each other Wall 12; the rectangular side wall 12 is provided with mounting holes matching the fixing holes provided on the coupling assembly fixing frame 21; two fixed bushings I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com