A gas extraction borehole plugging device and using method

A plugging device and gas drainage technology, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve the problems of plugging bags on both sides falling off, drilling holes on both sides of the plugging area collapse, etc., to achieve prevention and control The effect of drilling collapsed holes, improving the efficiency of gas drainage, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, one embodiment of the present invention is further described:

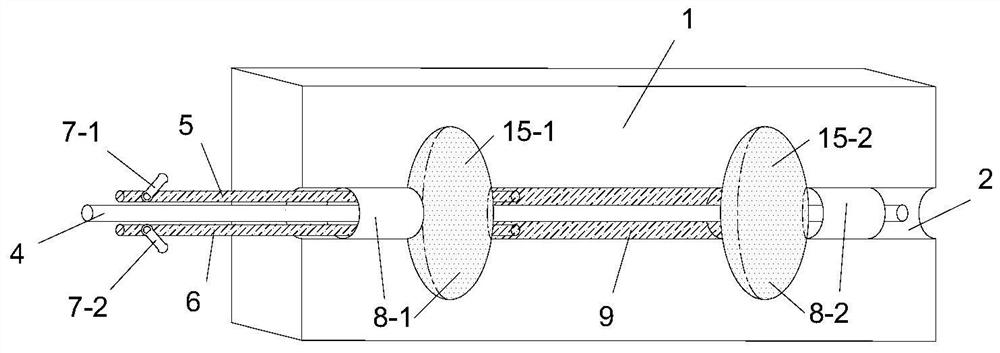

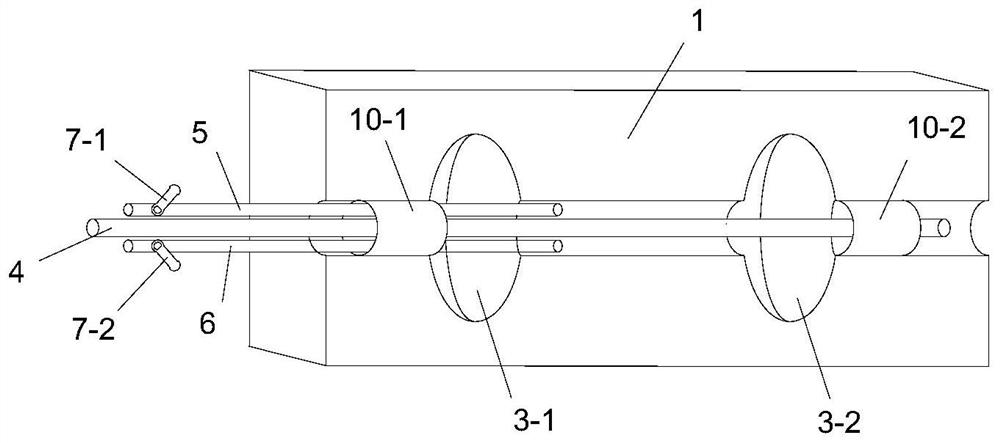

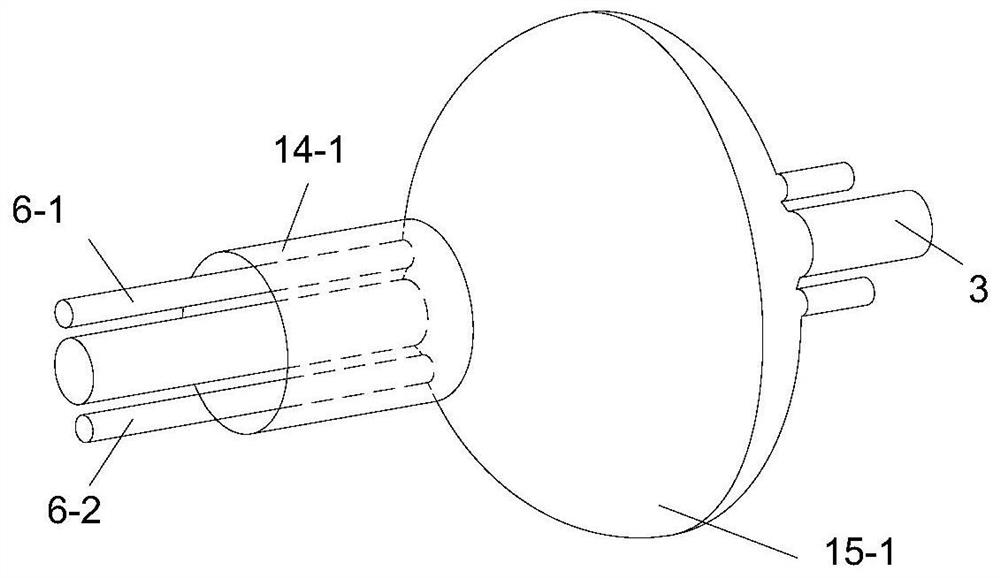

[0020] Figures 1 to 5 As shown, the gas drainage borehole plugging device of the present invention includes a gas drainage pipeline 4 sheathed with a 'flat spherical'-shaped plugging device 1 8-1 and a 'flat spherical'-shaped plugging device 2 8-2. The 'oblate spheroid'-shaped plugging device 1 8-1 and the 'oblate spheroid'-shaped plugging device 2 8-2 are respectively completely filled with spheroid borehole 1 3-1 and spheroid borehole 2 3-2, gas drainage pipeline 4 The upper and lower ends are provided with a grouting pipe 5 and a grouting pipe 6. One end of the grouting pipe 5 and the grouting pipe 6 passes through the 'flat ball'-shaped plugging device 1 8-1, and goes deep into the 'flat sphere'-shaped plugging device 1 8 Between -1 and the 'flat ball'-shaped blocking device 2 8-2, the other ends are respectively connected with valve 1 7-1 and valve 2 7-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com