Method for carrying out a shifting operation in a sequential manual transmission

A transmission, sequential technology, applied in the direction of elements with teeth, belt/chain/gear, mechanical equipment, etc., can solve the problems of expensive, large system, etc., to achieve the effect of improving driving and shifting comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

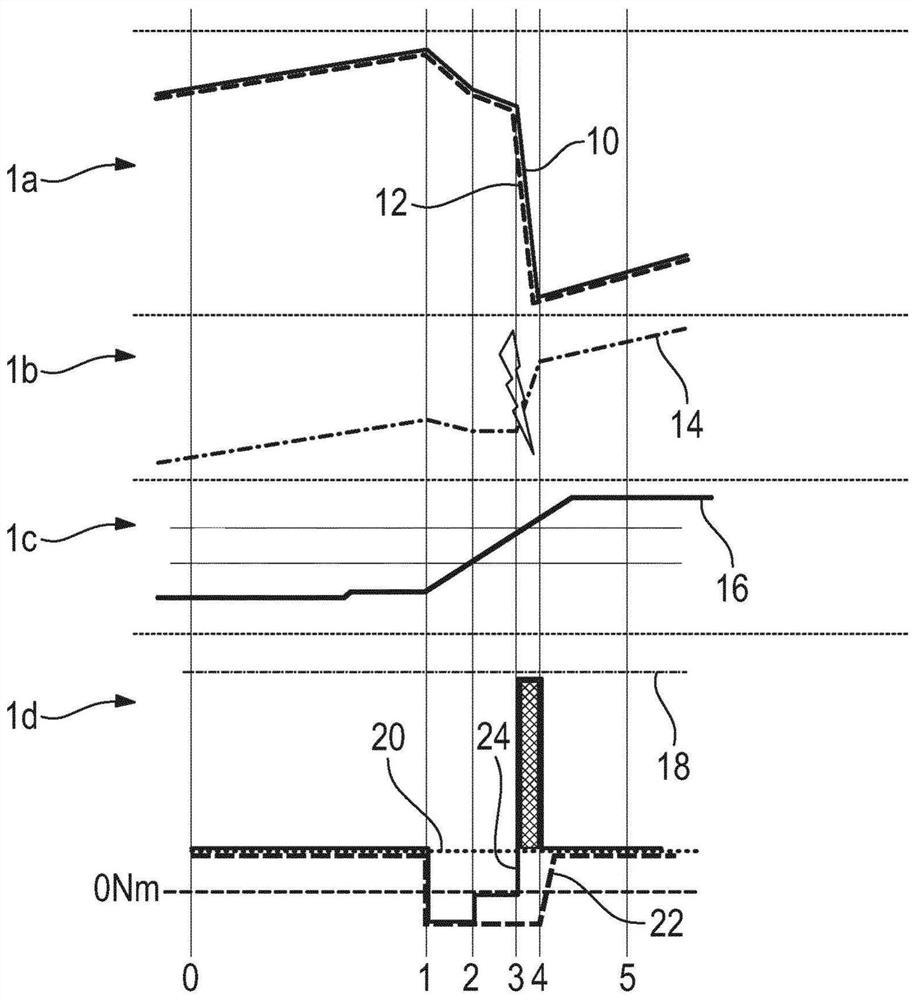

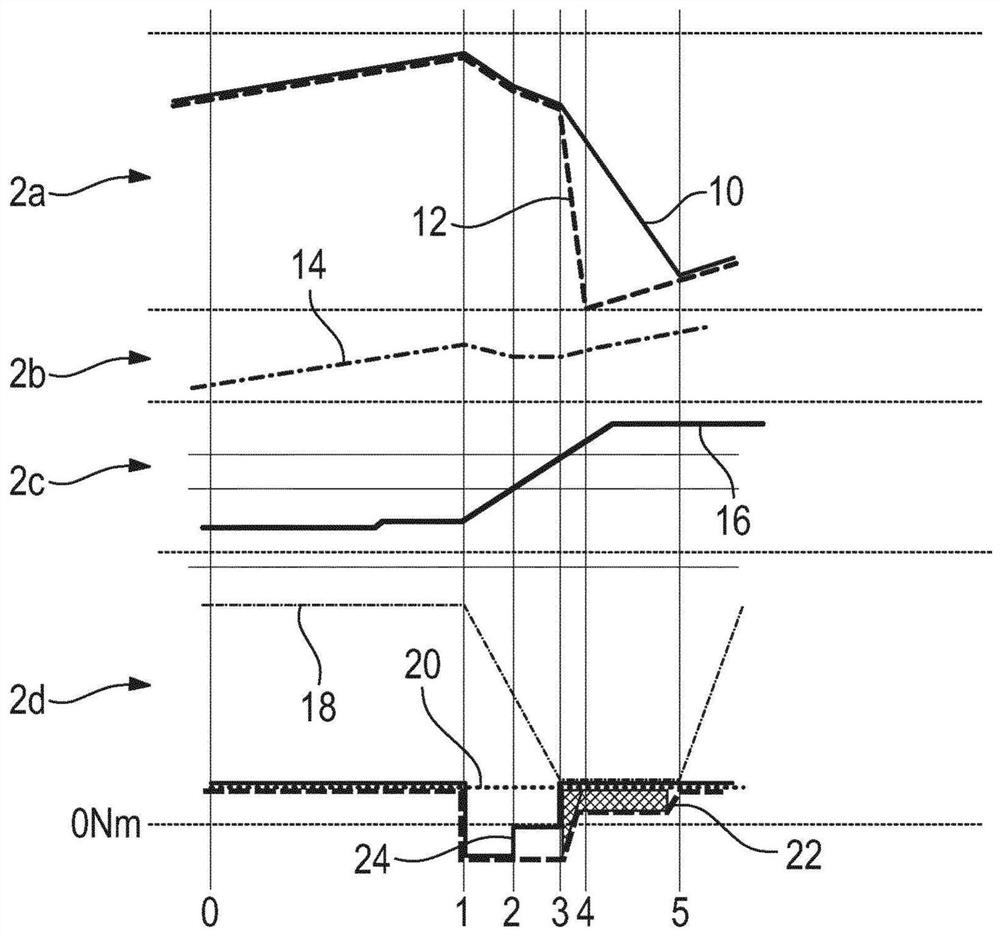

[0026] figure 1 The sequence of the method for carrying out the shifting process in the case of an upshift from gear X into gear X+1 in a sequential transmission, such as a shift dog transmission, is clearly shown. The shifting process can be carried out automatically, partially automatically or manually. The shifting process takes place in particular without actuating the clutch.

[0027] Sequential transmissions are sufficiently known to those skilled in the art that a detailed description is therefore omitted.

[0028] exist figure 1 , the process of the method is divided into time segments. The curves of different characteristic variables are shown schematically here.

[0029] Normal driving operation takes place from time 0 to time 1, that is to say, while gear X is engaged, in particular without shifting to a higher or lower gear, the driver makes the vehicle accelerate.

[0030] Corresponding to the acceleration adjusted by the driver via the throttle control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com