Carbon-based intermetallic compound nano material as well as preparation method and application thereof

An intermetallic compound and nanomaterial technology, applied in the field of nanomaterials, can solve problems such as worrying application prospects, complex preparation processes, and expensive raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The application also provides a method for preparing carbon-based intermetallic compound nanomaterials, comprising the following steps:

[0040]A) mixing porous carbon Black Pearls 2000, a metal salt precursor and a solvent to obtain an initial mixture; the metal salt precursor is a Rh base salt and other metal salts;

[0041] B) heat-treating the initial mixture under a reducing atmosphere to obtain carbon-based intermetallic compound nanomaterials.

[0042] According to the above preparation method, the preparation method of the carbon-based intermetallic compound nanomaterial provided by the present application can be prepared only by dipping and heat treatment. This method is universally applicable to various metals, and the process operation is simple and easy.

[0043] Specifically, in the process of preparing carbon-based intermetallic compound nanomaterials, the applicant first mixes porous carbon BlackPearls 2000, metal salt precursor and solvent, and obtains t...

Embodiment 1

[0053] a. Mix 50mg of porous carbon material with appropriate amount of C 15 h 21 o 6 Rh and TiCl 4 (Guaranteed Rh / Ti atomic ratio = 3 / 1, and the total loading of Rh and Ti is 15wt%) Place in a 100ml round bottom flask, add solvent ethanol, stir for 6-10h, and after rotary evaporation and drying, a uniformly mixed precursor is obtained body;

[0054] b. Put the precursor into the tube furnace, feed the argon-hydrogen mixture into the tube furnace as a protective gas, raise the temperature of the tube furnace to 1000 °C at a rate of 5 °C / min, and keep it for 2 hours; At room temperature, keep the normal pressure in the tube furnace to get Rh 3 Ti intermetallic compound nanocatalyst.

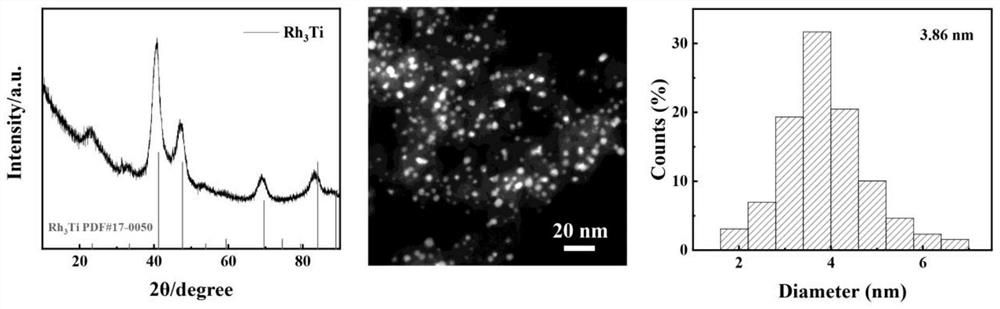

[0055] figure 1 Rh provided for Example 1 of the present invention 3 Rh in Ti intermetallic nanocatalysts 3 XRD, HAADF-STEM and particle size distribution photos of Ti intermetallic phase;

[0056] It can be seen from XRD that the material matches Rh 3 Ti standard PDF card; HAADF-STEM sh...

Embodiment 2

[0058] a. Mix 50 mg of porous carbon material with appropriate amount of RhCl 3 ·3H 2 O and VCl 3 (Guaranteed Rh / V atomic ratio = 3 / 1, and the total loading of Rh and V is 15wt%) Place in a 100ml round bottom flask, add solvent water, stir for 6-10h, and after rotary evaporation and drying, a uniformly mixed precursor is obtained body;

[0059] b. Put the precursor into the tube furnace, feed the argon-hydrogen mixture into the tube furnace as a protective gas, raise the temperature of the tube furnace to 1000 °C at a rate of 5 °C / min, and keep it for 2 hours; At room temperature, keep the normal pressure in the tube furnace to get Rh 3 V intermetallic nanocatalysts.

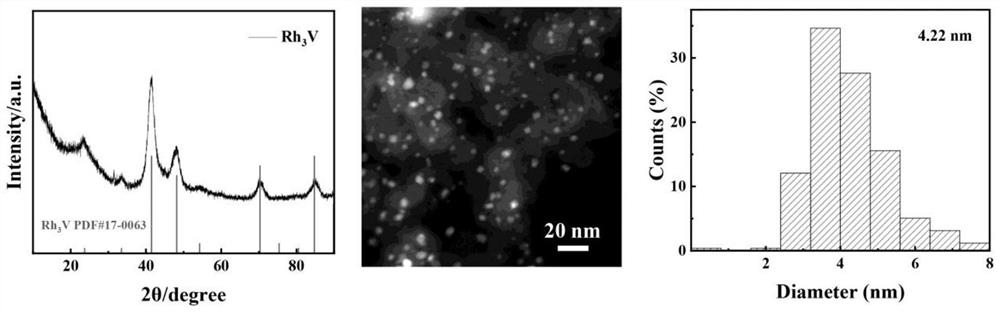

[0060] figure 2 Rh provided for embodiment 2 of the present invention 3 Rh in intermetallic nanocatalysts 3 XRD, HAADF-STEM and particle size distribution photos of V intermetallic phase;

[0061] It can be seen from XRD that the material matches Rh 3 V standard PDF card; HAADF-STEM shows that the aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com