Preparation method of layered nano-nickel cobalt lithium aluminate as positive electrode material for lithium ion battery

A cathode material layer, lithium ion battery technology, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology and other directions, can solve the problems of complex preparation process, achieve simple recovery method, good electrochemical performance, Conditional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Aiming at the defect that the preparation process of the prior art method is complicated, a typical embodiment of the present invention provides a method for preparing a lithium-ion battery positive electrode material layered nano-nickel-cobalt lithium aluminate, including:

[0034] Step 1, preparing a nano nickel cobalt aluminum hydroxide precursor.

[0035] a) Dissolving soluble nickel salt, cobalt salt and aluminum salt in deionized water to prepare mixed metal salt solution A with a total metal ion concentration of 0.2-2mol / L.

[0036] b) Sodium hydroxide is dissolved in deionized water to prepare a precipitant solution with a concentration of 1-10mol / L, and ammonia water with a concentration of 0.1-1mol / L is used as a complexing agent, and the precipitant and complexing agent are mixed by volume The ratio is 2-4 to prepare mixed solution B containing complexing agent and precipitating agent.

[0037] c) Mix the mixed metal salt solution A, the organic phase, the s...

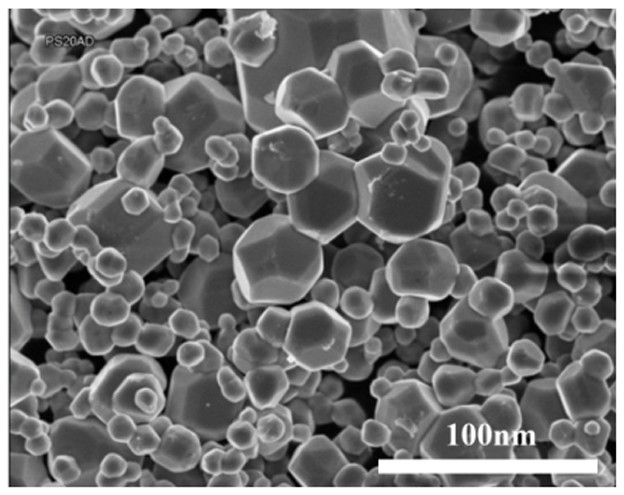

Embodiment 1

[0056] Dissolve nickel sulfate, cobalt sulfate and aluminum sulfate in deionized water to configure mixed metal salt solution A. The total ion concentration of Ni+Co+Al is 0.2mol / L, where Ni:Co:Al (mass ratio) =80:15:5.

[0057] Prepare 30 mL of 1 mol / L sodium hydroxide aqueous solution, and add 15 mL of ammonia solution with a mass concentration of 0.1 mol / L to form a mixed solution B containing complexing agent and precipitating agent.

[0058] Add 100g cetyltrimethylammonium bromide (surfactant, HLB value 15.8) and 100mL n-butanol (as co-surfactant and organic phase) to the above 50mL mixed metal salt solution A, at 500rmp Stir for 20 min to form a homogeneous mixture C. The ammonia-alkali mixed solution B is added in the above-mentioned mixed solution C by a peristaltic pump at a rate of 150ml / h, and is stirred with a stirring rate of 500rmp while adding dropwise, and the pH value of the system is strictly controlled in the reaction process, so that the pH of the system= ...

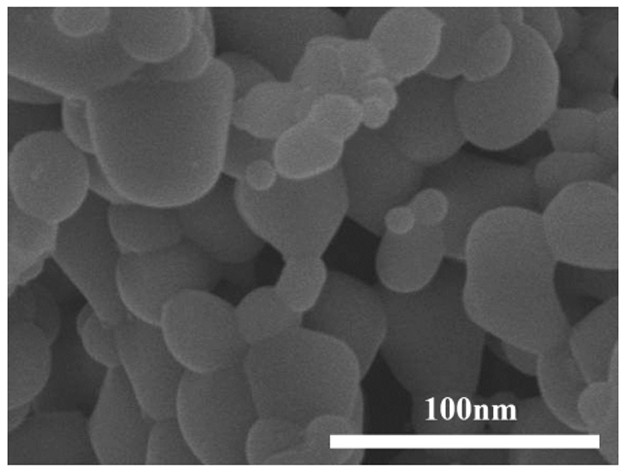

Embodiment 2

[0064] Dissolve nickel nitrate, cobalt nitrate and aluminum nitrate in deionized water to configure mixed metal salt solution A. The total ion concentration of Ni+Co+Al is 0.6mol / L, where Ni:Co:Al (mass ratio) =75:15:10.

[0065] Prepare 30 mL of 5 mol / L sodium hydroxide aqueous solution, and add 15 mL of ammonia solution with a mass concentration of 0.5 mol / L to form a mixed solution B containing complexing agent and precipitating agent.

[0066] Add 80g of polyoxyethylene alkyl aryl ether (surfactant, HLB value 13) and 120mL of n-hexanol (as a co-surfactant and organic phase) into the above 50mL mixed metal salt solution A, and stir at 400rmp for 25min A homogeneous mixture C is formed. The ammonia-alkali mixed aqueous solution B is added in the above-mentioned mixed solution C by a peristaltic pump at a rate of 100ml / h, and is stirred with a stirring rate of 400rmp while adding dropwise, and the pH value of the system is strictly controlled in the reaction process, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com