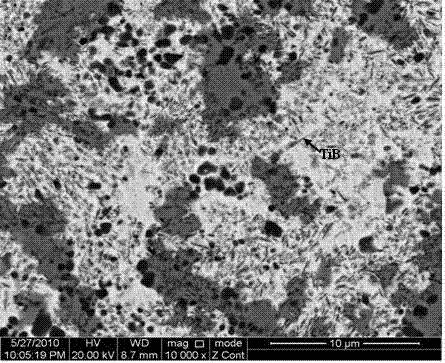

Method for improving strength of ceramic soldered joint by in-situ self-generated TiB whiskers

A brazed joint, in-situ self-generating technology, which is applied in the field of preparation of ceramic brazed joints, can solve the problems such as the reinforcement phase and the matrix are not easily wetted, the joint stress is large, segregation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

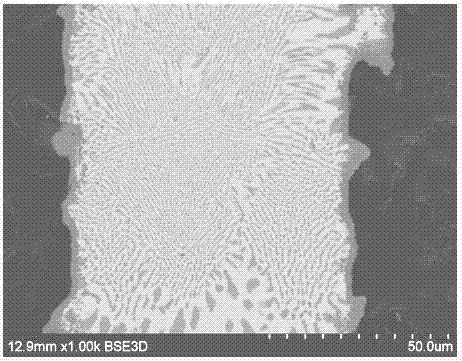

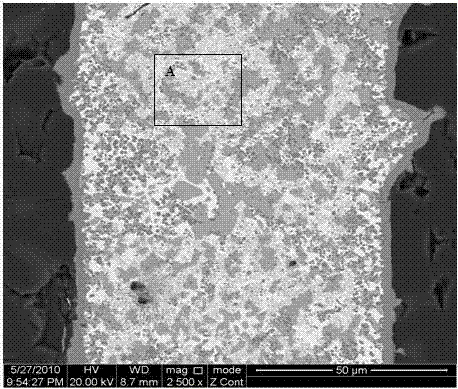

[0008] Specific implementation mode 1: A method for improving the strength of ceramic brazing joints by in-situ self-generated TiB whiskers in this embodiment is carried out according to the following steps: 1. Weigh 40% to 75% of Ag powder, 20% to 40% by mass percentage % Cu powder, 1% ~ 10% TiB 2 Powder and 4%~10% TiH 2 powder and put it into a ball mill, and under the protection of Ar gas, ball mill at a speed of 300 rpm to 350 rpm for 1h to 5h to obtain a composite solder; 2. Clean and dry the surface of the ceramic part to be welded with acetone 3. Take by weighing the composite solder and the binder obtained in step 1 by the volume ratio of the composite solder and the binder, and mix the composite solder and the binder evenly, and coat it on the On the surface to be welded of the ceramic part processed in step 2, the thickness of the coating layer is 100 μm to 300 μm to obtain the piece to be welded; 4. Put the piece to be welded obtained through step 3 into a vacuum b...

specific Embodiment approach 2

[0010] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the binding agent described in the step 3 consists of 1% glycerol, 3% distilled water and 96% hydroxyethyl cellulose by mass percentage mixed. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, 41% to 71% of Ag powder, 22% to 35% of Cu powder, 2% to 8% TiB 2 powder and 5% to 8% TiH 2 pink. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com