Ultrathin ZIF-67 nanosheet and preparation method thereof

A ZIF-67, nanosheet technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of rare exploration of ZIF-67 nanomaterials, unfavorable material dispersion and film forming treatment, It is not conducive to large-scale preparation and other problems, and achieves the effects of low preparation cost, high repetition rate, and improved device performance and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

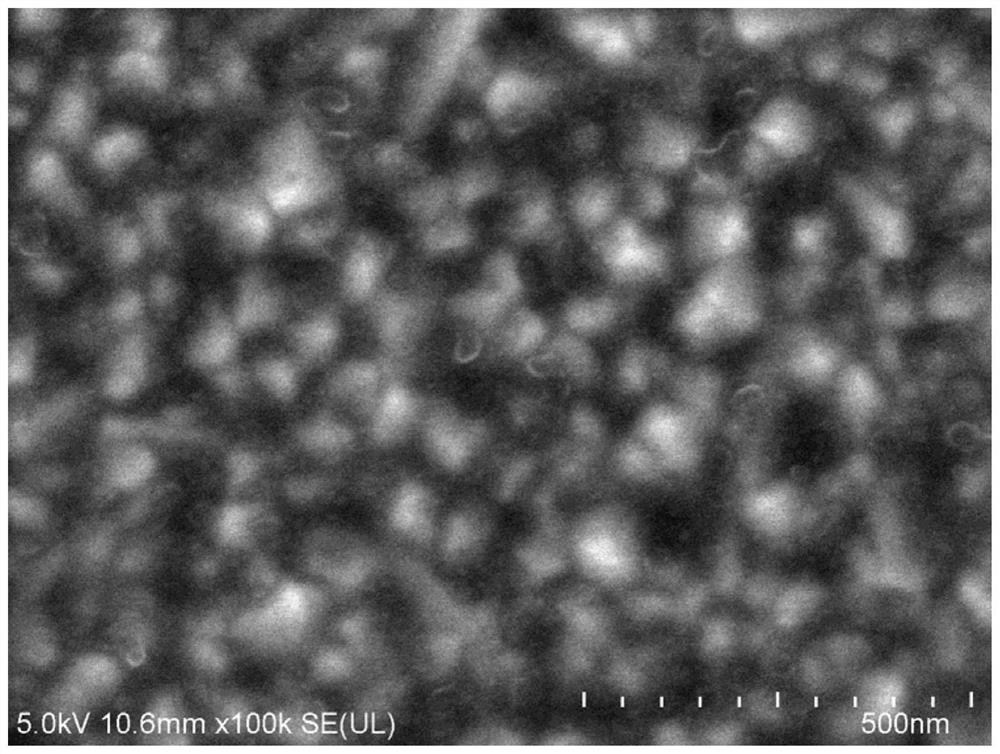

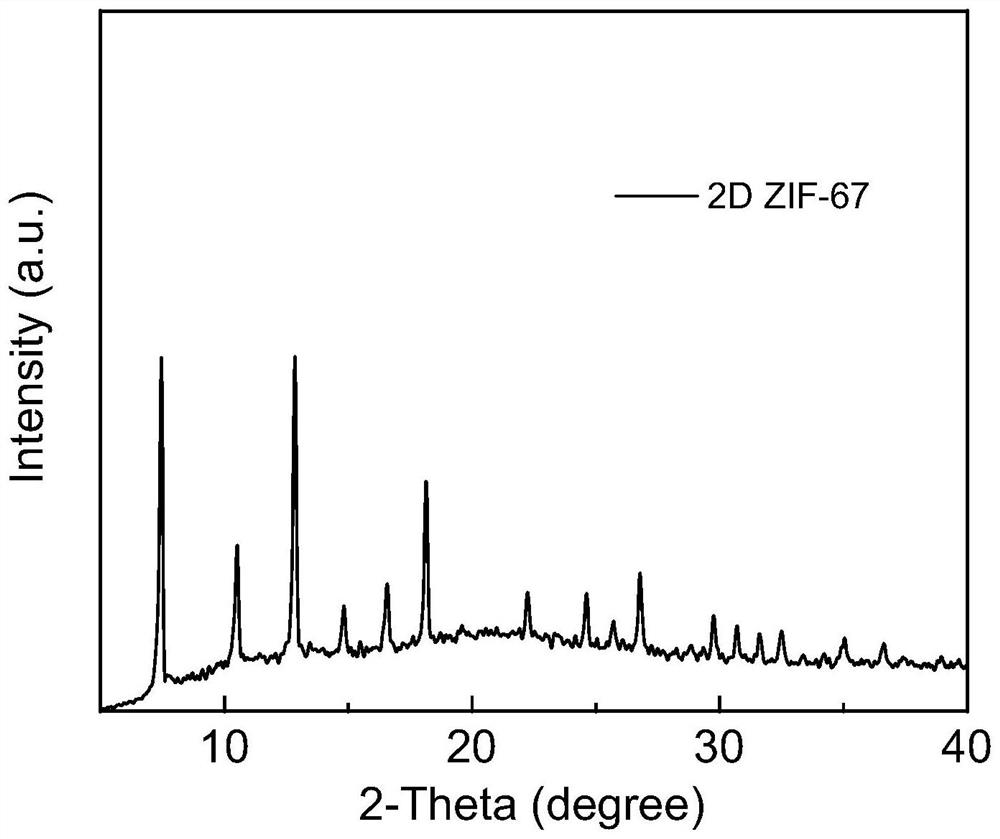

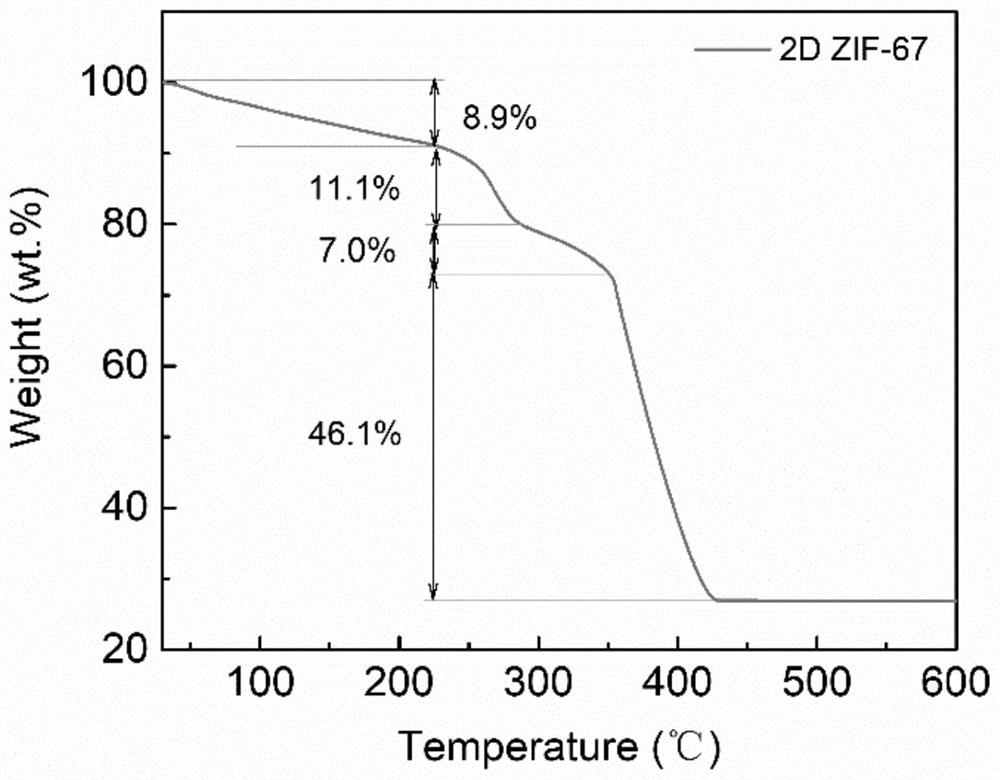

Image

Examples

preparation example Construction

[0040] The invention provides a room temperature preparation method of ultra-thin ZIF-67 nanosheets, comprising the following steps:

[0041] (1) dissolving the cobalt salt in a mixed solvent of absolute ethanol and N,N-dimethylformamide, and mixing to obtain a cobalt salt solution;

[0042] (2) Dissolving dimethylimidazole in a mixed solvent of absolute ethanol and N,N-dimethylformamide, and mixing to obtain a dimethylimidazole solution;

[0043] (3) adding the cobalt salt solution that step (1) obtains to the dimethylimidazole solution that step (2) obtains and reacting, standing and aging after the reaction, and post-processing to obtain ultra-thin ZIF-67 nanosheets;

[0044] The whole process is carried out at room temperature.

[0045] In one embodiment of the present invention, in step (1), the cobalt salt is selected from one or more of cobalt nitrate hexahydrate or cobalt chloride hexahydrate.

[0046] In one embodiment of the present invention, in step (1), the volu...

Embodiment 1

[0063] This embodiment provides a method for preparing ultrathin ZIF-67 nanosheets at room temperature.

[0064] (1) At room temperature, 4mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in a mixed solvent composed of absolute ethanol and N,N-dimethylformamide with a volume ratio of 1:1 (each 60ml), and kept stirring for 10 minutes under the condition of a magnetic stirring speed of 500rpm / min. Homogenize to obtain cobalt nitrate solution.

[0065] (2) At room temperature, dissolve 16mmol dimethylimidazole in a mixed solvent composed of absolute ethanol and N,N-dimethylformamide with a volume ratio of 1:1 (60ml each), and stir at a magnetic stirring speed of 500rpm Under the condition of / min, the stirring was continued for 10 minutes, and the dimethylimidazole solution was obtained after mixing.

[0066] (3) The cobalt nitrate solution obtained in step (1) is quickly added to the dimethylimidazole solution obtained in step (2) to react, and the magnetic stirring speed is accelerat...

Embodiment 2

[0071] This embodiment provides a method for preparing ultrathin ZIF-67 nanosheets at room temperature.

[0072] (1) At room temperature, 4mmol CoCl 2 ·6H 2 O was dissolved in a mixed solvent composed of absolute ethanol and N,N-dimethylformamide with a volume ratio of 1:1 (each 60ml), and kept stirring for 10 minutes under the condition of a magnetic stirring speed of 500rpm / min. Obtain cobalt chloride solution after homogenization.

[0073] (2) At room temperature, dissolve 16mmol dimethylimidazole in a mixed solvent composed of absolute ethanol and N,N-dimethylformamide with a volume ratio of 1:1 (60ml each), and stir at a magnetic stirring speed of 500rpm Under the condition of / min, the stirring was continued for 10 minutes, and the dimethylimidazole solution was obtained after mixing.

[0074] (3) The cobalt chloride solution obtained in step (1) is quickly added to the dimethylimidazole solution obtained in step (2) to react, and the magnetic stirring speed is accele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com