Preparation method for silicon-carbon composite material

A technology of silicon-carbon composite materials and silicon powder, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, and electrolyte battery manufacturing, etc., can solve the problems of active material shedding, battery cycle stability decline, and structural collapse, etc., to improve electrical conductivity High performance, excellent cycle performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

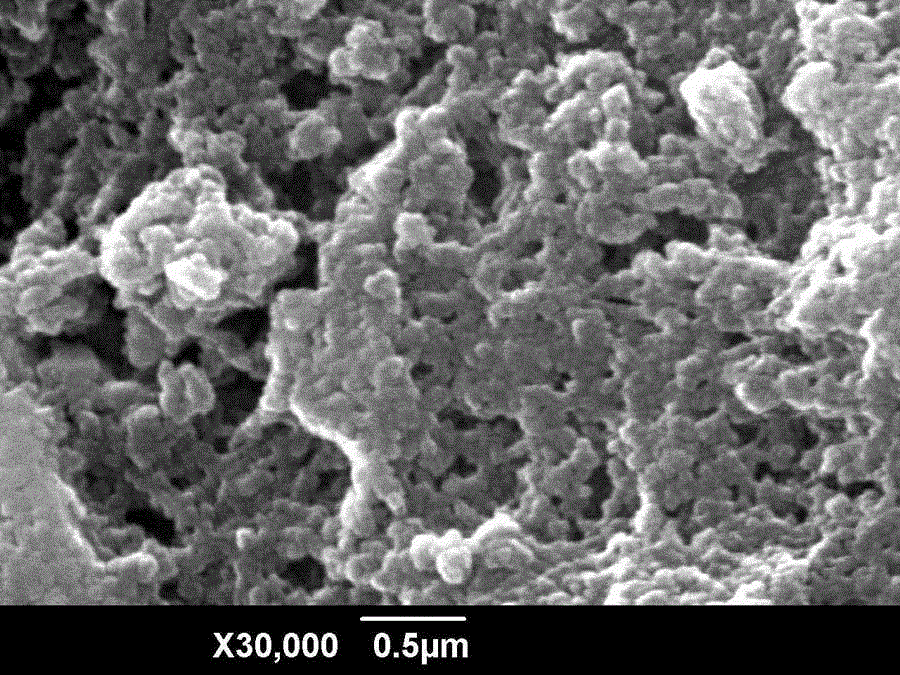

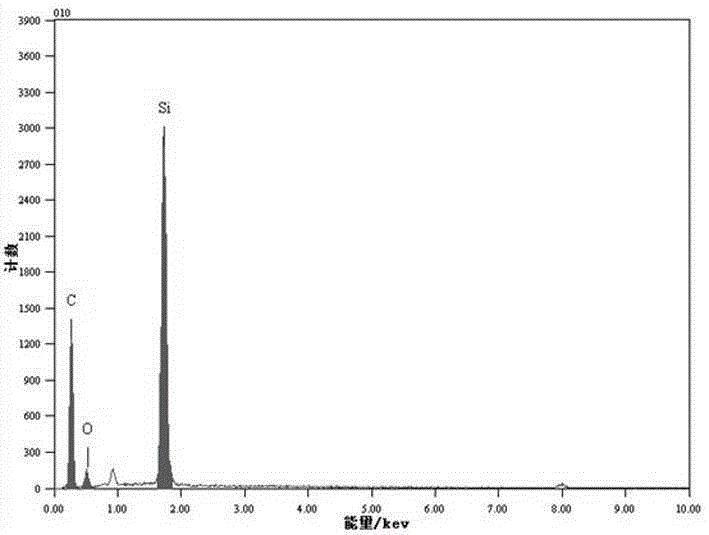

[0018] In a closed reactor, add 1g glucose, 0.1g polyvinylpyrrolidone (K30), 0.3g silicon powder and 3mL glacial acetic acid, and react at 200°C for 8 hours. After the reaction, a cylindrical gel is obtained. See figure 1 , the gel was freeze-dried and calcined at 1000° C. for 1 hour under a nitrogen atmosphere to obtain a silicon-carbon composite material. Its scanning electron microscope picture is shown in figure 2 , as can be seen from the figure, the composite material is spherical, with a size of about 100 nm; its EDX energy spectrum is shown in image 3 , It can be seen from the figure that the composite material contains three elements: carbon, oxygen and silicon.

Embodiment 2

[0020] In a closed reaction kettle, add 1g fructose, 0.1g polyacrylic acid, 0.1g silicon powder and 0.5mL formic acid, and react at 160°C for 8 hours. Calcined at 500° C. for 4 hours under a nitrogen atmosphere to obtain a silicon-carbon composite material.

Embodiment 3

[0022] In a closed reaction kettle, add 1g maltose, 0.1g polyacrylamide, 0.2g silicon powder and 3mL ethylene glycol, and react at 200°C for 8 hours. Calcined at 300° C. for 4 hours under a nitrogen atmosphere to obtain a silicon-carbon composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com