Crushing device for fresh kelp

A crushing device and kelp technology, applied in the direction of grain processing, etc., can solve the problems of aggravated clogging and adhesion, effective crushing of hard-to-fresh kelp, and easy adhesion, etc., and achieve the effects of reducing the number of shutdowns for cleaning, saving resources, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

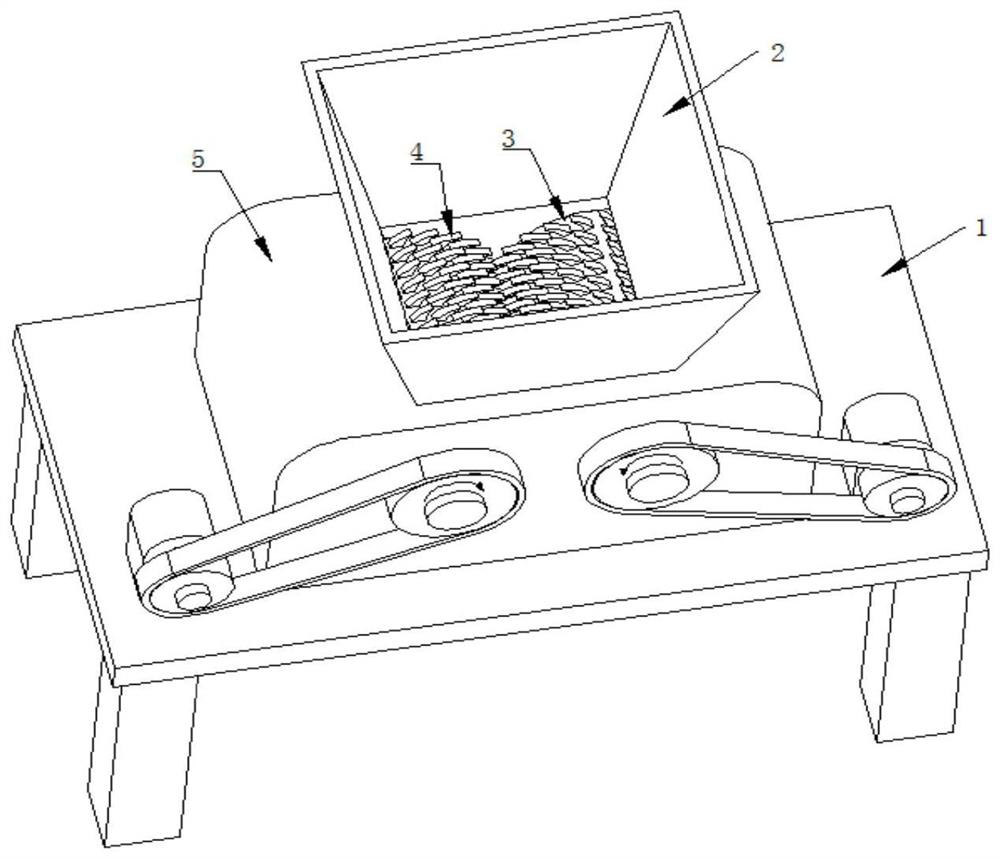

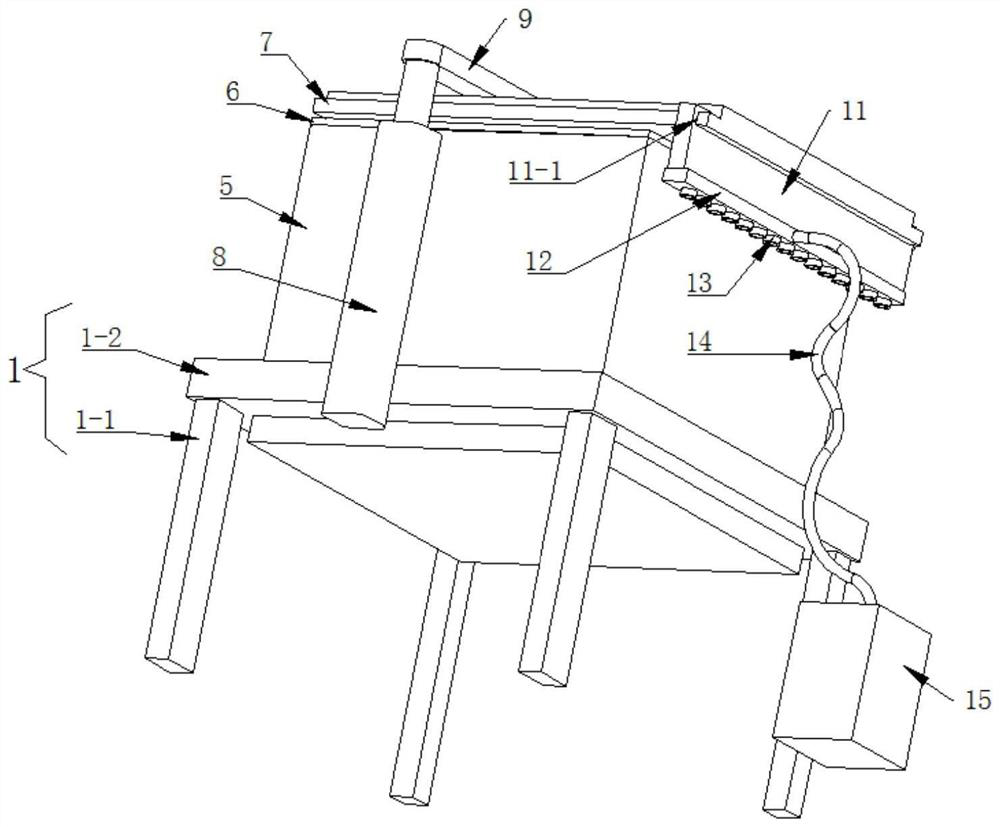

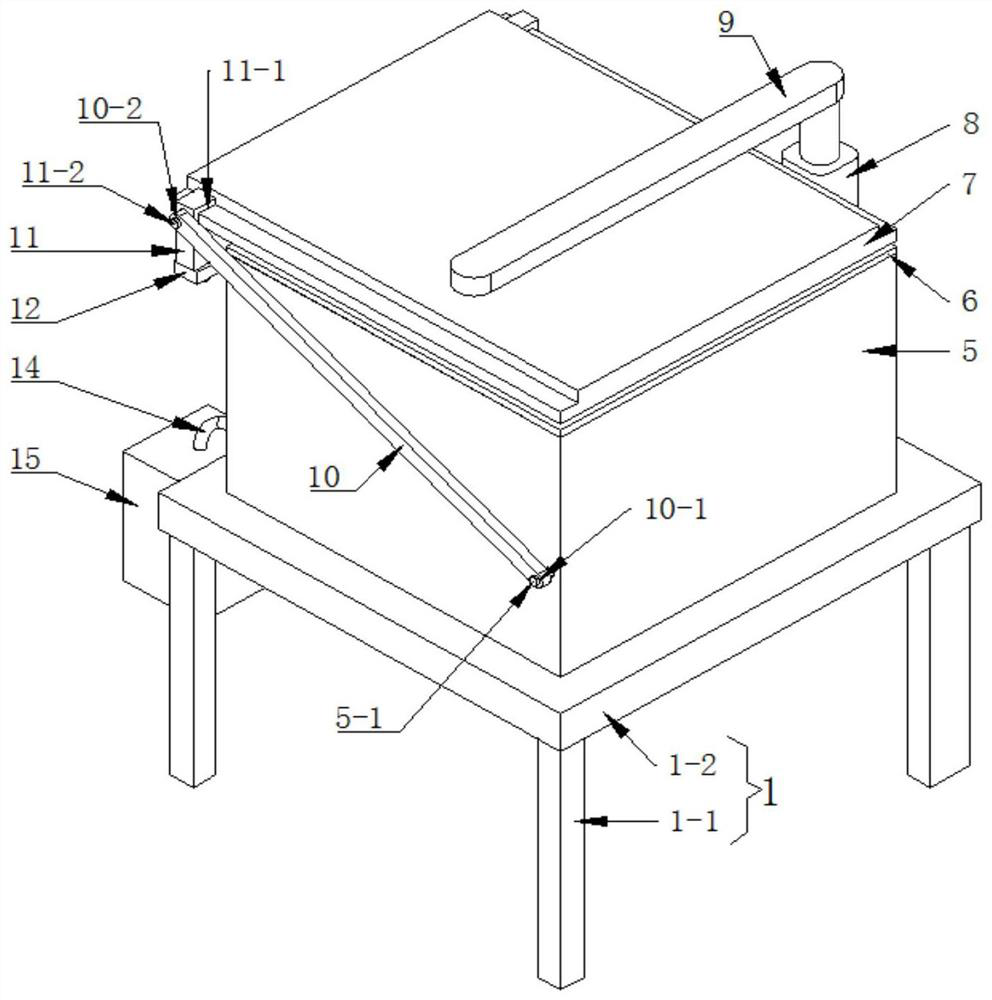

[0087] Such as figure 2 As shown, a fresh kelp crushing device includes a support 1 placed on the ground. The support 1 includes a support leg 1-1 and a support frame 1-2, and the upper end of the support leg 1-1 is welded to the support frame 1-2.

[0088] Such as figure 2 As shown, the collection box 5 is inserted into the inner ring of the support frame 1-2, the collection box 5 is fixed with the support frame 1-2 by screws, and the upper end surface of the collection box 5 is open. The upper end surface of the collection box 5 is fixed with a mesh plate 6 by screws, and the holes of the mesh plate 6 communicate with the inner cavity of the collection box 5 .

[0089] Such as figure 2 As shown, the top of the mesh plate 6 is provided with a pressing plate 7, and the pressing plate 7 is connected with the support 1 through a lifting mechanism, wherein the lifting mechanism includes an oil cylinder 8 and a depression bar 9, and the oil cylinder 8 is welded and fixed on t...

Embodiment 2

[0111] On the basis of embodiment 1, this embodiment 2 makes the following improvements:

[0112] Such as Figure 7 and Figure 8 As shown, in the fresh kelp crushing device of this embodiment, the lower end of the collecting box 5 is provided with a discharge port 5-2 and a shielding plate 16 for blocking the discharge port 5-2. The lower end of the box wall of the collection box 5 is provided with a long guide groove 5-3, and the long side of the long guide groove 5-3 is horizontally arranged, and the shield plate 16 is inserted in the long guide groove 5-3, and the shield plate 16 can be placed in the long guide groove 5-3. -Swipe in 3. In order to facilitate the grasping of the shielding plate 16, the end of the shielding plate 16 exposed to the collection box 5 is provided with a shielding grasping hole 16-1.

[0113] When the fresh kelp fragments collected in the collection box 5 need to be unloaded, the following operations need to be performed: (1) the staff will be...

Embodiment 3

[0116] In Embodiment 2, when opening the discharge port 5-2 of the collection box 5, the staff pulls the shielding plate 16 manually, relying on manpower, because the shielding plate 16 is full of fresh kelp fragments, so the shielding plate 16 is relatively heavy, so that pulling the shielding plate 16 needs to consume a lot of strength of the staff, so the labor intensity of the staff is increased.

[0117] For this, on the basis of embodiment 2, the present embodiment 3 makes the following improvements:

[0118] Such as Figure 9 As shown, in the fresh kelp crushing device of this embodiment, the baffle plate 16 includes a first baffle plate 16-2 and a second baffle plate 16-3 arranged side by side. Such as Figure 11 and Figure 13 As shown, the lower end surface of the collection box 5 is provided with a shielding dovetail groove 5-4, and the upper end surface of the first shielding plate 16-2 is welded with a first shielding slider 16-2-1, and the first shielding slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com