Double-row deep groove ball bearing inner ring outer raceway machining device and using method thereof

A deep groove ball bearing and processing device technology, applied in positioning devices, feeding devices, metal processing, etc., can solve the problems of increasing the purchase cost of manufacturers' equipment, easy left and right accidental shaking, and inconvenience of the inner ring of double row deep groove ball bearings, etc. Achieve the effect of reducing equipment procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

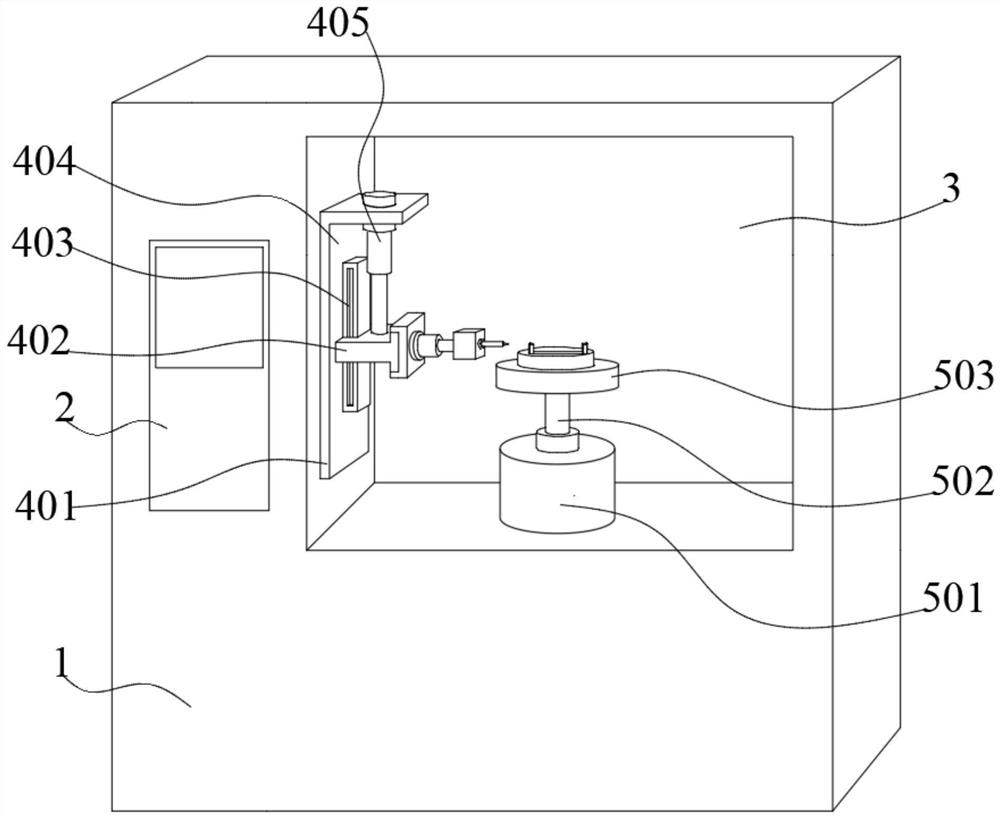

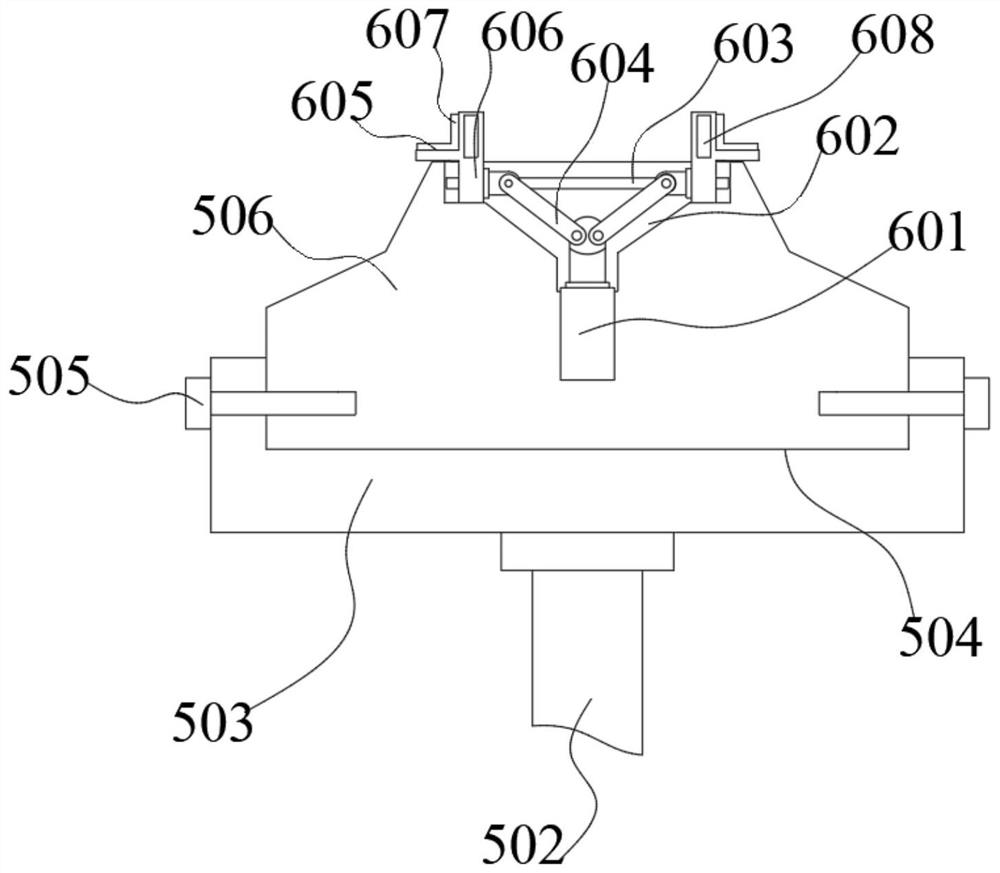

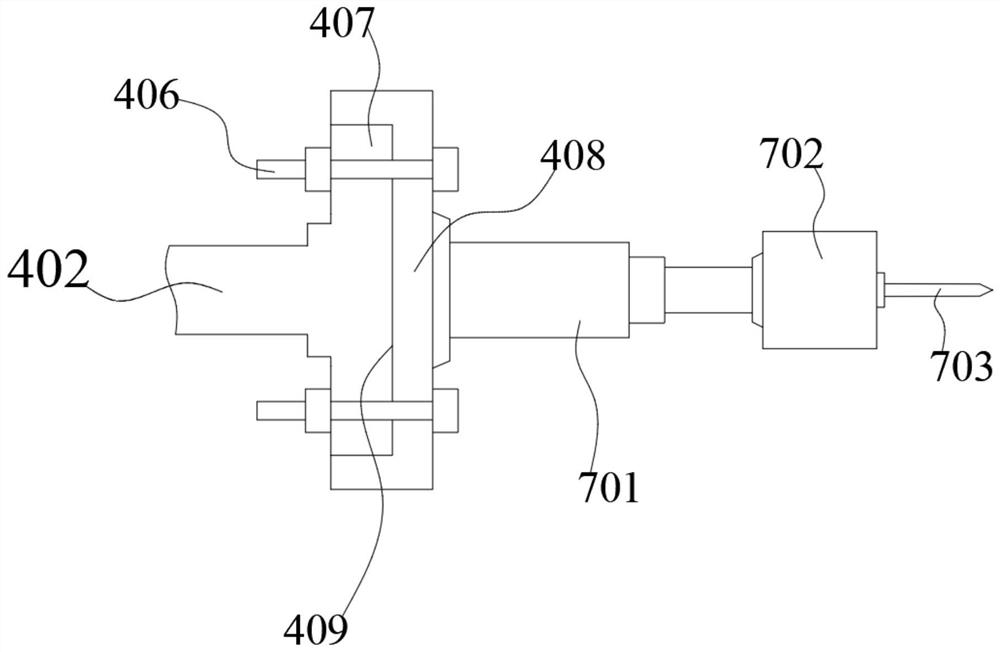

[0032] Such as Figure 1-5 As shown, a double-row deep groove ball bearing inner ring outer raceway processing device and its use method include a base 1, an adjustment mechanism, a steering mechanism, a clamping mechanism and a milling mechanism, and a controller is provided on the outer surface of the base 1 2, and the outer surface of the base 1 is provided with a processing groove 3 with the opening end forward, the left inner wall of the processing groove 3 is fixedly connected with an adjustment mechanism, and the adjustment mechanism is detachably connected with a cutting mechanism, and the processing groove 3. A steering mechanism is installed on the inner wall of the bottom surface, and the upper surface of the steering mechanism is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com