A Modular Cycloidal Propeller Using a Gear Synchronous Kite Mechanism

A cycloid propulsion, synchronous technology, applied in the field of power devices, can solve the problems of increasing the number of stepping motors, difficult blade precise control, inability to adjust the eccentric distance, etc., to achieve high revolution speed, small friction, easy to achieve Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings. This embodiment is only used to explain the present invention, and does not constitute a limitation to the protection scope of the present invention.

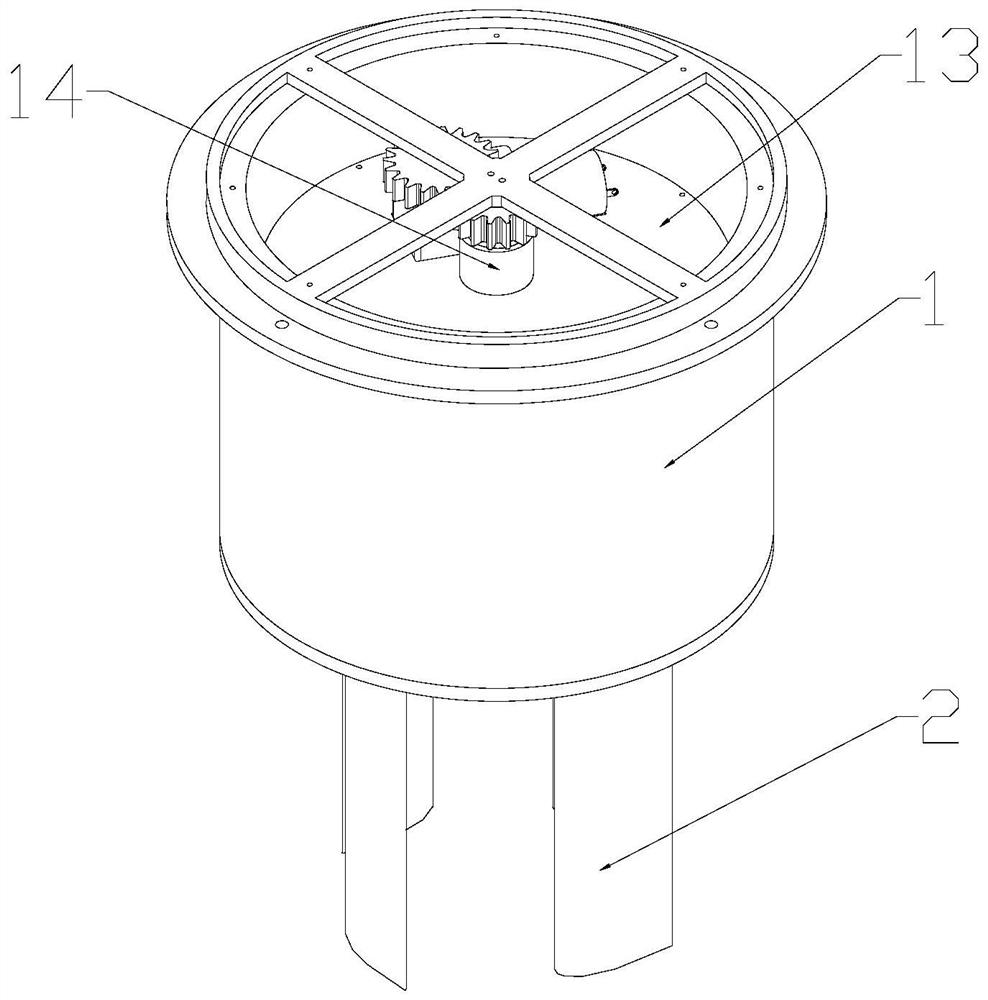

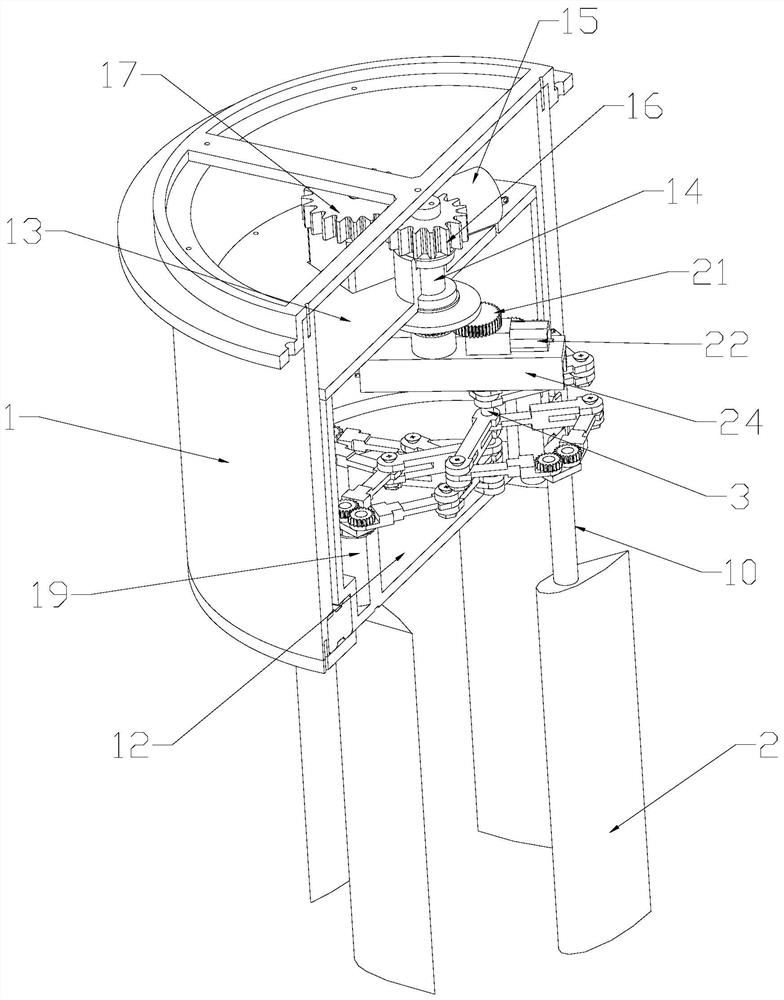

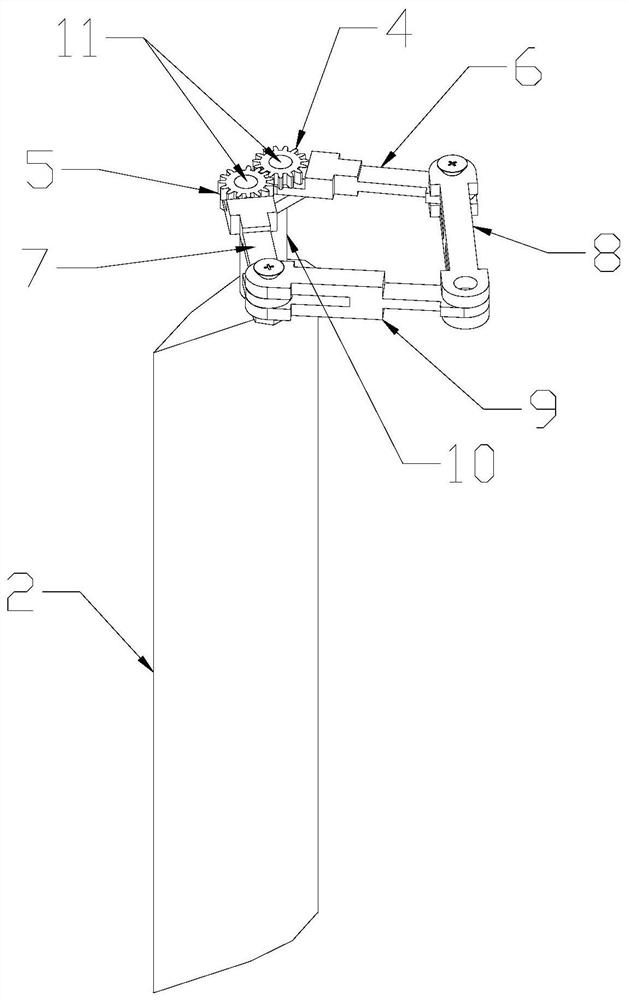

[0024] As a specific embodiment of the present invention, Figure 1-7 It shows a modular cycloidal propeller adopting a gear synchronous kite mechanism, including a driving mechanism, a casing 1, and a blade 2. The driving mechanism is arranged in the casing 1, and the blade 2 is connected to the driving mechanism. The driving mechanism can drive The blade 2 revolves around the center of rotation, and also includes a gear-synchronized kite mechanism and a control shaft 3 for controlling the rotation of the blade 2, such as image 3 As shown, the gear synchronous kite mechanism includes a first gear 4, a second gear 5, a first connecting rod 6, a second connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com