Textile cloth cutting device

A cutting device and textile cloth technology, which is applied in textiles and papermaking, textile material cutting, metal processing, etc., can solve the problems of textile cloth fixing and inconvenience, and achieve the effect of good fixation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

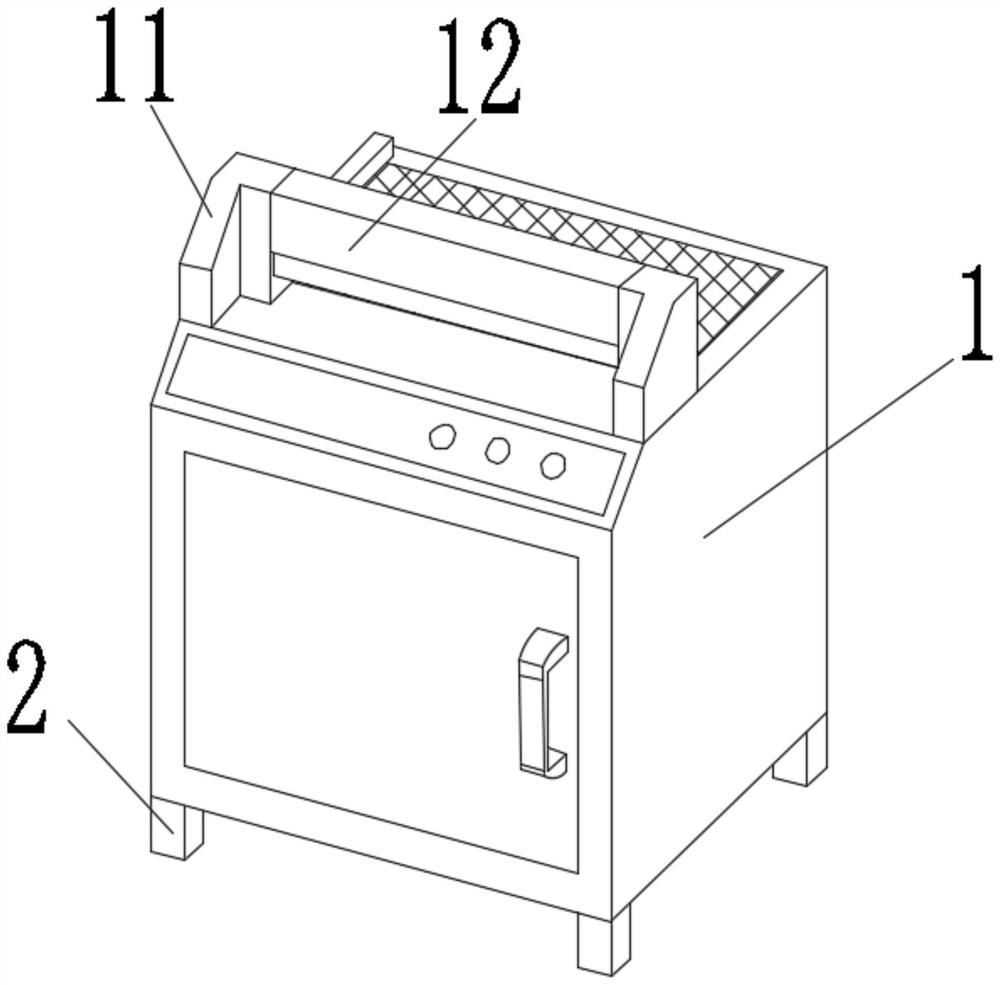

[0023] see Figure 1-5 ,

[0024] The present invention provides a technical solution: a textile cloth cutting device, comprising a box body 1, a limit block 11 is fixedly installed on the left and right ends of the top of the box body 1, and a cutting mechanism 12 is provided at the ends of the two limit blocks 11 that are close to each other. The front of the cabinet 1 is hinged with a single door;

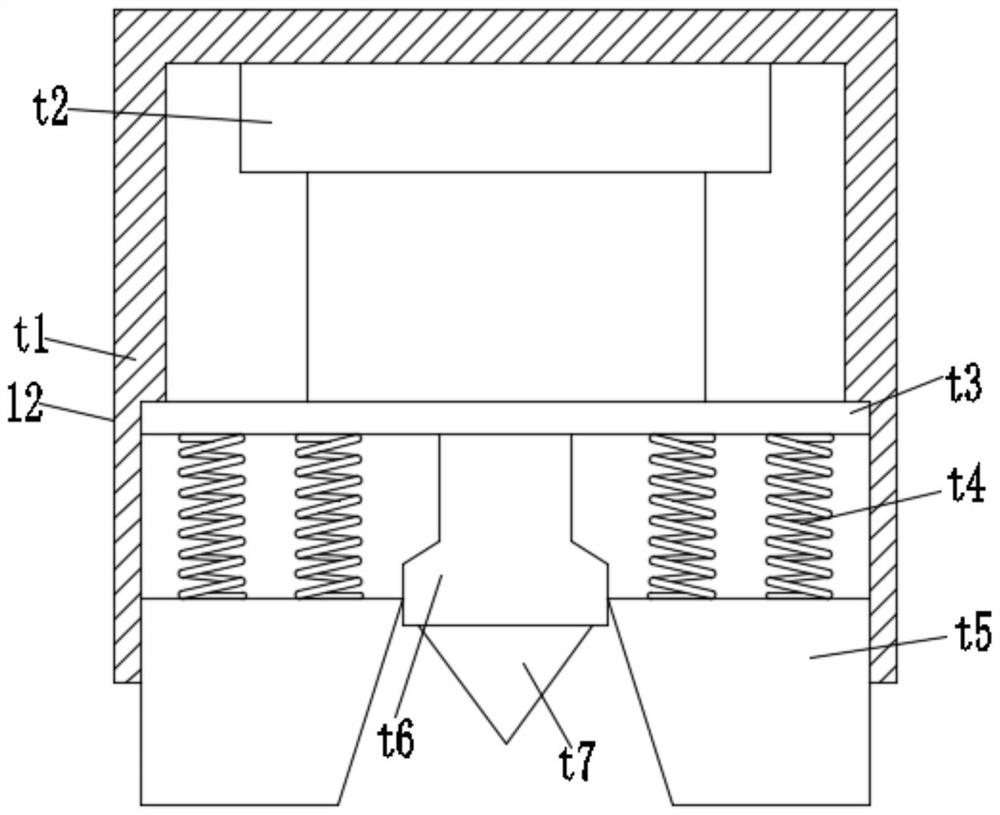

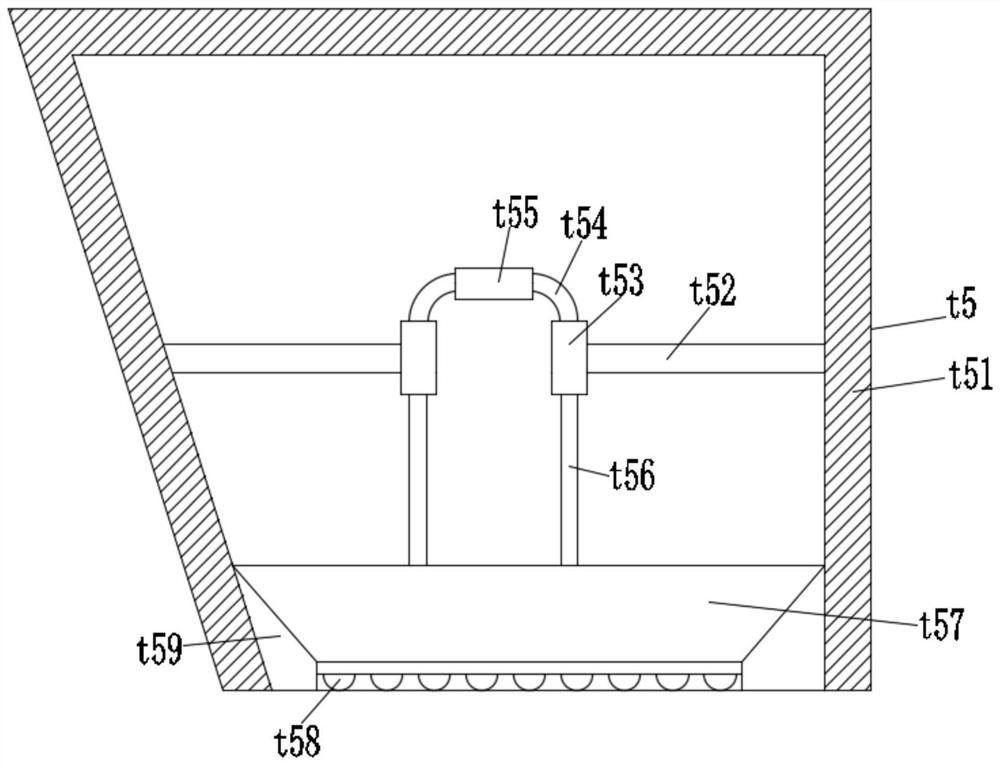

[0025] The inside of the cutting mechanism 12 includes a fixed block t1, a hydraulic cylinder t2, a connecting plate t3, a spring t4, a fixing device t5, a supporting block t6 and a cutting device t7. 11 The ends close to each other are fixedly connected, the hydraulic cylinder t2 is fixedly connected to the middle axis of the inner wall top of the fixed block t1, the connecting plate t3 is fixedly connected to the bottom of the hydraulic cylinder t3, the number of springs t4 is four, and the four springs t4 are fixedly connected respectively At the left and right ends of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap