Quick road surface garbage sweeper

A technology for cleaning vehicles and garbage, which is applied in the field of sanitation and cleaning equipment, and can solve the problems of high power energy consumption, low efficiency and unsatisfactory manual cleaning of garbage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

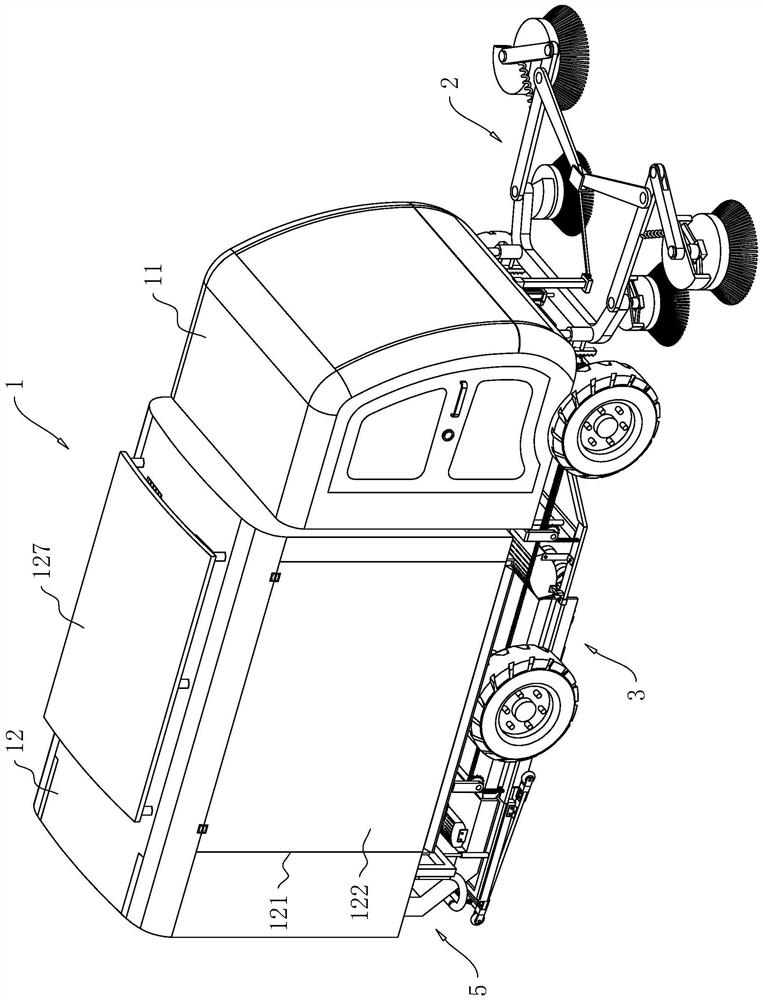

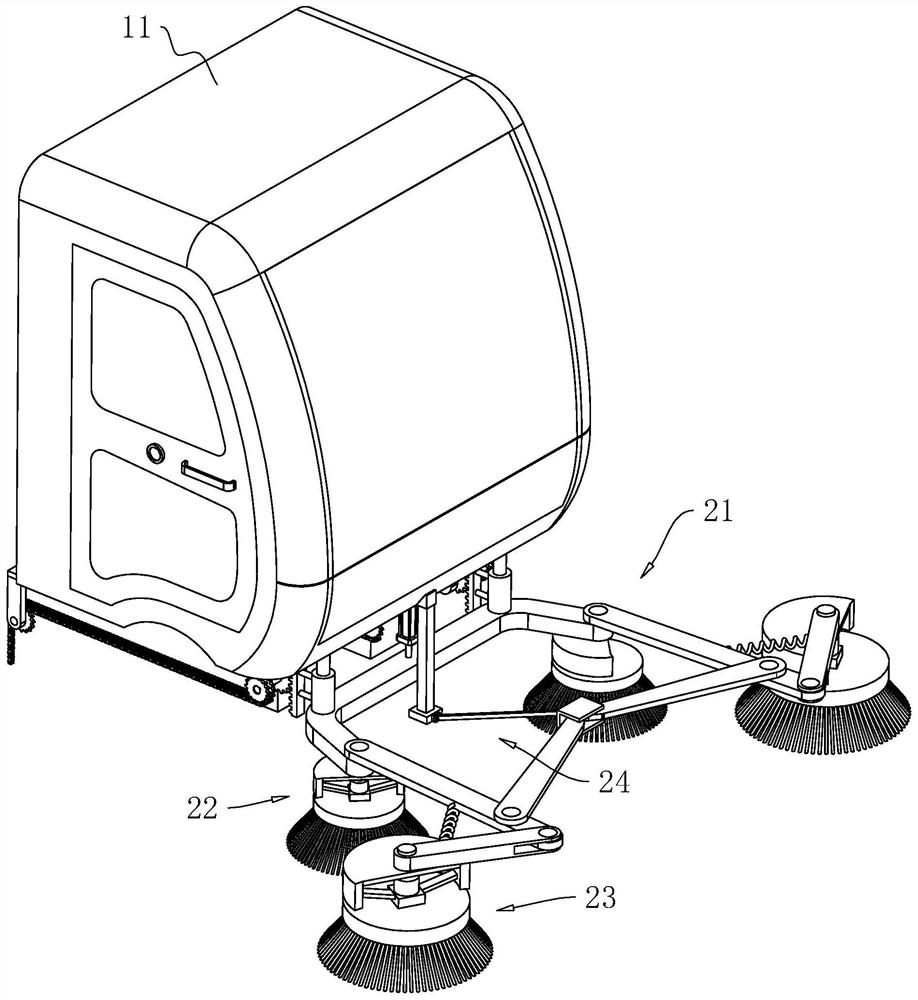

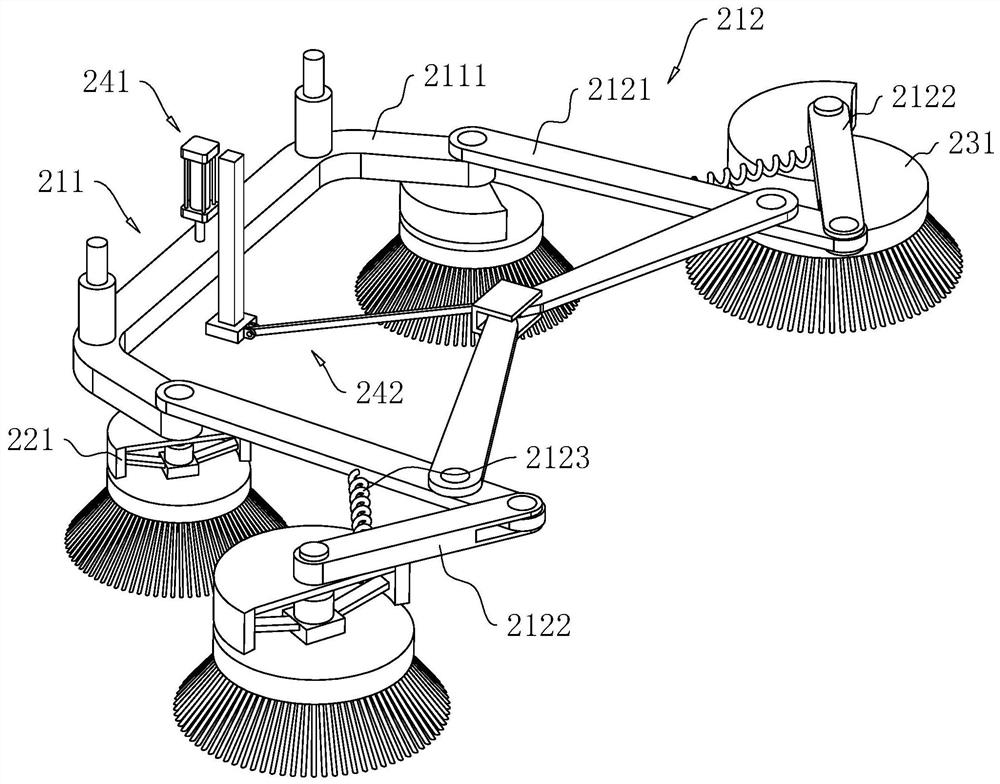

[0128] refer to figure 1 The road garbage quick sweeper includes a sweeper body 1, the sweeper body 1 includes a headstock 11 and a carriage 12, a garbage cleaning device 2 is arranged under the headstock 11, a garbage collection device 3 is arranged under the carriage 12, and a garbage collection device 3 is arranged at the rear of the carriage 12 Garbage conveyor 5. A garbage outlet 121 is provided on the side wall of the compartment 12, and a door panel 122 is provided at the garbage outlet 121 position.

[0129] During the running of the cleaning vehicle body 1, the garbage cleaning device 2 can clean the garbage on the road surface, and the garbage collection device 3 can collect the garbage on the road surface at the same time, and the garbage with light weight can enter through the garbage conveying device 5. In the compartment 12, when the garbage in the compartment 12 needs to be processed, the door panel 122 can be opened, and the garbage is discharged from the garb...

Embodiment 2

[0175] A kind of road rubbish fast cleaning vehicle, with reference to Figure 16 , the difference from Embodiment 1 is that an auxiliary conveying assembly 53 is provided in the conveying air duct 51 , mainly to make the garbage transport in the conveying air duct 51 more smoothly.

[0176] refer to Figure 17 with Figure 18 The end of the first horizontal section 511 is fixedly connected with two first extension plates 537 extending outwards parallel to each other. The auxiliary conveying assembly 53 includes an active shaft 531 arranged between two first extension plates 537, the active shaft 531 is rotatably connected to the two first extension plates 537, and specifically, a driving motor can be fixed on one of the first extension plates 537 , the driving motor is linked with the driving shaft 531 through a reducer. Both ends of the driving shaft 531 are provided with driving sprockets 532 , and the driving sprockets 532 are coaxially fixed with the driving shaft 531 ...

Embodiment 3

[0184] A kind of road rubbish fast cleaning vehicle, with reference to Figure 20 , the difference from Embodiment 2 is that: the ends of the two second extension plates 538 facing the headstock 11 are rotatably connected with connecting rods 541, and the connecting rods 541 extend into the collecting air duct 31, and the driven rotating shaft 533 is rotatably arranged on the connecting rod 541. One end of the rod 541 faces the headstock 11 . The circulating chain 535 and the conveying rod 536 pass through the transition air duct 55 and extend into the collecting air duct 31 .

[0185] The conveying rod 536 and the raking member 5361 can act on the garbage collected in the air duct 31, so that the garbage can quickly enter the conveying air duct 51 and be transferred to the compartment 12, which can ensure a fast and clean cleaning effect on the garbage.

[0186] refer to Figure 21 In order to prevent the connecting rod 541 from fitting the road surface through the garbage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com