Sealing strip, point supported glass curtain wall structure and point supported glass curtain wall

A technology for glass curtain walls and sealing strips, applied to walls, building components, building structures, etc., can solve problems such as stress concentration of glass panels, and achieve the effects of prolonging service life and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The embodiment of the present application provides a sealing strip, which is used to solve the technical problem that the stress of the glass panel of the existing point-supported glass curtain wall is too concentrated.

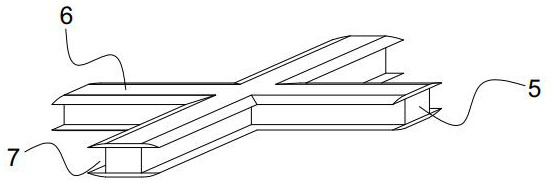

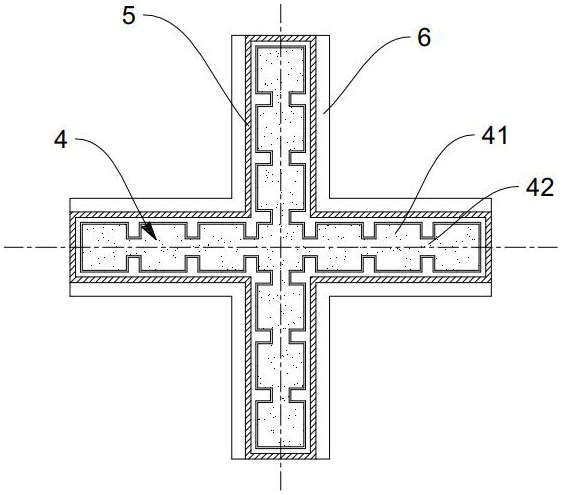

[0048] Such as figure 1 and figure 2 As shown, the sealing strip provided in this embodiment includes an airbag 4 , a casing 5 and a fastener 6 . The airbag 4 is made of transparent PTFE material, and the shell 5 and the fastener 6 are made of transparent wear-resistant silicone material. The airbag 4 , the shell 5 and the fastener 6 all have good flexibility, and due to the structural connection among the three, deformations can be transmitted to each other.

[0049] The weather strip has four ends and is cross-shaped. The fasteners 6 are fixed on the front and rear sides of the housing 5 , so as to form a "╬"-shaped tank 7 together with the side walls of the housing 5 .

[0050] The air bag 4 is filled with a certain volume of air, and is encaps...

Embodiment 2

[0053] The embodiment of the present application provides a point-supported glass curtain wall structure, which is used to solve the technical problem of weak deformation resistance of the existing point-supported glass curtain wall due to excessive stress concentration.

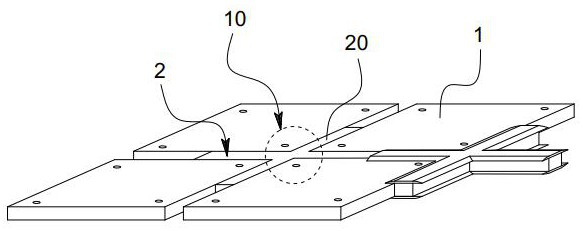

[0054] Such as image 3 As shown, the point-supported glass curtain wall structure provided in this embodiment includes several adjacent glass panels 1 and a fixing assembly for fixing the glass panels 1 . A sealing strip 2 is provided at the butt joint point 10 of the above-mentioned adjacent glass panels 1 . The sealing strip 2 adopts the structure provided in the first embodiment. The number of ends 20 of the sealing strip corresponds to the number of glass panels in the point-supported glass curtain wall structure, so that each end of the same sealing strip is sandwiched and fixed between two different adjacent glass panels, while ensuring the glass panels Each side edge joins with corresponding ends o...

Embodiment 3

[0056] The embodiment of the present application provides a point-supported glass curtain wall and its installation method, in order to obtain a glass curtain wall that can be flexibly designed with different heights and has strong deformation resistance.

[0057] Such as Figure 4 As shown, the glass curtain wall has the point-supported glass curtain wall structure provided in Embodiment 2. The figure shows a structural example of the corresponding sealing strip and its assembly when the number of glass panels in the point-supported glass curtain wall structure is 2, 3, and 4 respectively. Wherein, the right edge of the second glass panel 102, the fifth glass panel 105, and the lower edge and the right edge of the first glass panel 101 are closed by the closing structure 9 to form the edge of the glass curtain wall.

[0058] The first glass panel 101 , the second glass panel 102 , the third glass panel 103 , and the fourth glass panel 104 are movably fixed by the first conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com