Reinforced type subway prestressed beam body and manufacturing method thereof

A prestressed beam and reinforcement technology, which is applied in the field of concrete beams, can solve the problems of low strength of prestressed beams and uneven distribution of prestressed beams, and achieve the effects of improving the uniformity of distribution and reducing noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-5 The application is described in further detail.

[0040] The embodiment of the present application discloses a reinforced subway prestressed beam body.

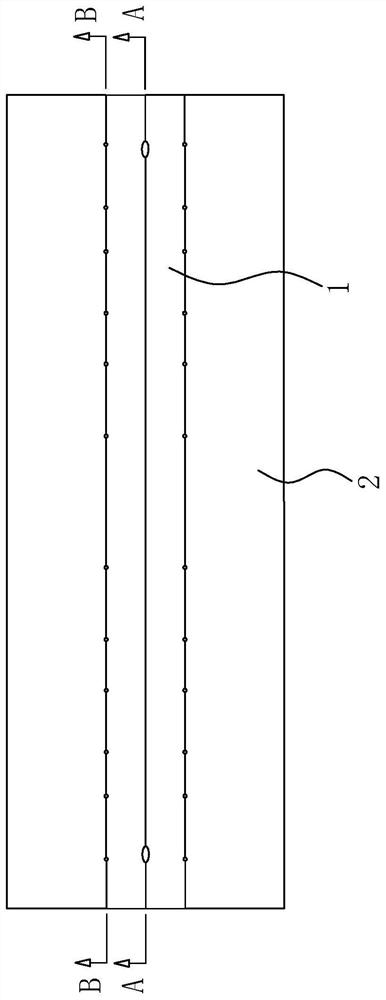

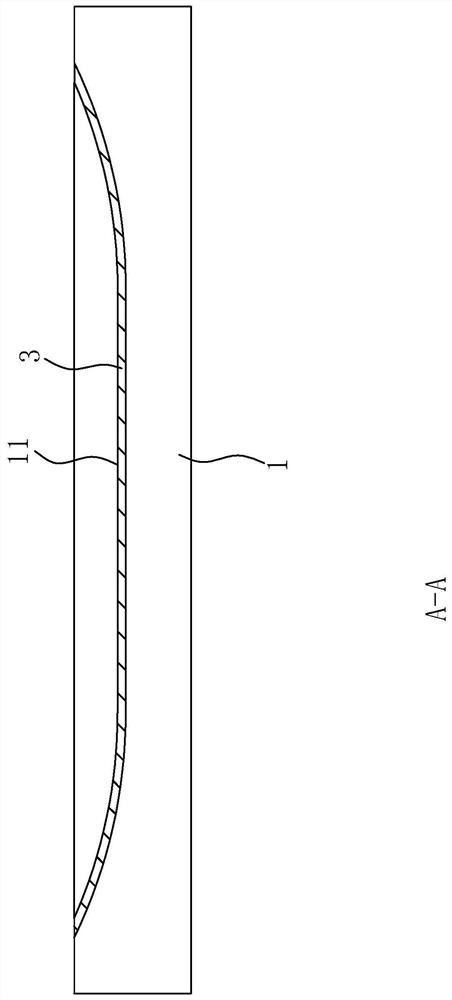

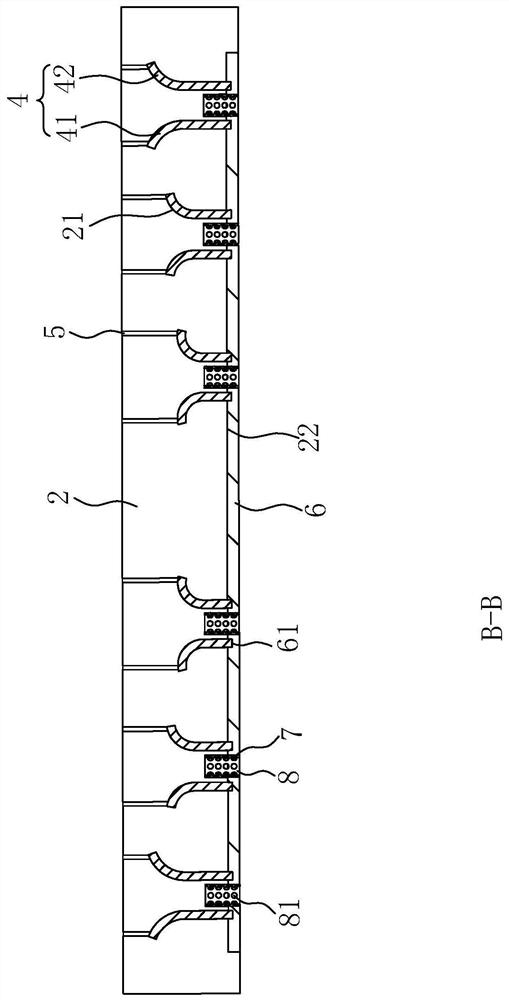

[0041] refer to figure 1 and figure 2 , the reinforced subway prestressed beam body includes a first concrete beam 1 and a second concrete beam 2, two first concrete beams 1 are oppositely arranged, the two first concrete beams 1 are fixed and attached to each other, and the two first concrete beams There are prestressed semi-channels on both sides of the 1 phase, and the two prestressed semi-channels are combined to form a curved prestressed channel 11 .

[0042] refer to figure 2 , the first prestressed tendon 3 is perforated in the prestressed channel 11, the length direction of the first prestressed tendon 3 is horizontally arranged, the bottom of the first prestressed tendon 3 protrudes downward, and the first prestressed tendon 3 is opposite to the first prestressed ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com