Electronic radiation crosslinking device of heat-resistant creep-resistant ultra-high molecular weight polyethylene fiber

An ultra-high molecular weight, polyethylene fiber technology, used in fiber processing, textiles and papermaking, physical processing and other directions, can solve the problems of tightness cannot be effectively guaranteed, damage, deformation, etc., to achieve the overall radiation crosslinking effect guarantee, Effects of improved distribution uniformity and improved binding tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

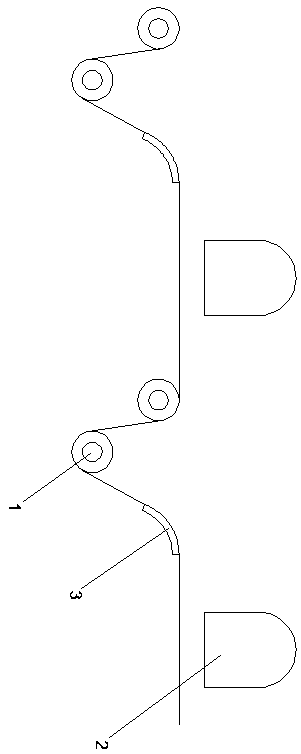

[0015] Such as figure 1 An electronic radiation crosslinking device for heat-resistant and creep-resistant ultra-high molecular weight polyethylene fibers is shown, which includes multiple sets of transmission rollers 1, and electron radiation light sources arranged on any two adjacent transmission rollers 1 2; a spreading device is arranged between the electron radiation light source 2 and its adjacent transmission roller 1, and the spreading device includes a spreading plate 3 adopting an arc structure, which is placed between the ultra-high molecular weight polyethylene fiber Bend in the direction of transport.

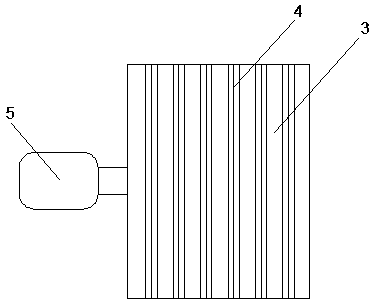

[0016] As an improvement of the present invention, such as figure 2 As shown, a plurality of spinning stripes 4 extending parallel to each other are arranged on the spinning board 3 , and each spinning stripe 4 extends parallel to the extending direction of the spinning board; the height of each spinning stripe 4 is is 3mm. By adopting the above technical solut...

Embodiment 2

[0019] As an improvement of the present invention, the width of any position of the spreading stripes 4 is gradually reduced in the direction where the end surface connected to the spreading plate 3 extends toward its upper end, and the side ends of the spreading stripes 4 adopt a direction of The 3 sides of the spinning plate are curved in an arc-shaped structure.

[0020] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0022] As an improvement of the present invention, the spinning device includes a vibrating motor 5 provided at the side end of the spinning plate. By adopting the above-mentioned technical solution, the whole spinning board can be vibrated within a certain range, so that the polyethylene fiber can be affected by the vibration on the spinning board to further improve its distribution uniformity.

[0023] The remaining features and advantages of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com