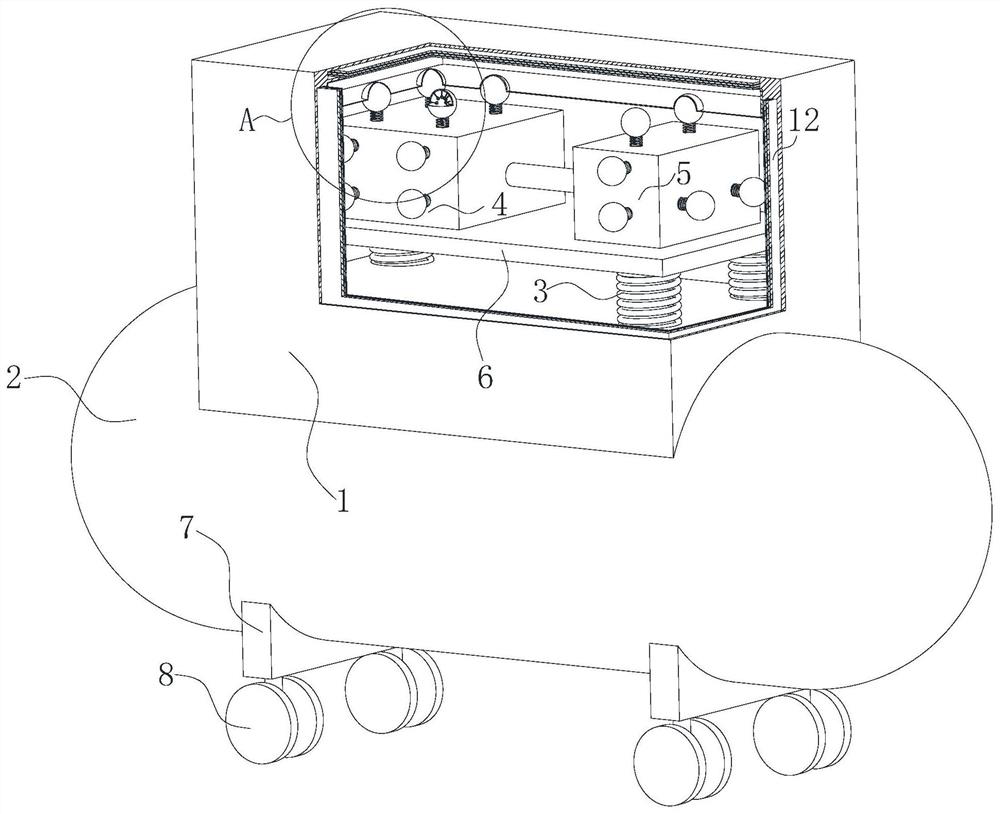

Gas compressor

A gas compressor and airbag technology, applied in the field of gas compressors, can solve the problems of insignificant shock absorption effect and high-frequency noise of the compressor, and achieve the effects of increasing the number of collisions, reducing shaking, and speeding up the recovery of calm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

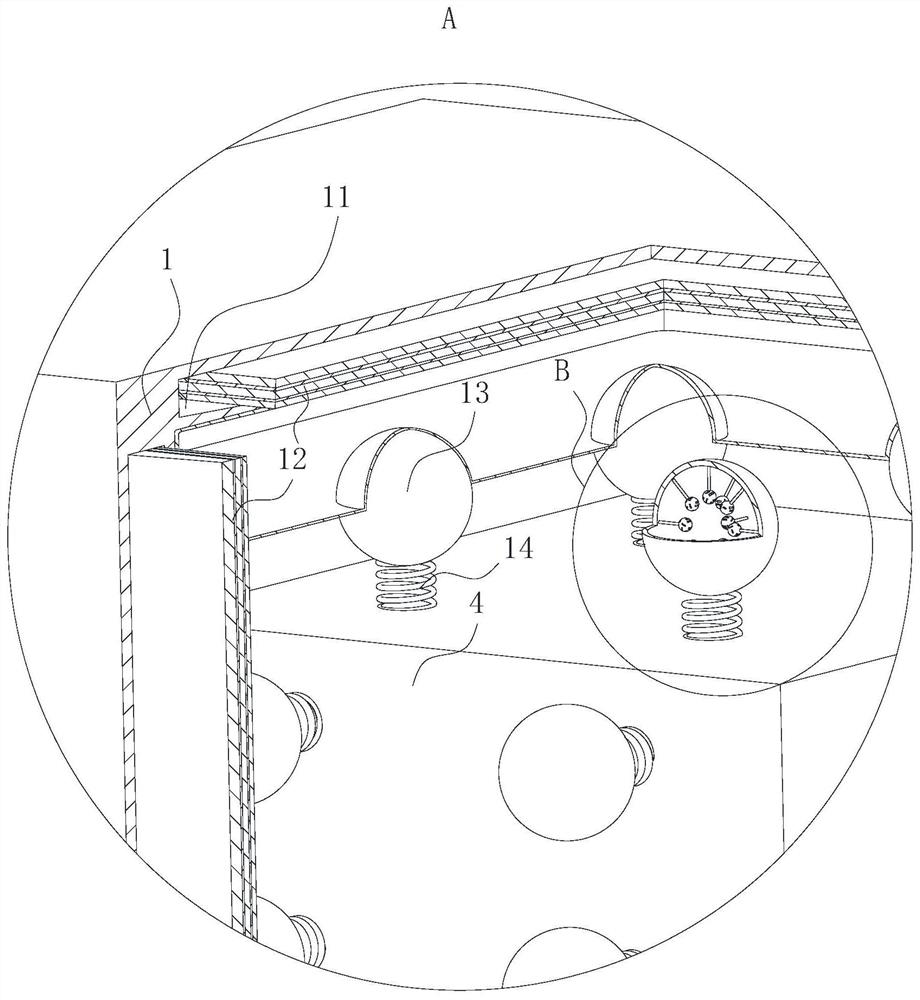

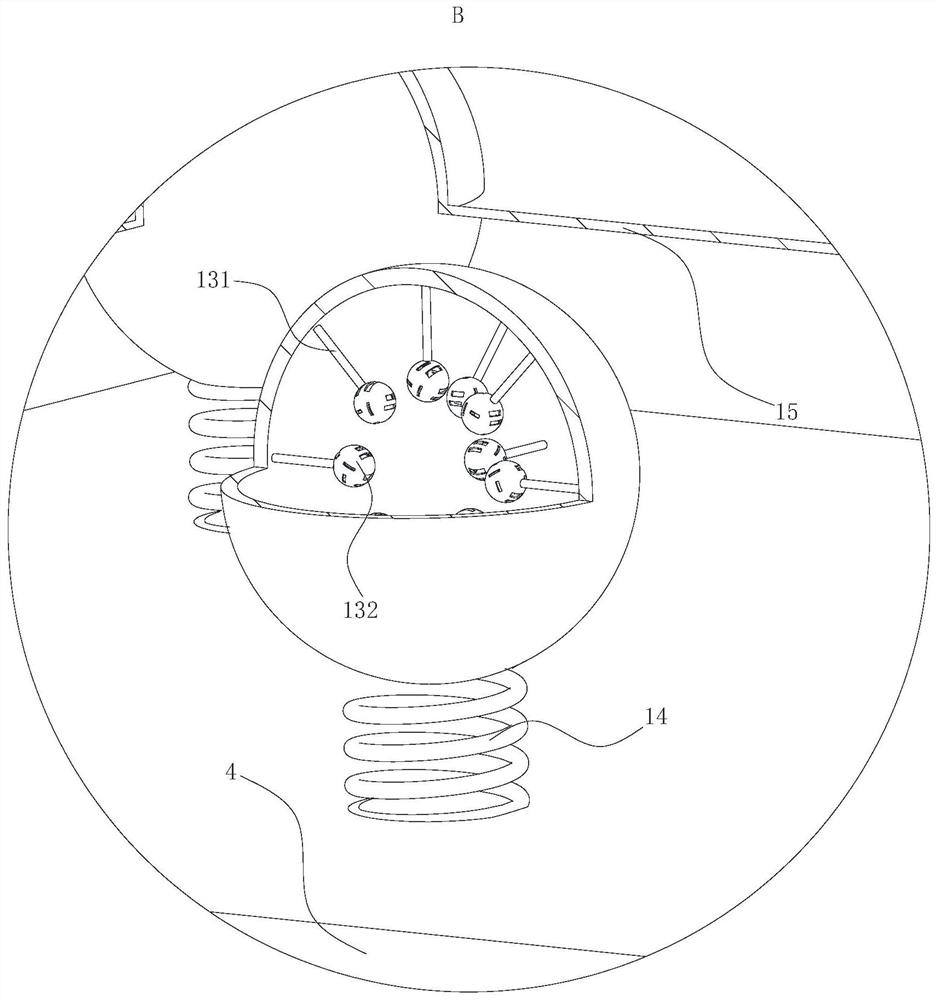

[0031] As an embodiment of the present invention, resistance rods 131 are fixedly installed on the inner surface of the mass ball 13; the resistance rods 131 are evenly distributed inside the mass ball 13; the resistance rods 131 are made of elastic materials, and the resistance rods 131 is cylindrical; the side of the resistance rod 131 away from the mass sphere 13 points to the center of the mass sphere 13 , and the resistance rod 131 is in contact with the buffer liquid in the mass sphere 13 .

[0032] When working, the vibration of the mass ball 13 causes the buffer liquid to shake irregularly. At the same time, resistance rods 131 are evenly distributed inside the mass ball 13. During the shaking of the buffer liquid, the buffer liquid collides with the resistance rods 131 inside the mass ball 13 , due to the elasticity of the resistance rod 131, buffering is performed when the buffer liquid impacts the resistance rod 131, so that the buffer liquid is relatively calm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com