Method for characterizing inclusions on section of stainless steel precision strip steel

A technology for stainless steel and inclusions, which is applied in the field of inclusion characterization of stainless steel precision strips, and can solve problems such as the inability to observe and characterize the morphology of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Sample preparation, process the stainless steel precision strip steel sample with a section thickness specification of 0.05 mm, and cut it into a long strip sample with a length of 25 mm and a width of 18 mm with scissors to meet the sample preparation requirements for inclusions ;

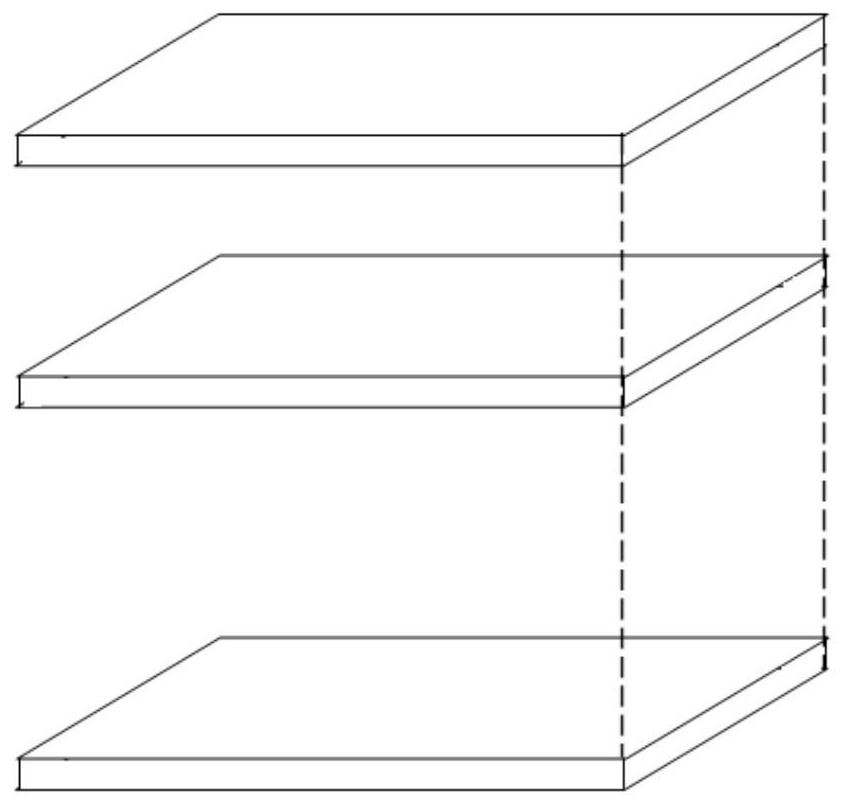

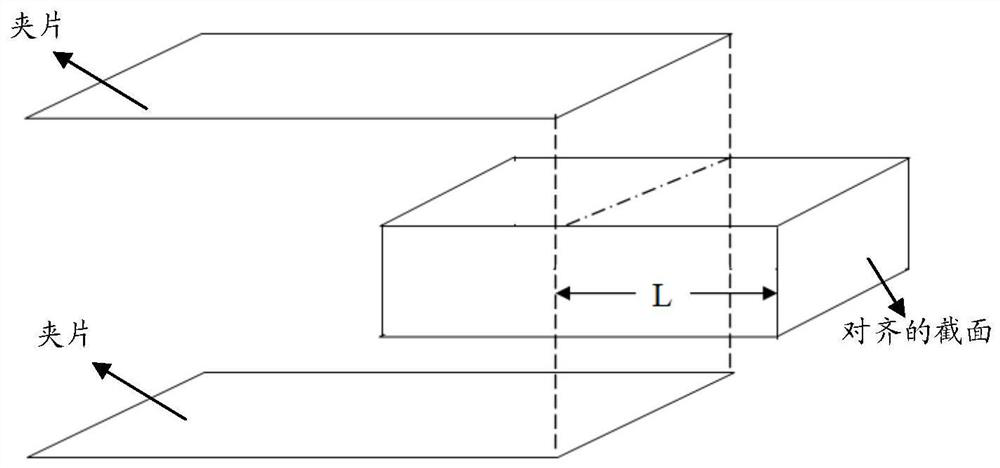

[0052] (2) Fix the sample, superimpose the processed 30 samples, align the cross-section of the sample with a length of 25 mm, put it into two stainless steel clips, and the aligned cross-section protrudes 1 mm from the end of the clip, and then Fasten the stainless steel clips with two pairs of screws and nuts to ensure that the aligned sections of the 30 samples are on one plane;

[0053] (3) Sample polishing, rough polishing, medium polishing, and fine polishing of the fixed sample section to achieve a mirror effect, cleaning and drying, to meet the analysis and detection requirements for inclusions;

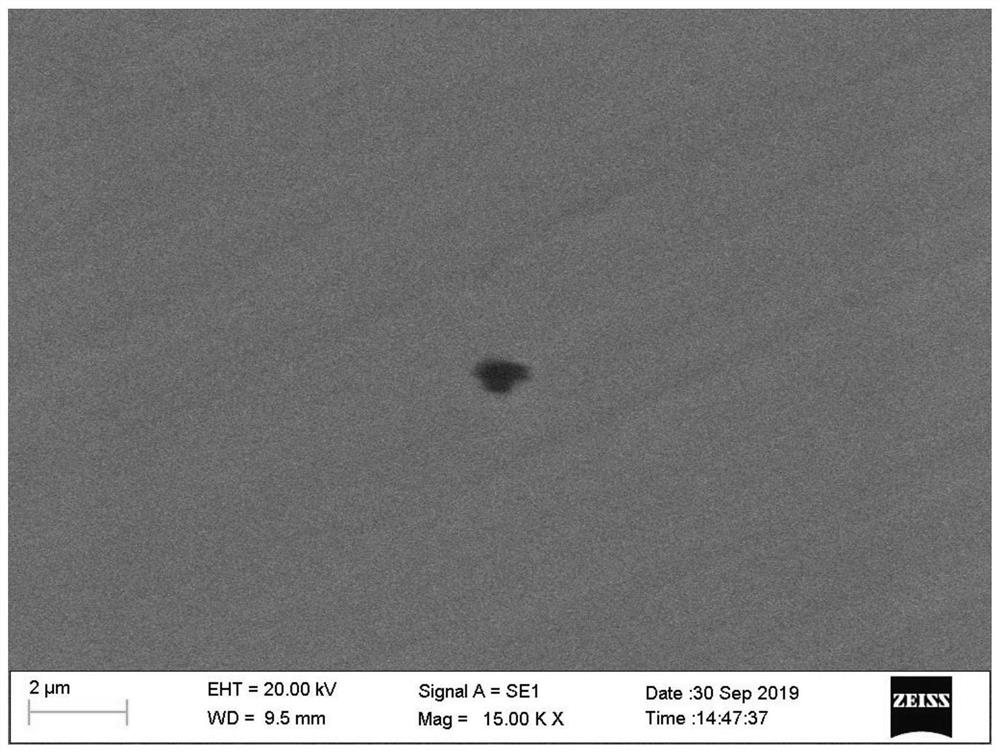

[0054] (4) Analysis and detection, put the discarded sample into the EVO18 scanni...

Embodiment 2

[0056] (1) Sample preparation, process the stainless steel precision strip steel sample with a section thickness specification of 0.02 mm, and cut it into a long strip sample with a length of 30 mm and a width of 20 mm with scissors to meet the sample preparation requirements for inclusions ;

[0057] (2) Fix the sample, superimpose the processed 50 samples, align the section of the sample on the side with a length of 30mm, put it into two stainless steel clips, and the aligned section protrudes 1mm from the end of the clip, and then Fasten the stainless steel clips with two pairs of screws and nuts to ensure that the aligned sections of the 50 samples are on one plane;

[0058] (3) Sample polishing, rough polishing, medium polishing, and fine polishing of the fixed sample section to achieve a mirror effect, cleaning and drying, to meet the analysis and detection requirements for inclusions;

[0059] (4) Analysis and detection, put the discarded sample into the EVO18 scanning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com