LF furnace electrode test system and test method

A test system and test method technology, applied in the field of refining, can solve problems such as waste of production resources and difficult adjustment, and achieve the effects of reducing debugging time, improving equipment stability, and reducing equipment debugging and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

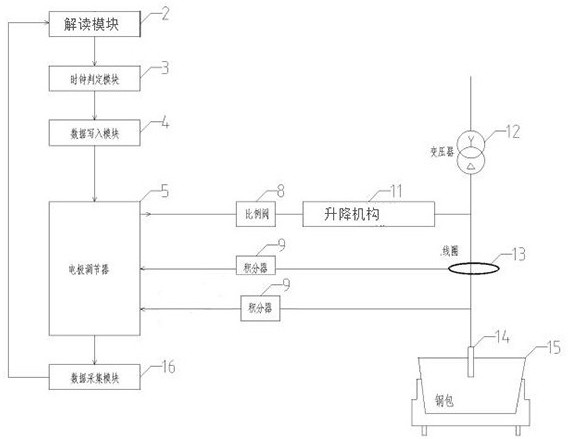

[0024] Such as figure 1 As shown, a LF furnace electrode testing system includes an electrode regulator 5, a lifting mechanism 11, an electrode 14, a coil 13 and a controller. The electrode 14 is connected to the lifting mechanism 11, and the electrode 14 passes through the coil 13, and the coil 13 is also electrically connected to a first feedback module, and the electrode 14 is also electrically connected to a second feedback module, both the first feedback module and the second feedback module are connected to the electrode regulator 5 with electrical signals, and the controller is connected to the electrode regulator 5 with electrical signals .

[0025] Both the first feedback module and the second feedback module are integrators 9 .

[0026] The electrode regulator 5 is also electrically connected with a proportional valve 8 , and the proportional valve 8 is connected with the lifting mechanism 11 .

[0027] The controller includes a data collection module 16, an interp...

Embodiment 2

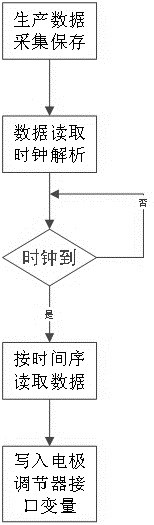

[0033] On the basis of Example 1, such as figure 1 with figure 2 Shown, a kind of LF furnace electrode testing system test method, comprises the following steps

[0034] Historical data input, input the historical data collected in the actual production into the controller,

[0035] Historical data reading, the controller reads the data value at a certain moment in the historical data, and transmits it to the electrode regulator 5, and the electrode regulator 5 determines the position of the electrode 14, and the controller sends a signal to the lifting mechanism 11 according to the position of the electrode 14, Drive the lifting mechanism 11 to move, so that the electrode 14 moves to a designated position;

[0036] Position feedback, the first feedback module and the second feedback module return the real-time measured data to the electrode regulator 5, and the electrode regulator 5 determines the designated position of the electrode 14 according to the actual data. If the...

Embodiment 3

[0047] On the basis of Example 2, such as figure 1 with figure 2As shown, the collected historical data is input into the interpretation module 2, and the interpretation module 2 converts the historical data into a format readable by the electrode regulator 5, and then inputs it to the electrode regulator 5.

[0048] The historical data includes arc current and arc voltage, and the time corresponding to the arc current and arc voltage.

[0049] In the cyclic test stage, the clock judging module 3 performs a cyclic timing trigger to judge whether the test time increment reaches the clock value, if so, reads new historical data, and transmits it to the data writing module 4, and the data writing module 4 Transfer to the electrode regulator 5, otherwise return to wait.

[0050] The data collection module 16 also collects and saves real-time data during actual operation.

[0051] The historical data is stored in the acquisition data module 16, and the interpretation module 2 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com