Photovoltaic panel snow cleaning and defrosting system

A technology for photovoltaic panels and snow shovels, applied in photovoltaic power generation, photovoltaic modules, cleaning methods and appliances, etc., can solve problems such as high labor costs, hidden safety hazards, and low efficiency, and achieve improved service life, clean and thorough defrosting, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

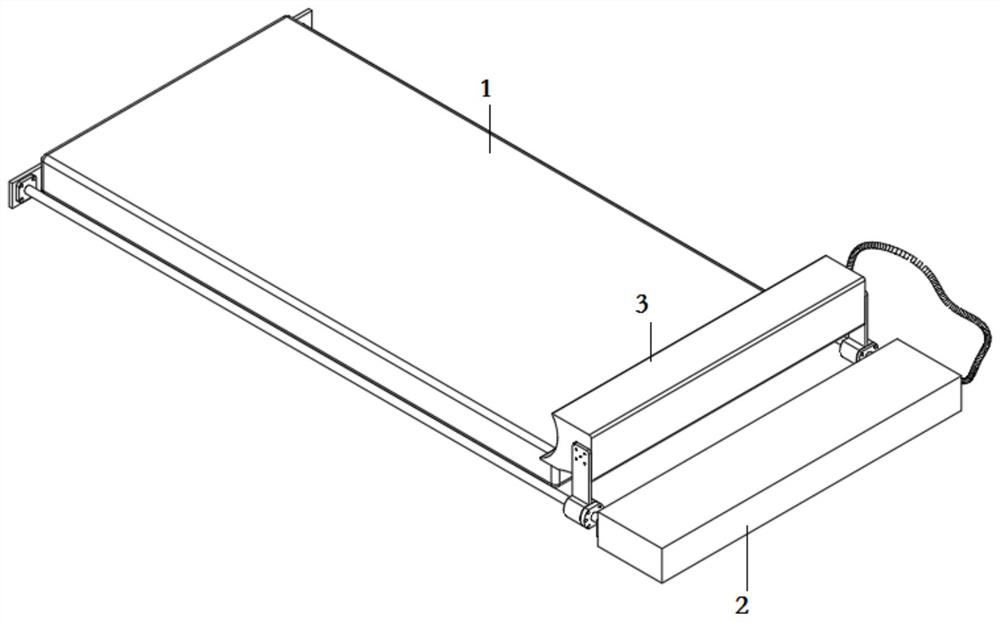

[0029] like Figure 1-3 As shown, the photovoltaic panel snow clearing and defrosting system of the present invention includes a photovoltaic panel body 1, a snow clearing mechanism 2 is arranged on one side of the photovoltaic panel body 1, and a defrosting mechanism 3 is arranged on the side of the photovoltaic panel body 1 close to the snow clearing mechanism 2 ;

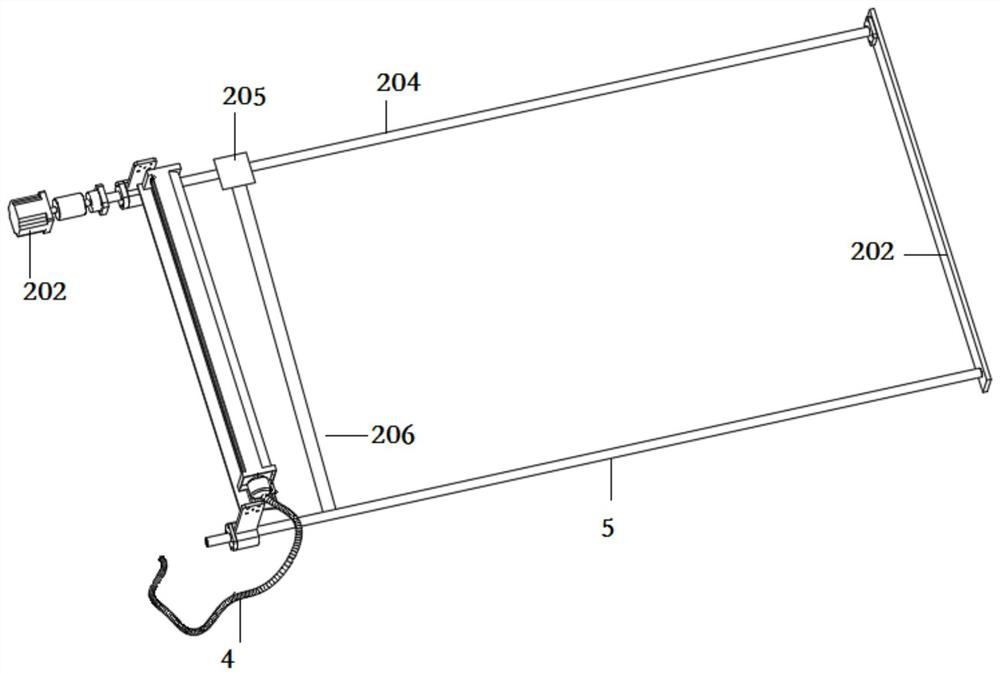

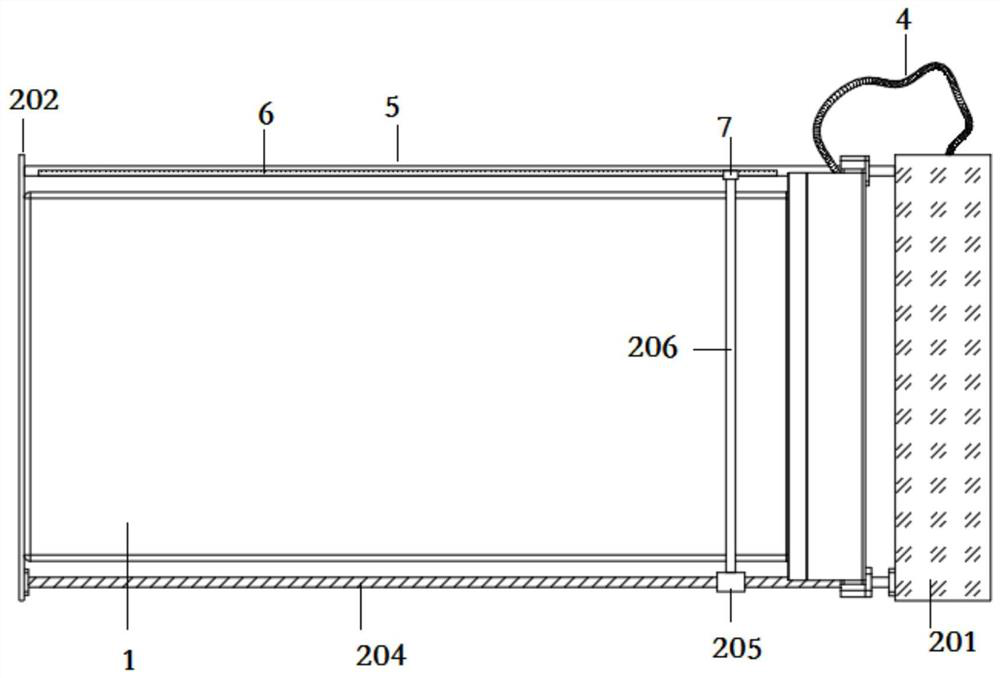

[0030] The snow clearing mechanism 2 includes a motor installation cover 201, the outer side wall of the motor installation cover 201 is fixed to one side of the photovoltaic panel body 1, and the side wall of the end of the photovoltaic panel body 1 away from the motor installation cover 201 is fixed with an abutment support plate 202, A servo motor 202 is installed in the inner cavity of the motor installation cover 201, and the output end of the servo motor 202 is sleeved with a rotating screw 204, and the outer wall of the rotating screw 204 is screwed with a snow-clearing sliding sleeve 205, which is close t...

Embodiment 2

[0033] Wherein, the defrosting mechanism 3 includes a fan installation cover 301, a defrosting blower 302 is installed in the inner cavity of the fan installation cover 301, a heater is installed in the snow clearing blade 206, and a battery and a controller are installed on the motor installation cover 201. , the defrosting blower 302, the servo motor 202, and the heater are respectively electrically connected to the battery through the wire 4, the controller is connected to the defrosting blower 302, the servo motor 202, and the pct heater signal, and the photovoltaic panel body 1 is far away from the rotating wire Bar 204 one end side walls are fixed with anti-rotation support plate 5, offer fixed chute 6 on the anti-rotation support plate 5, are fixed with the anti-rotation slider 7 that is slidably connected with fixed chute 6 on the snow clearing shovel plate 206, and the rotation wire The bar 204 is rotatably connected to the side wall of the support plate 202 by connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com