Sugarcane sectioning equipment

A cutting and equipment technology, applied in agricultural machinery and equipment, metal processing, energy-saving measures, etc., can solve the problems of low convenience, manpower consumption, and difficulty in improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

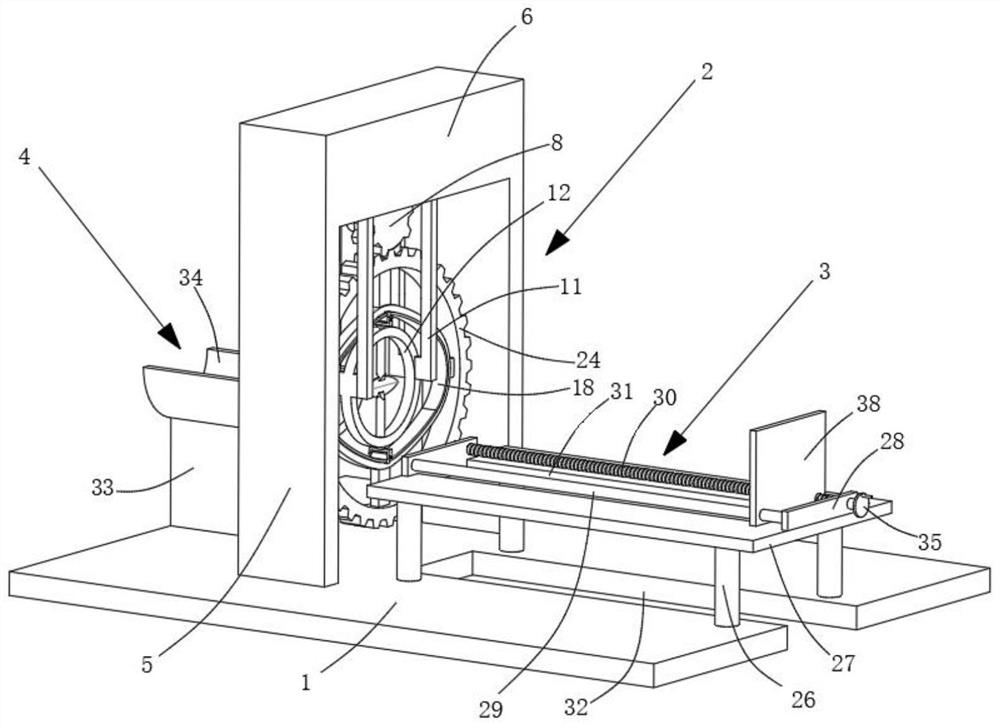

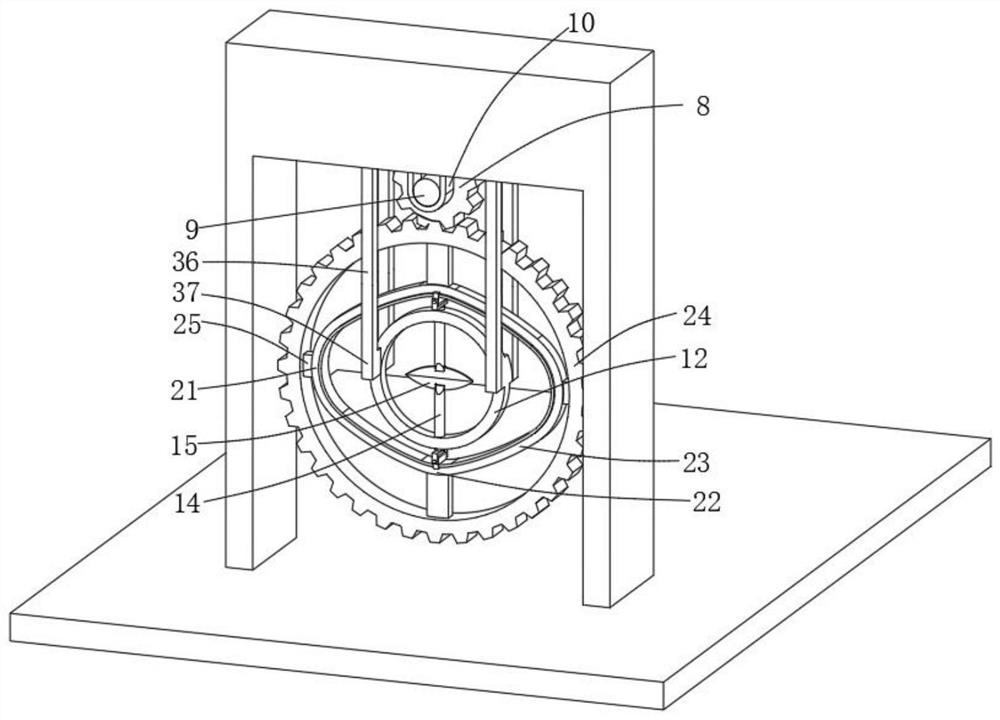

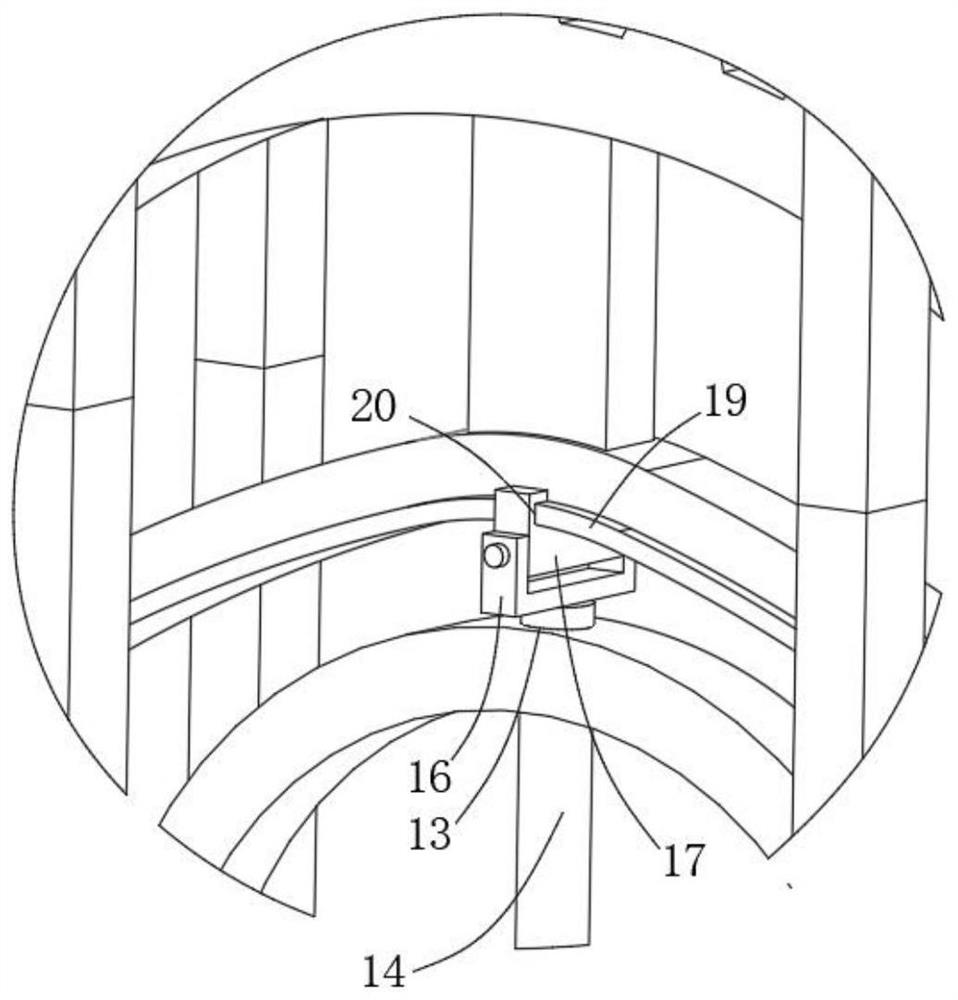

[0022] Embodiment: a kind of sugarcane cutting equipment, as attached figure 1 As shown, including a base 1, the base 1 is provided with a cutting mechanism 2, as attached figure 2 And attached Figure 4 As shown, the two sides of the cutting mechanism 2 are respectively provided with a length adjustment mechanism 3 and a supporting plate 4, and the cutting mechanism 2 includes a motor pole 5 symmetrically arranged on the base 1, and the ends of the motor pole 5 are jointly arranged There is a motor housing 6, and the motor housing 6 is provided with a rotating motor 7. The rotating motor 7 can flexibly adjust the rotating speed as required, so as to adjust the cutting speed of the sugarcane section. A transmission shaft 9 is provided at the center of the circle, and the transmission shaft 9 is connected with the output end of the rotating motor 7 by a transmission belt 10; An inner circular frame 12 is provided together, and the upper and lower parts of the inner circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com