Device and method for producing concrete member

A production device and concrete technology, applied in auxiliary molding equipment, ceramic molding machines, mechanical equipment, etc., can solve the problems of easy generation of air bubbles, trouble, affecting the strength and quality of concrete components, and achieve the effect of rapid size and size adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

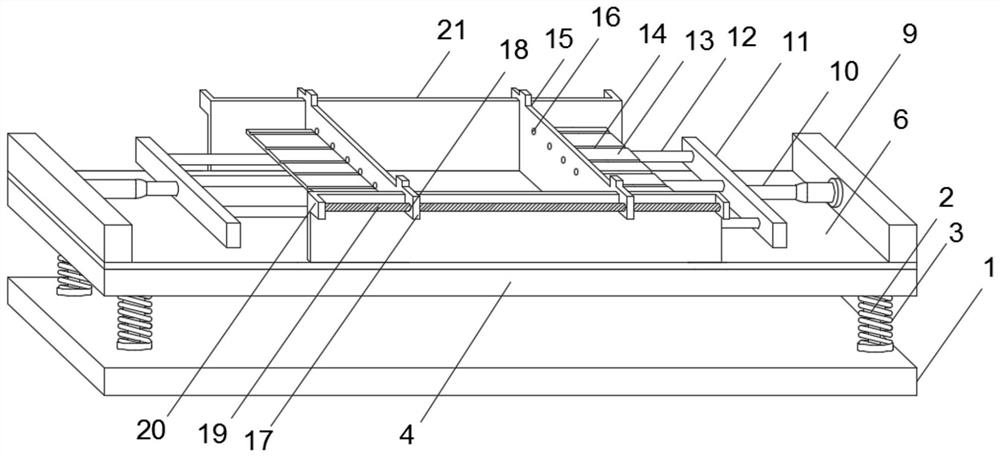

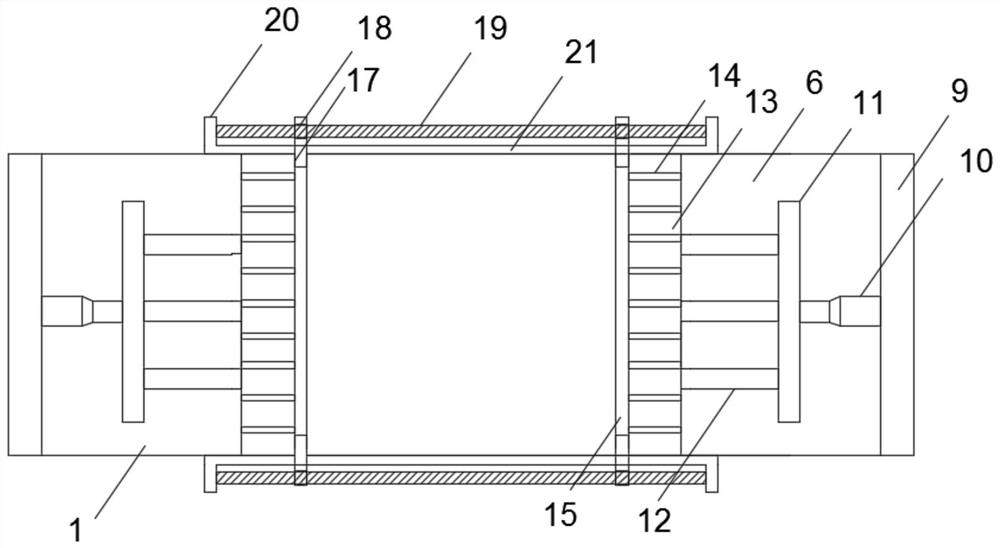

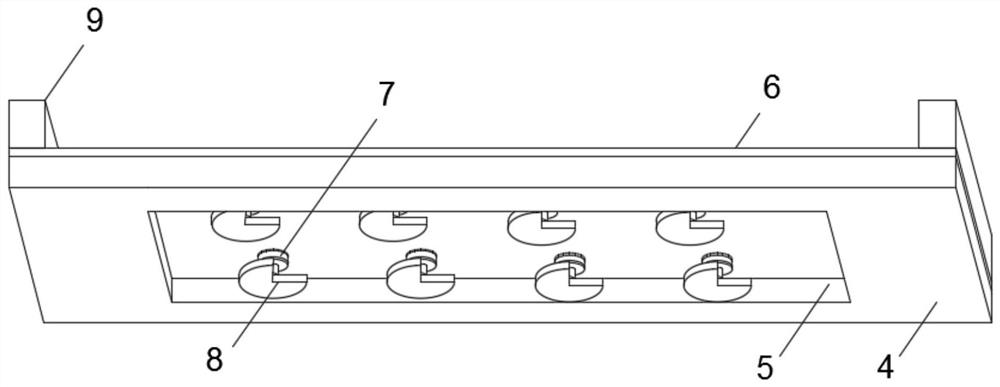

[0039] Refer to attached Figure 1-Figure 7 , a device and a production method for producing concrete components in this embodiment, comprising a production device body one 1, a load-bearing platform 4, a forming bottom plate 6, a forming side plate 21, an adjusting plate 15, a steel bar load-bearing plate 13 and a production device body two 32 The outer surface of the top of the load-bearing platform 4 is provided with a square groove 5, the top of the load-bearing platform 4 is provided with a forming base plate 6, the bottom of the forming base plate 6 is installed with a servo motor 7, the output end of the servo motor 7 is fixedly connected to the eccentric wheel 8, and the top of the forming base plate 6 is installed with a side Plate 9, one side of side plate 9 is fixedly connected with hydraulic cylinder 10, and the output end of hydraulic cylinder 10 is equipped with moving plate 11, and one side of moving plate 11 is fixedly connected with moving rod 12, and one end o...

Embodiment 2

[0049] Refer to attached Figure 8 , a device and production method for producing concrete components in this embodiment, including a production device body 2 32, a reduction motor 29, an internally threaded rod 30 and an externally threaded rod 31, specifically, the production device body 2 32 includes a side plate 9, A reduction motor 29 is installed on one side of the side plate 9, the output end of the reduction motor 29 is fixedly connected to the internal threaded rod 30, and one end of the internal threaded rod 30 is sleeved with an external threaded rod 31, and the external threaded rod 31 is fixedly connected to the adjustment plate 15, and the reduction motor is activated by starting the reduction motor. 29 drives the internally threaded rod 30, drives the externally threaded rod 31 to extend outward, and drives the adjusting plate 15 to slide, so as to quickly adjust the size of the concrete member.

[0050] The use process of the present invention is as follows: wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com