Embroidery process imitating device of computerized flat knitting machine

A computerized flat knitting and process technology, applied in textiles and papermaking, weft knitting, knitting and other directions, can solve the problems of easy adhesion of fluff and yarn flocs, affecting the sliding of the machine head, and troublesome cleaning, so as to improve the quality of textiles and reduce The effect of tangle and broken ends, reducing the number of downtimes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

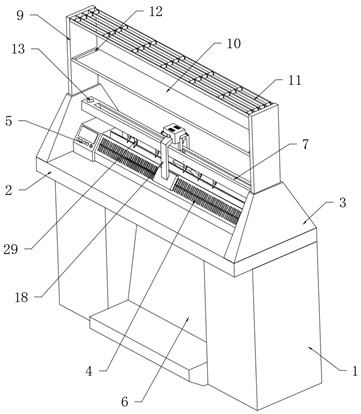

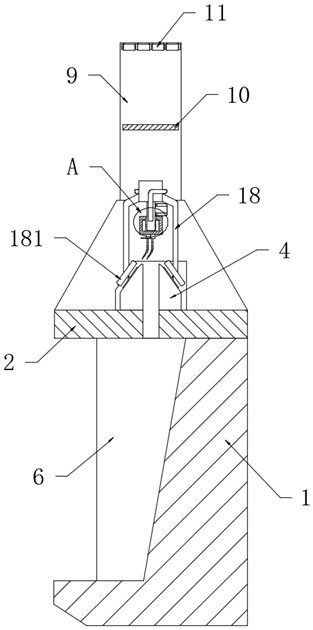

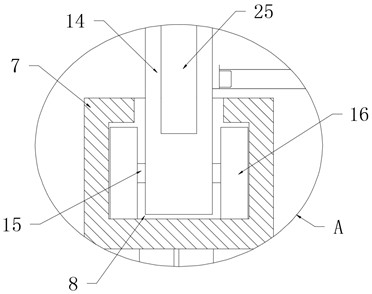

[0024] refer to figure 1 , a computerized flat knitting machine imitating the embroidery process device, comprising a machine base 1, the machine base 1 is fixedly connected with an operating table 2, both ends of the operating table 2 are fixedly connected with a frame 3, and the upper table of the operating table 2 is located on two A textile mechanism 4 is installed between the brackets of the frame 3, a controller 5 is installed at a position close to the frame 3 on one side of the console 2, and a slide bar 7 is fixedly connected to the upper ends of the two frame 3, and the slide bar 7 There is a machine head control device on the top, and the upper end surfaces of the two frames 3 are fixedly connected with a support plate 9, and the middle positions of the two support plates 9 are jointly fixedly connected with a horizontal yarn swing plate 10 for placing yarn required for weaving. Yarn bobbins, the upper ends of the two support plates 9 are jointly provided with a wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com