Mosquito-repelling simulation plant wall and manufacturing method thereof

A technology for simulating plants and plant walls, applied in the field of artificial plant walls, can solve the problems of unfavorable installation site environmental quality, unfavorable cleanliness of artificial plant walls, and many pollutants in artificial plant walls, and achieves improved convenience, easy replacement and cleaning, The effect of maintaining cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

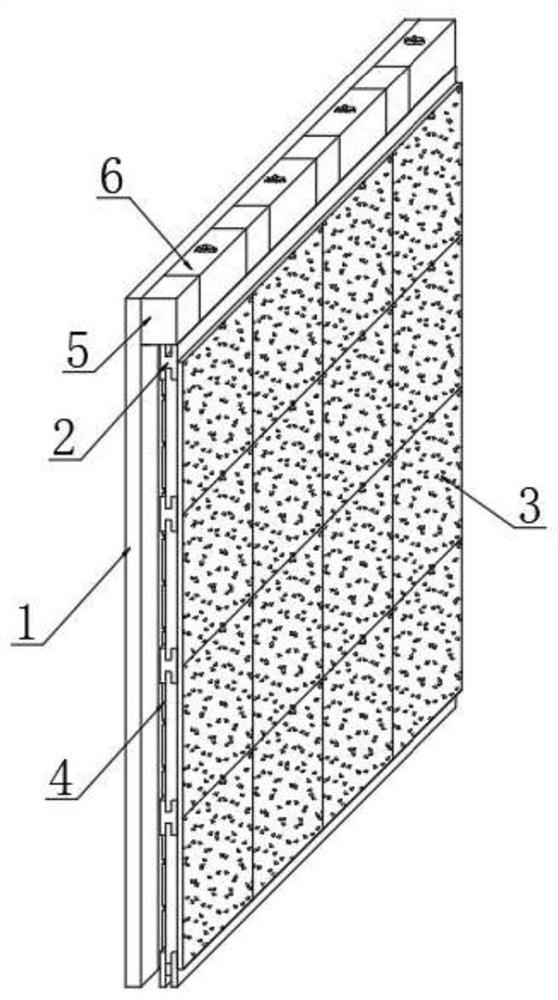

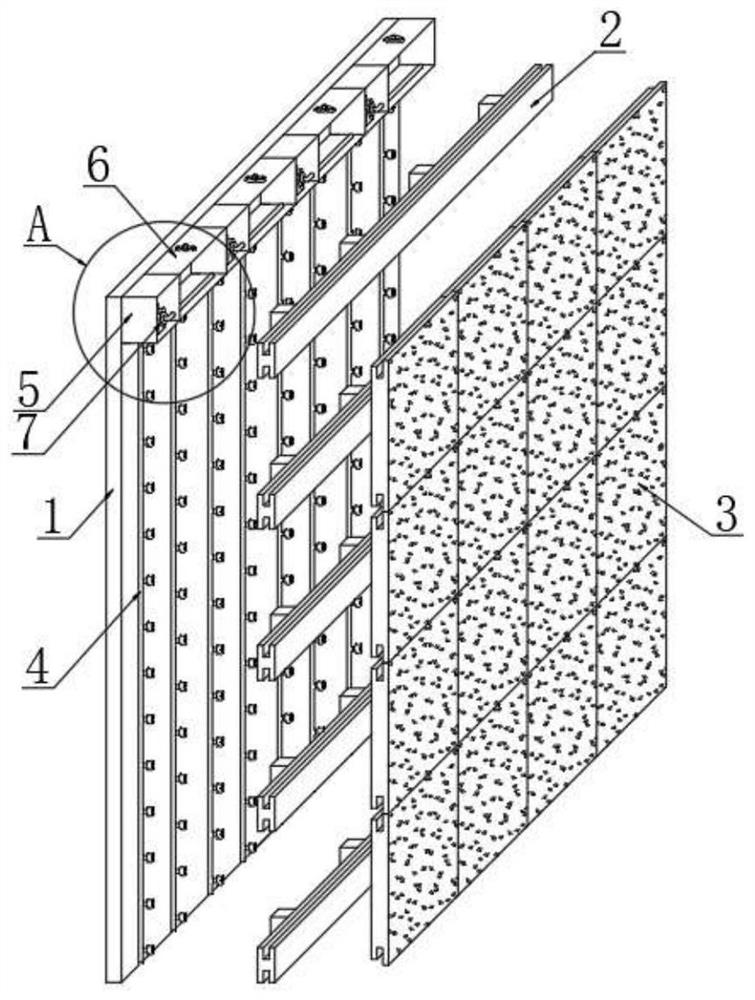

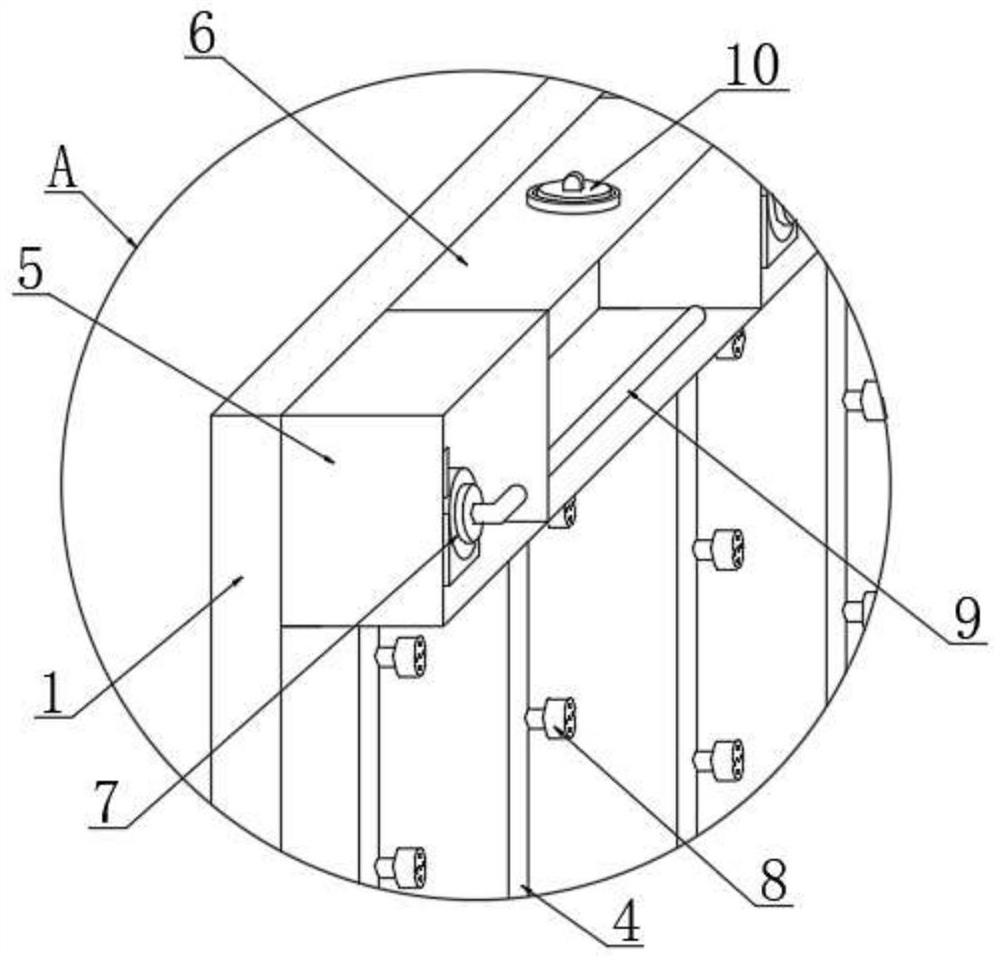

[0032] see Figure 1~5 , in an embodiment of the present invention, a mosquito repelling simulation plant wall, comprising a plant wall installation board 1, one side of the plant wall installation board 1 is fixed with a mounting slat 2, and one side of the installation slat 2 is snapped and installed with a The plant wall simulates plant bricks 3, four sets of pump boxes 5 and liquid tanks 6 are installed on one side of the plant wall installation plate 1, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap