Plastic-steel heat-insulating fireproof window and its production process

A fire-resistant window and plastic steel technology, applied in the field of fire-resistant windows, can solve the problems of deformation of sealing strips and sealing blocks, reduce the heat insulation performance of doors and windows, etc., and achieve the effect of improving stability and strengthening heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following is attached Figure 1-7 The application is described in further detail.

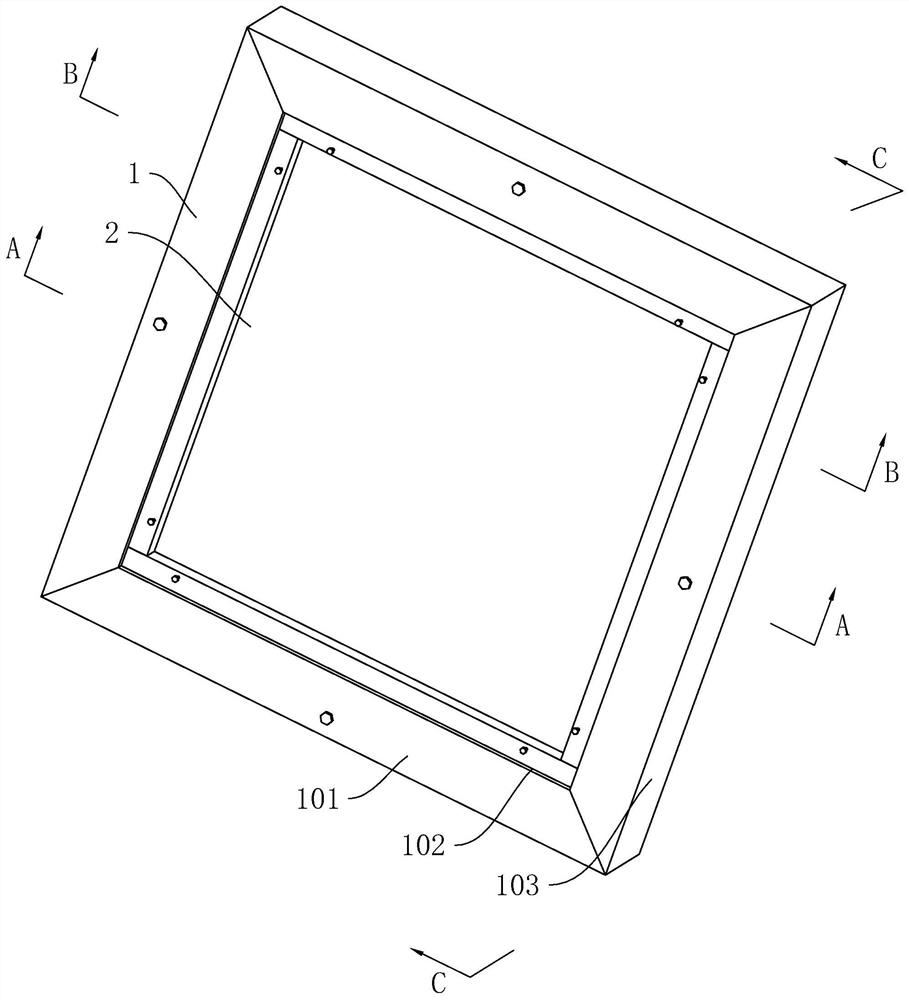

[0051] The embodiment of the present application discloses a plastic-steel heat-insulating fireproof window. refer to figure 1 , The plastic-steel heat-insulating fireproof window includes a window frame 1, and a fireproof glass 2 is installed in the window frame 1.

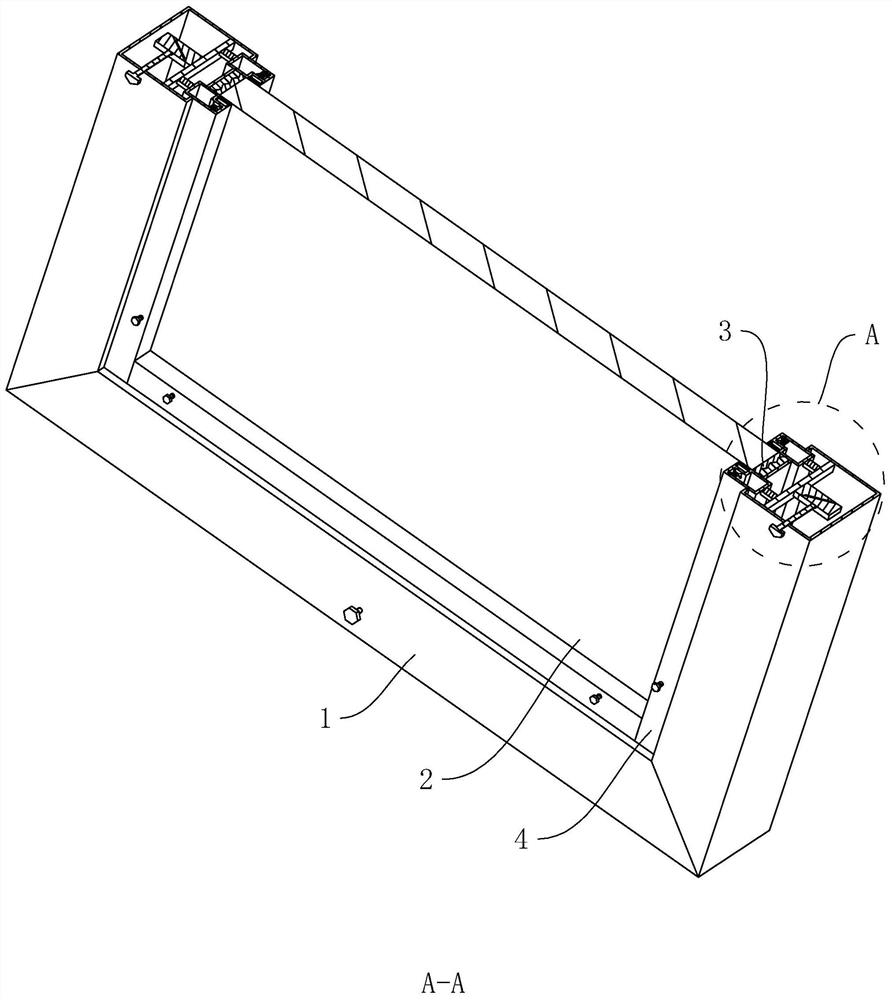

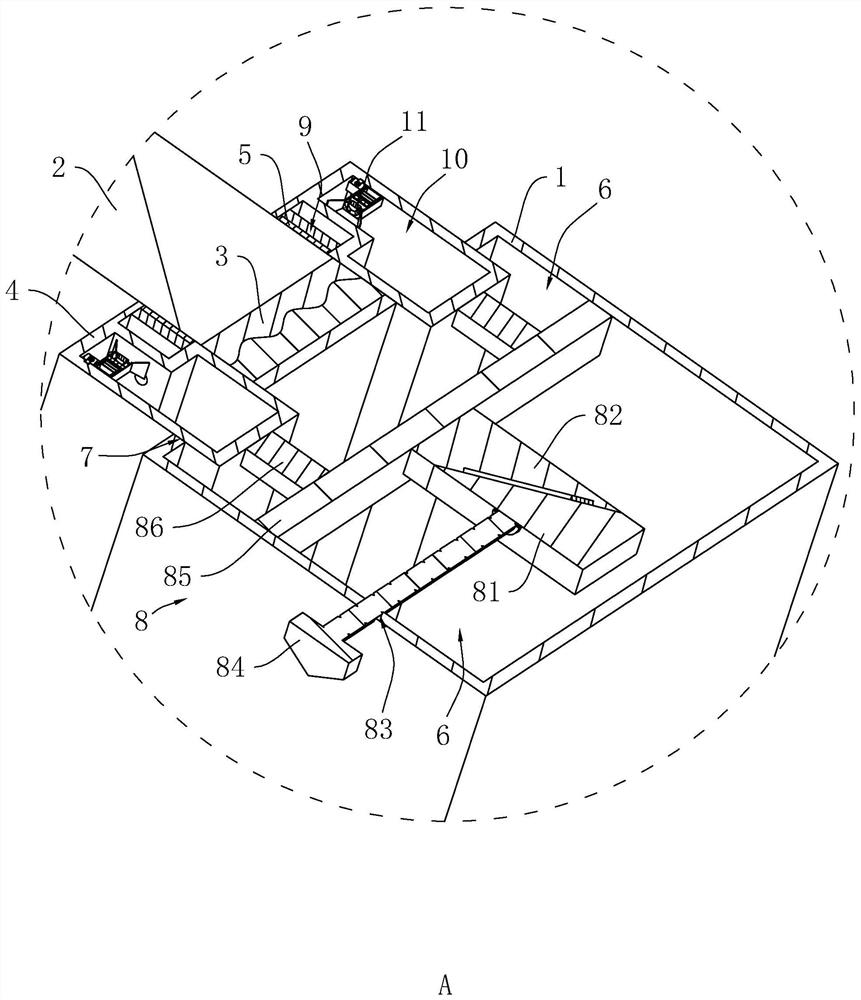

[0052] refer to figure 2 , the inner frame wall of the window frame 1 and the side wall of the fireproof glass 2 are glued with a rubber corrugated plate 3, and the fireproof glass 2 can be pre-fixed in the window frame 1 by matching the two rubber corrugated plates 3 with concave and convex. Furthermore, the sealing between the fireproof glass 2 and the side wall of the window frame 1 is realized, so that the fireproof window has a good heat insulation effect.

[0053] refer to figure 2 and image 3 , the inside of the window frame 1 is provided with four mutually independent cavities 6, each cavity 6 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com