Marine drilling riser connecting device, assembling method and marine riser structure

A technology for marine drilling and connecting devices, which is applied to drill pipes, drilling equipment, drill pipes, etc., can solve problems such as the contact surface of the joint and the riser not fitting, the leakage accident of the riser, and the deformation of the riser. Riser torque, promoting quick loading and unloading, good effect of axial limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

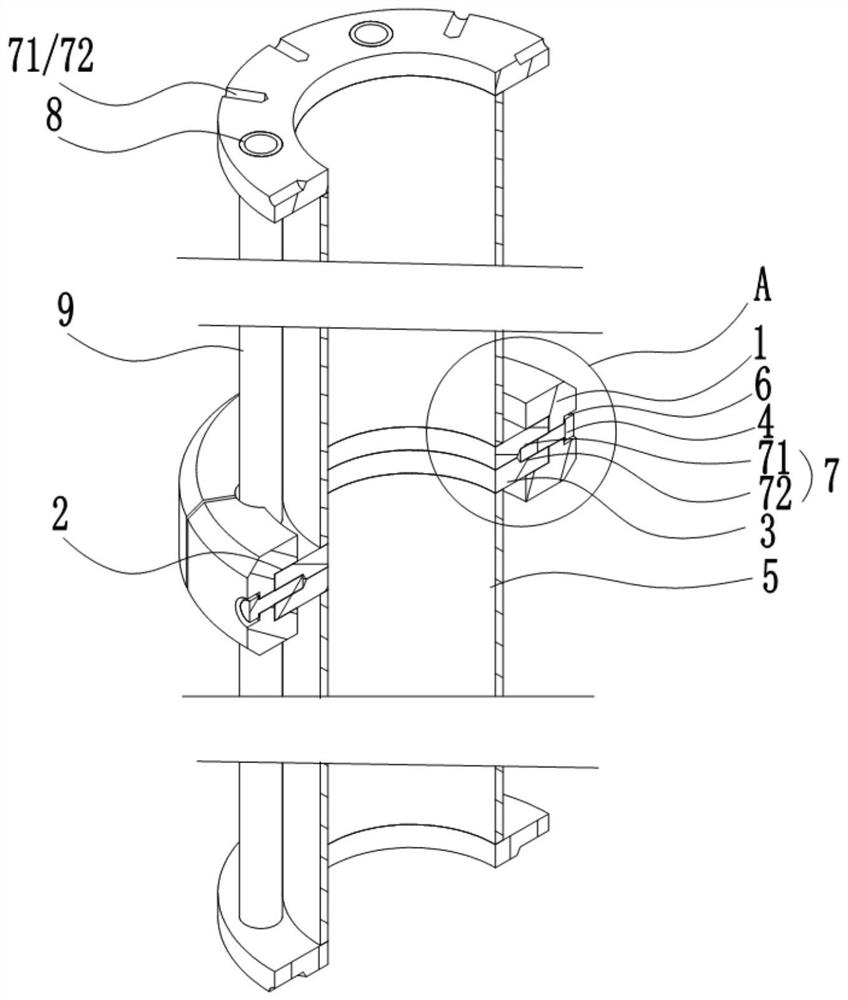

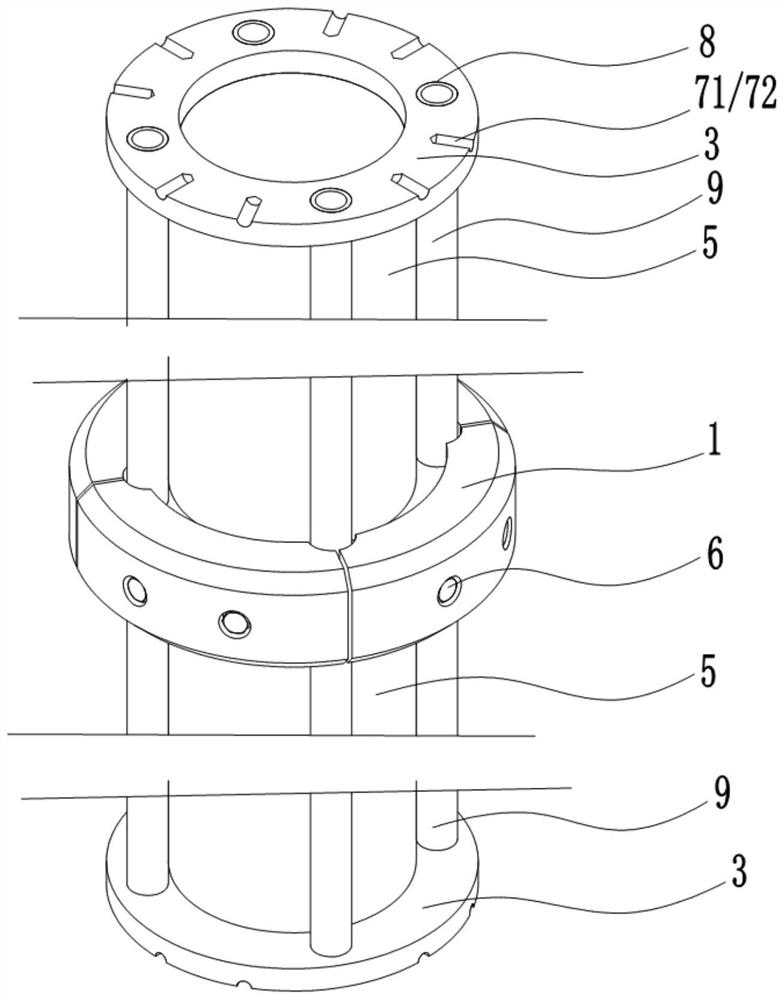

[0036] A connection device for an ocean drilling riser, as shown in Figure 1 to Figure 7 As shown, it includes at least two connection blocks 1 arranged at the flange connection of the riser, the connection blocks 1 are combined and assembled on the outside of the flange connection of the riser, and the inside of the connection block 1 is also provided with a useful The connecting block 1 is assembled on the flange plate 3 through the assembly groove 2 and then fixedly assembled on the flange plate 3 by bolts 4 .

[0037] In this embodiment, the split structure design of the connecting block 1 effectively promotes the efficiency of quick disassembly and assembly of the flange connection of the riser, and effectively improves the efficiency of assembly and disassembly of the riser 5 . At the same time, with the help of the design of the assembly groove 2, the assembly positioning of the flange plate 3 is effectively promoted. Through the matching of the assembly groove 2 and t...

Embodiment 2

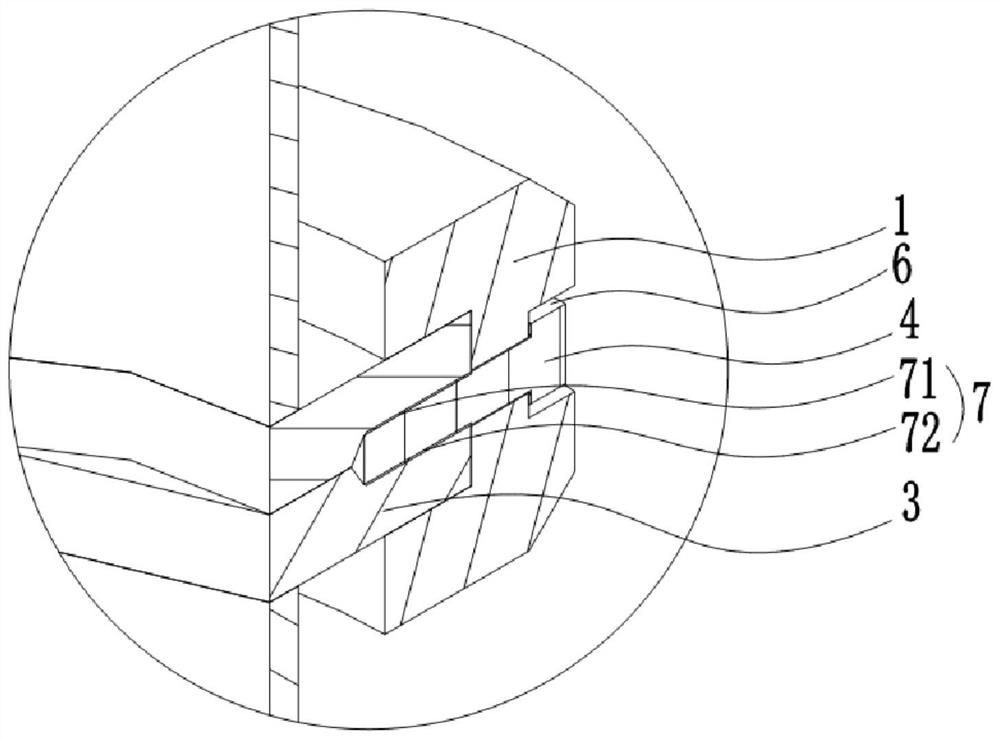

[0043]The design different from Example 1 is the design of assembly holes and internal thread holes. As a different design scheme, specifically, the connecting block 1 is provided with two sets of assembly holes 6, which are located on the upper and lower sides of the flange plate 3. Internally threaded holes 7 corresponding to the assembly holes 6 are respectively provided on the wall, and the connecting block 1 is fixedly assembled through cooperation between the bolts 4 and the assembly holes 6 and the internally threaded holes 7 .

[0044] Specifically, the internally threaded hole 7 is radially designed along the flange 3 . In the specific description of Embodiment 1 and Embodiment 2, the radial direction is a direction perpendicular to the centerline of the flange (or, perpendicular to the centerline of the riser 5).

Embodiment 3

[0046] A marine drilling riser structure, as shown in Figure 1-7, includes a plurality of connected riser pipes 5, flanges 3 are provided at both ends of the riser pipes 5, and the flange plates of the riser pipes 5 A connection device for a marine drilling riser described in Example 1 or Example 2 is provided at the connection.

[0047] As a further design, in order to better ensure the stability of the riser and its own strength, in one specific embodiment, the flange 3 is evenly distributed with through holes 8, through which the through holes 8 An auxiliary pipe body 9 is assembled. After passing this design, the auxiliary pipe body 9 is arranged parallel to the riser 5 .

[0048] As a more optimized design, specifically, a buoyancy device 10 is provided on the outside of the riser 5, and there is a gap between both ends of the buoyancy device 10 and the connecting block 1 to facilitate the placement of auxiliary tools. In the assembly of the entire riser structure, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com