Machine tool spindle oil cooling area sealing performance detection device

It is a technology of sealing detection and machine tool spindle. It is used in the use of liquid/vacuum for liquid tightness measurement, and by measuring the acceleration and deceleration rates of fluids. It can solve air leakage and oil leakage, affect the functionality of machine tools, and affect product brands problem, to achieve the effect of easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

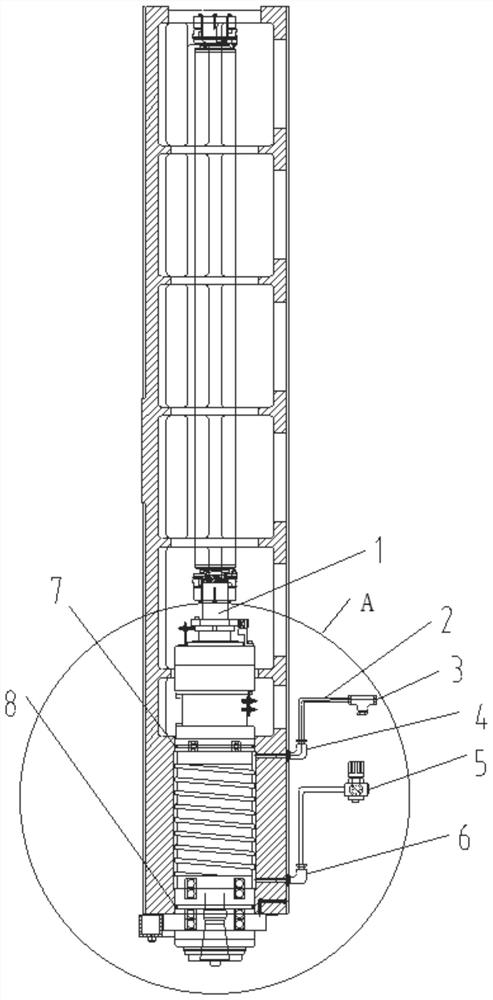

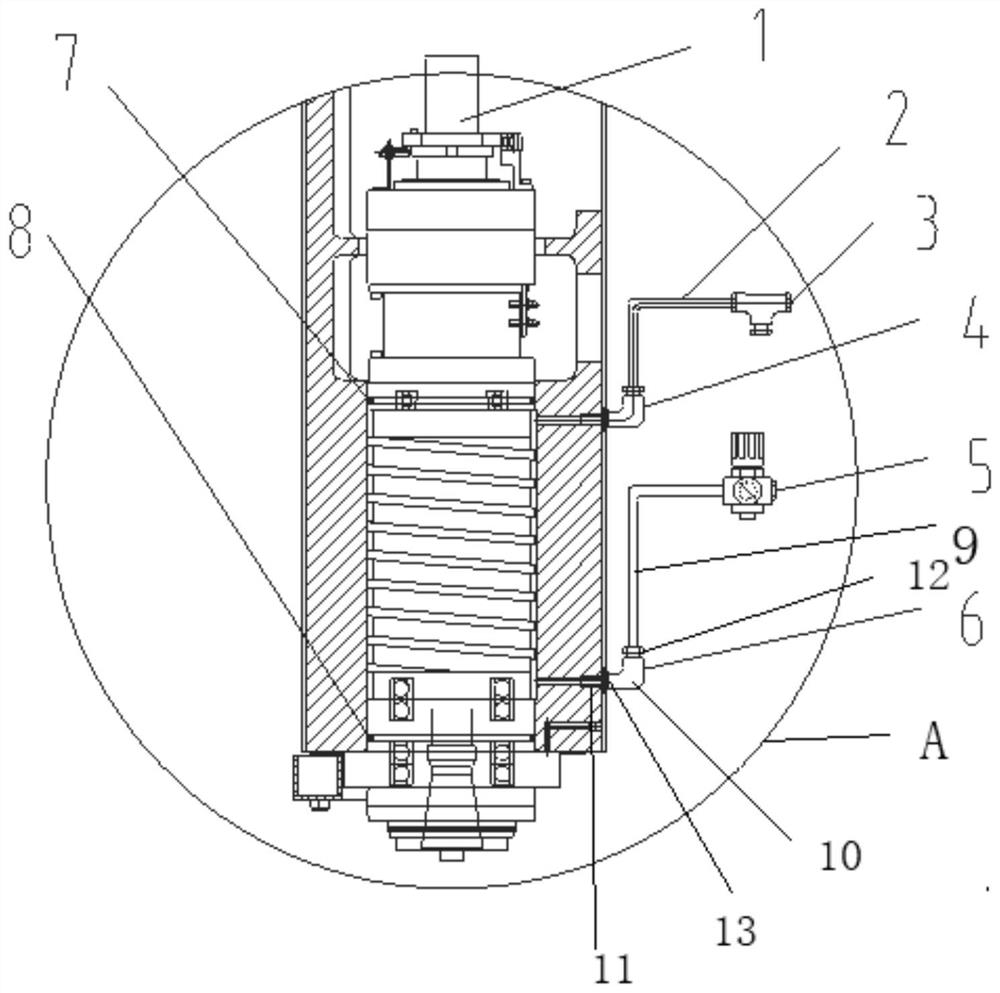

[0024] Examples such as Figure 1 to Figure 7 The airtightness detection device for the oil-cooled area of the main shaft 1 of a machine tool as shown includes a first joint 4 for connecting with the cooling oil outlet below the sealing ring 7 on the oil-cooled area of the main shaft 1, and a first joint 4 for connecting with the oil-cooled area of the main shaft 1. The second joint 6 connected to the cooling oil inlet above the lower sealing ring 8 in the area; the other end of the first joint 4 is connected with the first air pipe 2, and the other end of the first air pipe 2 is connected with the check valve 3; the second joint 6 The other end is connected with a second air pipe 9, and the other end of the second air pipe 9 is connected with a pressure valve 5; the other end of the check valve 3 is connected with an air source.

[0025] The first joint 4 and the second joint 6 are right-angled joints, including a right-angled part 10, an external threaded part 11 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com