Fly-cutting trajectory planning method, fly-cutting control method and fly-cutting system

A trajectory planning and fly-cutting technology, which is applied in the field of component processing, can solve the problems of prolonging processing time and achieve the effects of saving processing time, reasonable path planning, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The fly-cutting trajectory planning method provided in this embodiment is used to plan the final flying-cutting trajectory according to which the laser cutting head of the machine tool cuts the workpiece.

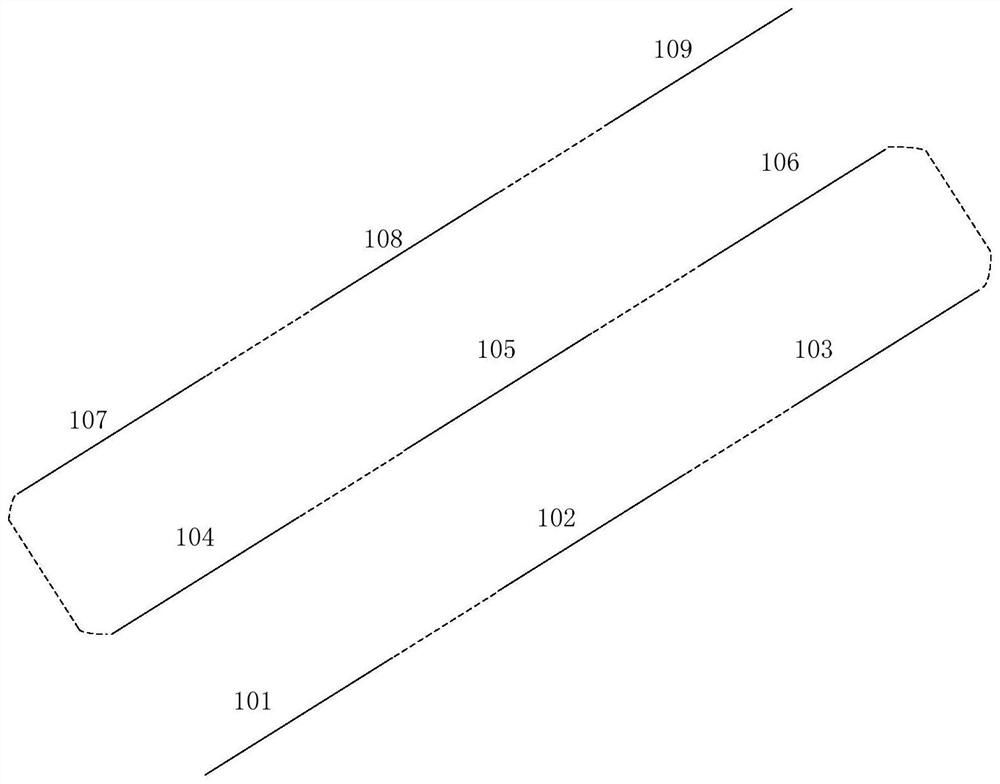

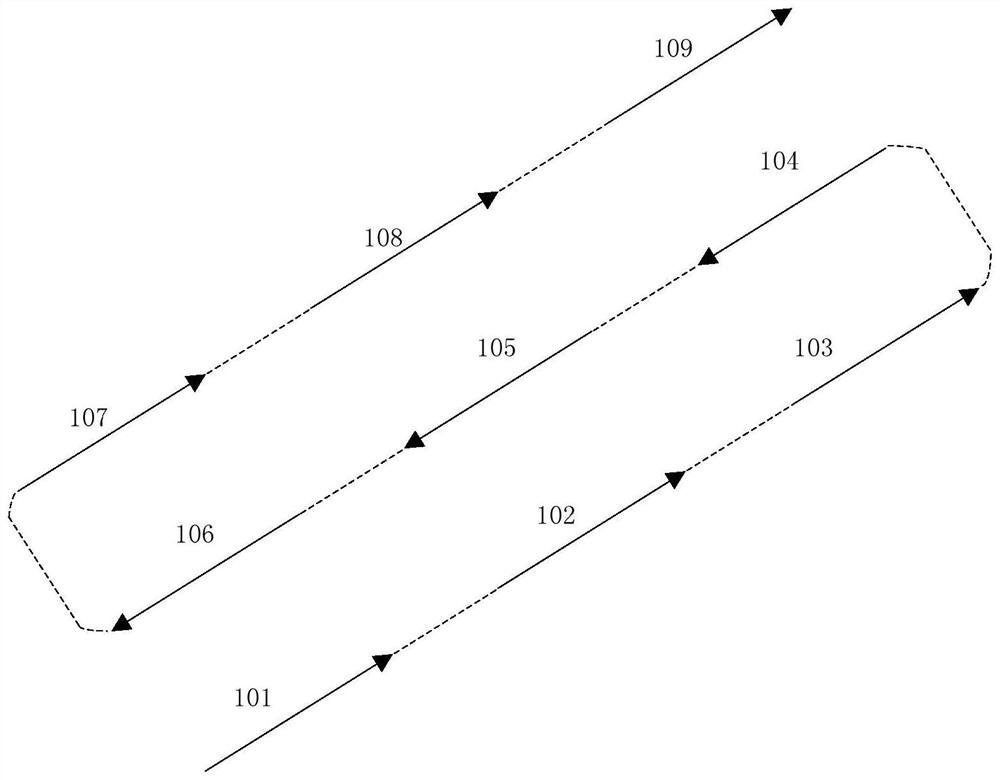

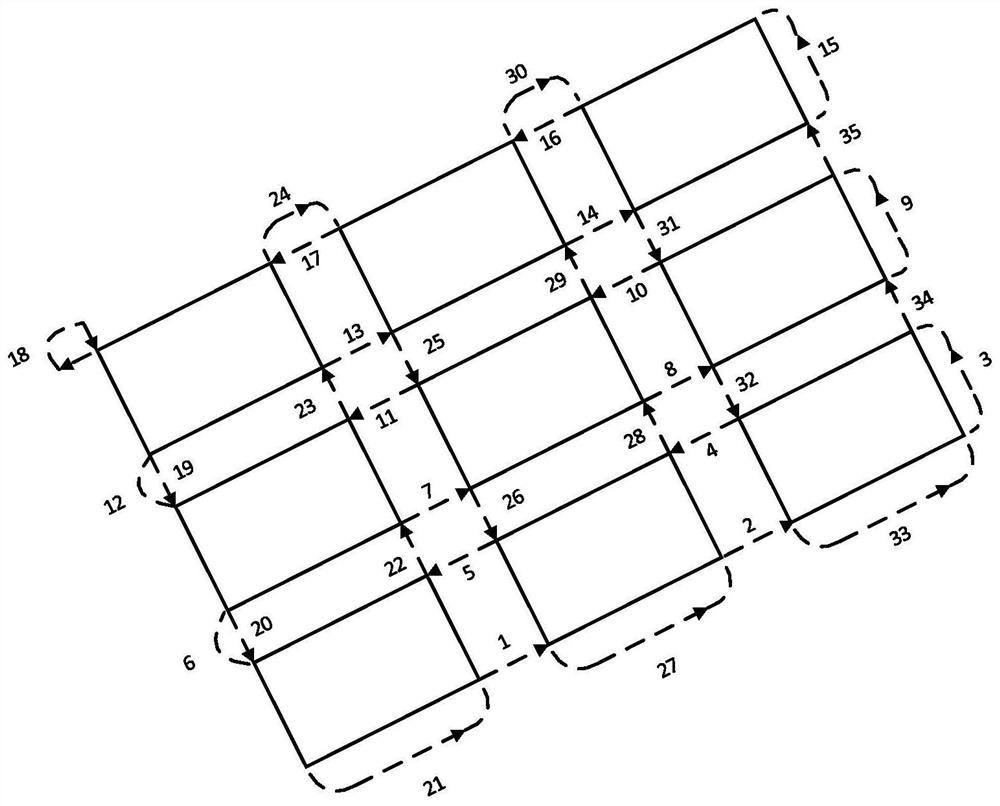

[0070] see Figure 1 to Figure 3 As shown, the fly-cut trajectory planning method provided in this embodiment includes the following steps:

[0071] Step S100, filtering out straight line trajectory segments from the primitives to be processed;

[0072] Step S110, grouping the filtered straight line trajectory segments according to whether they are collinear;

[0073] Step S120, forming at least one straight-line fly-cutting trajectory by sequentially connecting collinear straight-line trajectory segments through connecting straight lines;

[0074] Step S130, when there is one straight-line flying-cutting track, take the straight-line flying-cutting track as the final flying-cutting track; when there are multiple straight-line flying-cutting tracks, connect the adj...

Embodiment 2

[0147] Embodiment 2 provides a flying cutting control method. This embodiment controls the laser cutting head to cut the workpiece along the flying cutting trajectory planning method in Embodiment 1. The technical features of the flying cutting trajectory planning method disclosed in Embodiment 1 are also applicable. In this embodiment, the technical features of the fly-cut trajectory planning method disclosed in Embodiment 1 will not be described repeatedly.

[0148] The flying cutting control method provided in this embodiment controls the laser cutting head to cut the workpiece along the final flying cutting trajectory formed by the flying cutting trajectory planning method. The flying cutting control method includes the following steps:

[0149] When the laser cutting head corresponds to the straight segment track, control the laser cutting head to emit laser light;

[0150] When the laser knife corresponds to the connecting steering line or connecting straight line, contr...

Embodiment 3

[0153] The fly-cutting system provided in this embodiment includes a machine tool with a laser cutting head, a trajectory generating device and a control system.

[0154] The control system is electrically connected with the trajectory generating device and the machine tool respectively; the trajectory generating device can generate the final flying cutting trajectory according to the flying cutting trajectory planning method provided in the first embodiment; the control system can control the work of the machine tool according to the flying cutting control method provided in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com