Miniature electronic component welding device and a maintenance method thereof

A technology for electronic components and welding devices, which is applied in the direction of assembling printed circuits with electrical components, circuit devices, printed circuits connected with non-printed electrical components, etc., to achieve the effects of improving welding quality, avoiding short circuits, and improving electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

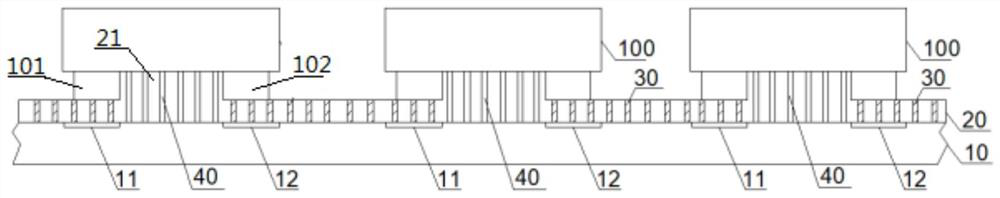

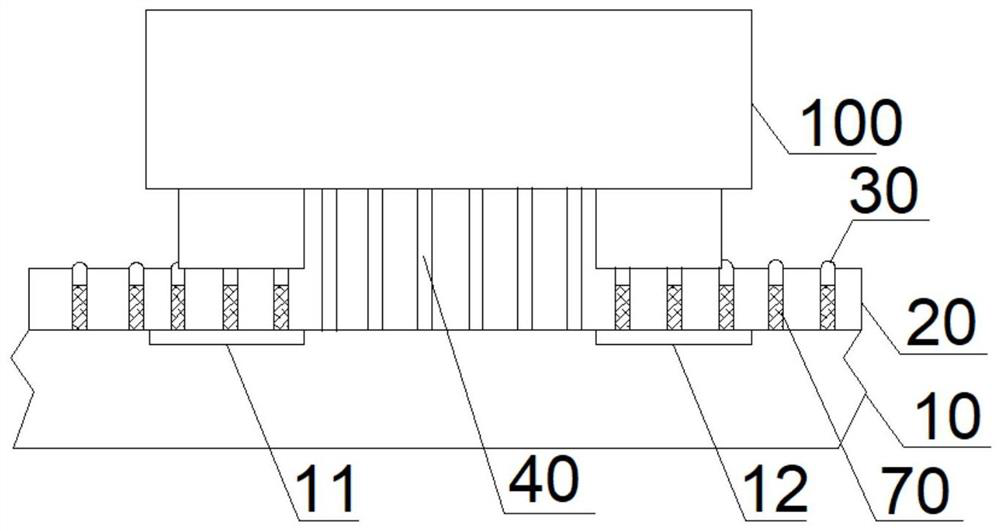

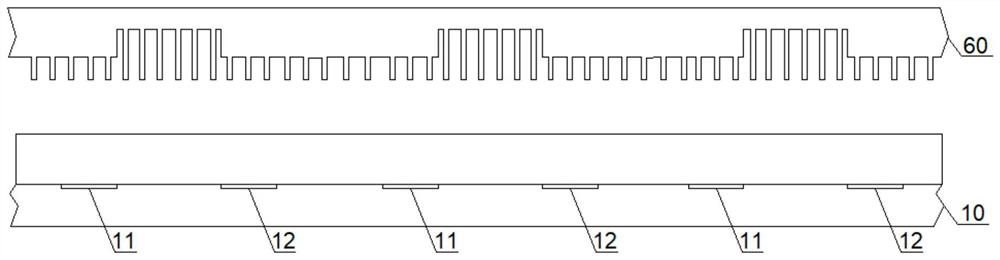

[0046] Such as figure 1 As shown, a kind of miniature electronic component soldering device of the present embodiment comprises a circuit backboard 10 and an intermediate communication structure; on the front surface of the circuit backboard 10, there are many groups of electrode contact pad groups arranged in an array; the intermediate communication structure is arranged on On the front surface of the circuit backboard 10 and cover the electrode contact pad group; the intermediate connection structure is used to movably set the microelectronic component 100, under the state that the microelectronic component 100 is movably arranged on the intermediate connection structure and applies a test signal to the circuit backplane 10 , the electrodes of the microelectronic component 100 are in corresponding contact with the electrode contact pads in the electrode contact pad group to conduct electricity.

[0047]It should be noted that the microelectronic components 100 here can be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com