Electronic cigarette pressing and testing all-in-one machine

An all-in-one machine and e-cigarette technology, which is applied to tobacco, measuring devices, instruments, etc., can solve the problems of inability to test the power of e-cigarettes, and cannot guarantee the quality of e-cigarette production, so as to improve the actual use effect and ensure the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

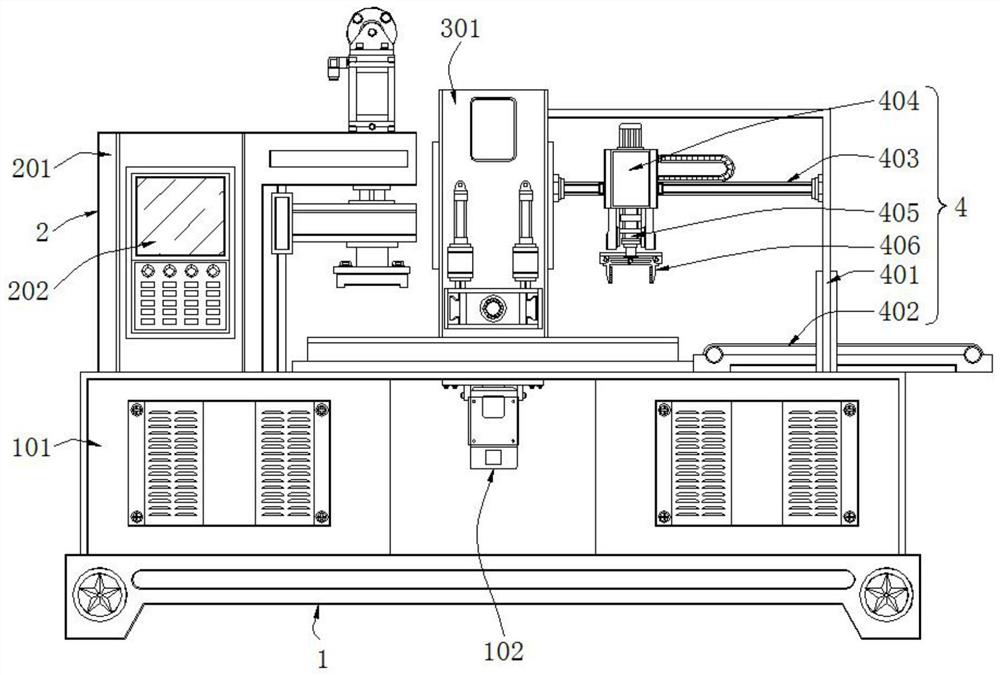

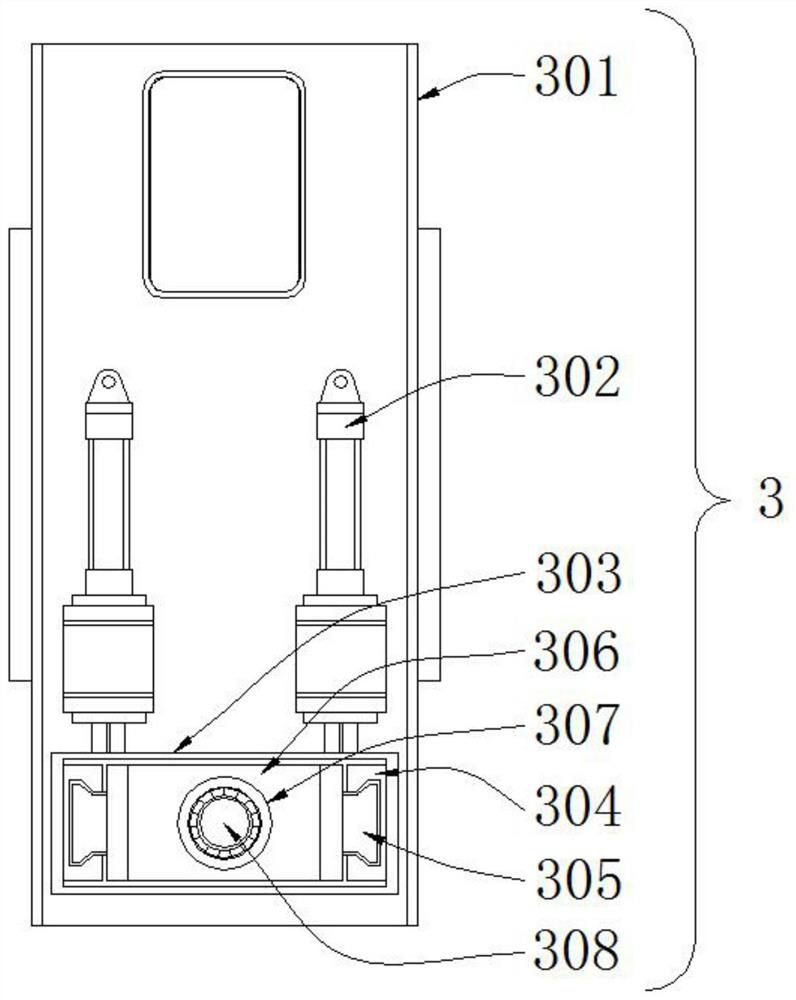

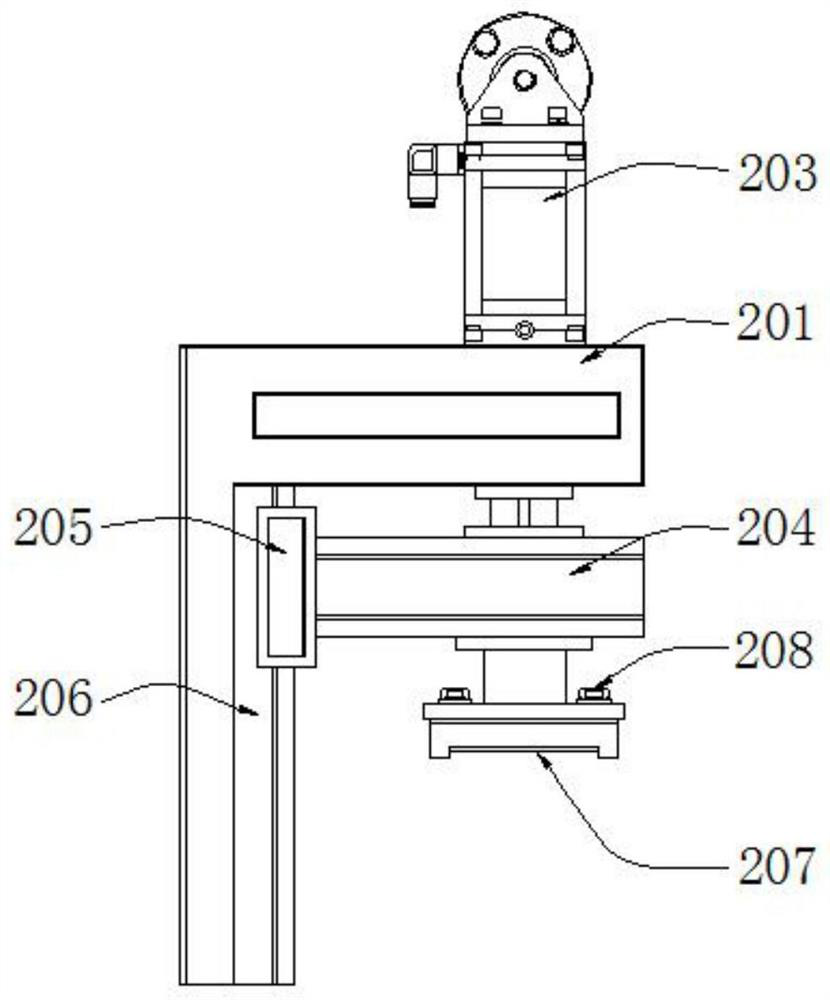

[0027] see Figure 1-5 , an electronic cigarette pressing and testing all-in-one machine, comprising a main body 1 and a testing component 3, the pressing component 2 is arranged on the left side of the upper end of the main body 1, and the testing component 3 is arranged in the middle of the upper end and rear end of the main body 1, and The test assembly 3 includes a connection seat 301, an adjustment cylinder 302, a fixed frame 303, a limit slide rail 304, a limit slide block 305, a placement carrier plate 306, a test plug connection groove 307 and a test plug 308, and the two sides of the front end of the connection seat 301 An adjustment cylinder 302 is provided, and the lower end of the adjustment cylinder 302 is connected with a fixed frame 303, and the inner two sides of the fixed frame 303 are provided with limit slide rails 304, and the outside of the limit slide rail 304 is connected with a limit slide block 305, the limit slide The other side of the block 305 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com