Brake pad lining outer arc grinding equipment and method thereof

A technology for brake pads and linings, which is applied in the field of outer arc grinding equipment for brake pads and linings, can solve the problems of eye damage, small application range, dust and particle splashing, etc., and achieves the effect of being convenient to use and improving the degree of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

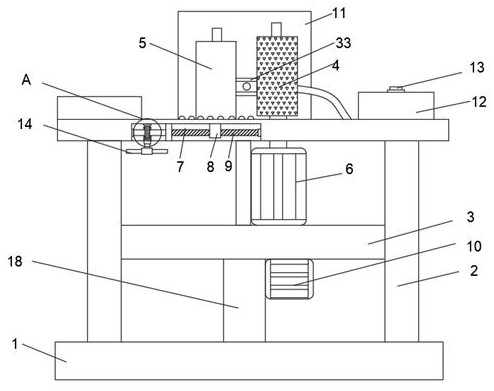

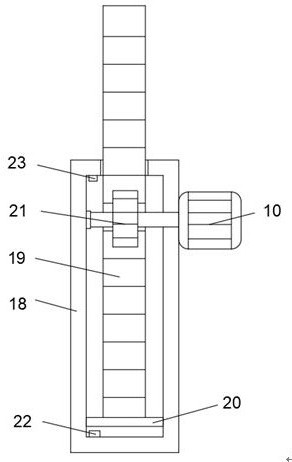

[0033] Such as Figure 1-4 As shown, the embodiment of the present invention provides a brake pad lining outer arc grinding equipment, including a workbench 2, a grinding wheel roller 4 located on the surface of the workbench 2, a driven roller 5 and a dust suction device 33, the grinding wheel roller 4 The bottom is connected with a first motor 6, a connecting plate 3 is arranged between the supporting legs of the workbench 2, a groove 7 is opened on the lower surface of the table of the workbench 2, and an adjustment mechanism is arranged inside the groove 7;

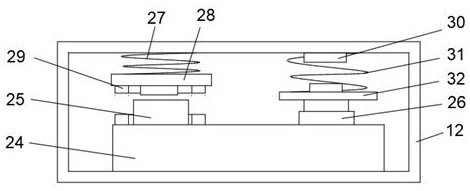

[0034] The upper surface of the workbench 2 is provided with a control box 12, the surface of the control box 12 is provided with a power button 13, and the inside of the control box 12 is provided with a motor forward and reverse controller 24, and the motor forward and reverse controller 24 includes a motor forward and reverse controller on the surface. Turn button 25 and motor reverse button 26, motor forward butto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com