Intelligent polishing equipment for nano ceramic

A nano-ceramic and intelligent technology, applied in the direction of grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of incomplete grinding and polishing, easy to miss, etc., and meet the needs of improving surface accuracy and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

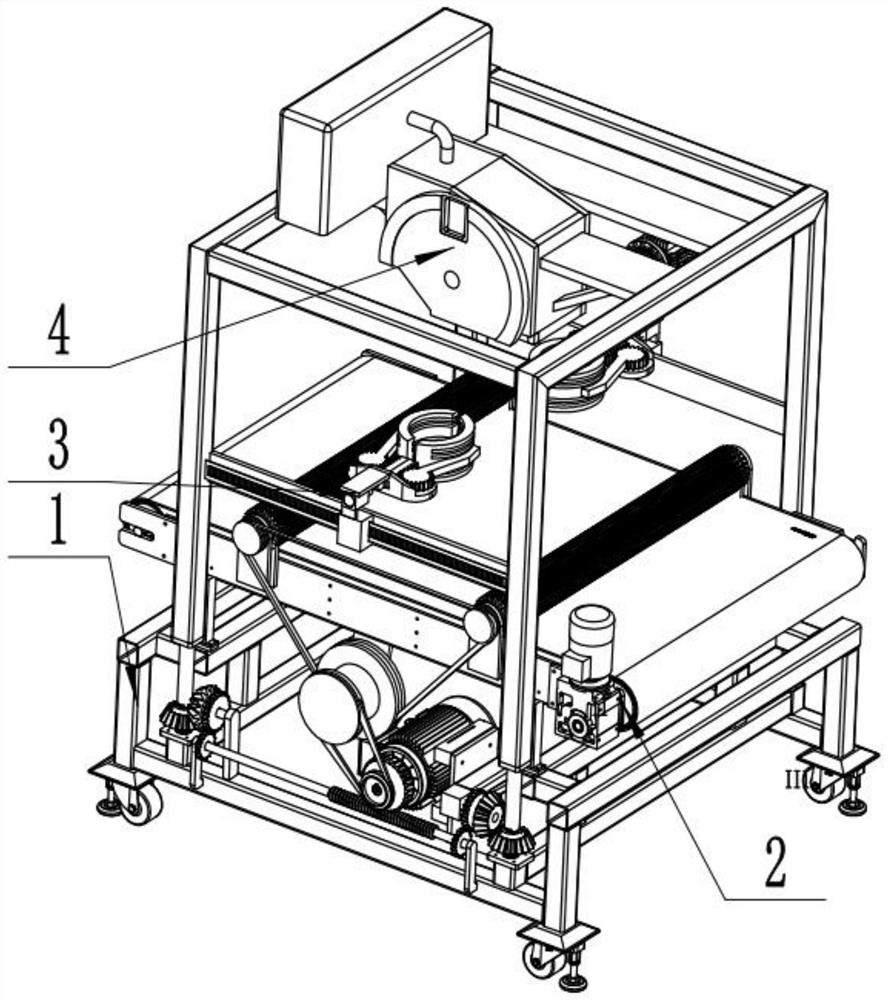

[0021] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The shown intelligent polishing equipment for nano ceramics includes a lifting mechanism 1 , a sanding mechanism 2 , a clamping mechanism 3 and a polishing mechanism 4 .

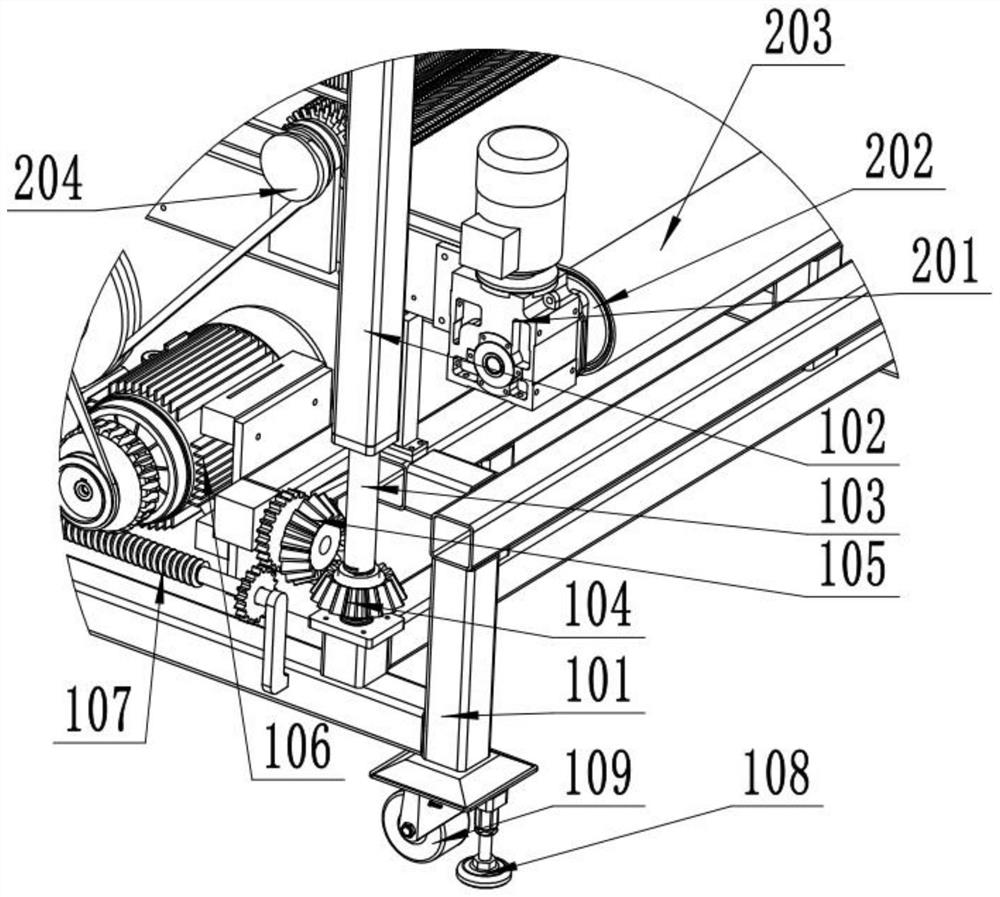

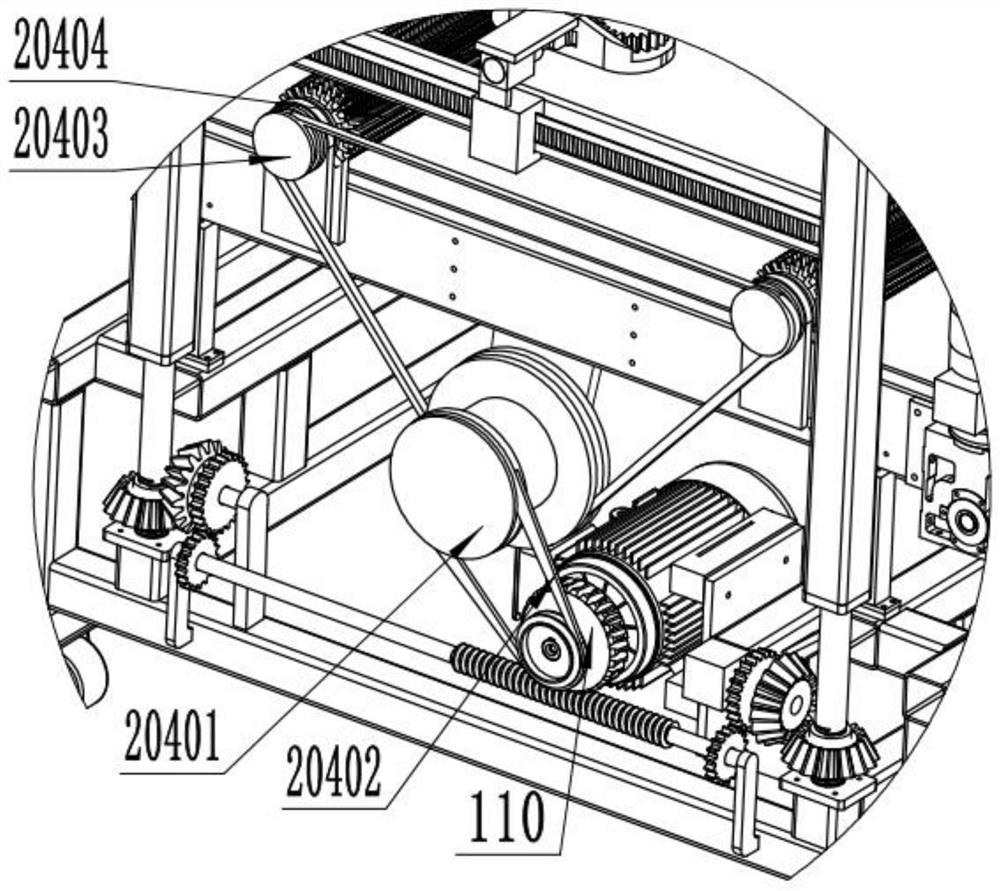

[0022] Such as figure 2 The lifting mechanism 1 shown, the lifting frame 102 and the leading screw 103 are rotatably installed, the leading screw 103 is rotatably installed on the lifting gear 104, the lifting gear 104 and the double-sided gear 105 are rotatably installed on the base 101, and the lifting gear 104 and the double-sided gear The bevel gear end of 105 meshes, and the lifting motor 106 is fixedly installed on the base 101. The output shaft of the lifting motor 106 is fixed with a dual-purpose gear 110, and the transmission rod 107 is rotated and installed on the base 101. The worm part of the transmission rod 107 is connected to the dual-purpose gear. The worm gear on the gear 110 meshes, the spur gear on the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com