Pneumatic atomizing nozzle

An atomizing nozzle and air-flow technology, applied in the direction of spraying device, spraying device, etc., can solve the problems of material liquid pollution, difficult filiform splitting, poor fluidity, etc., and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

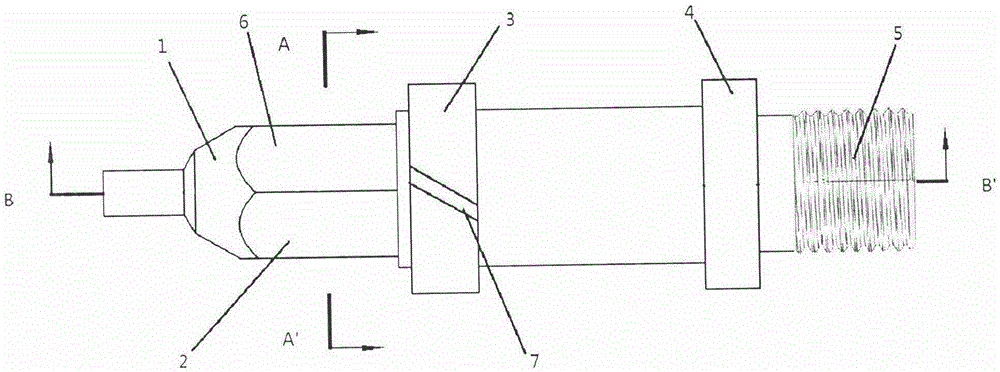

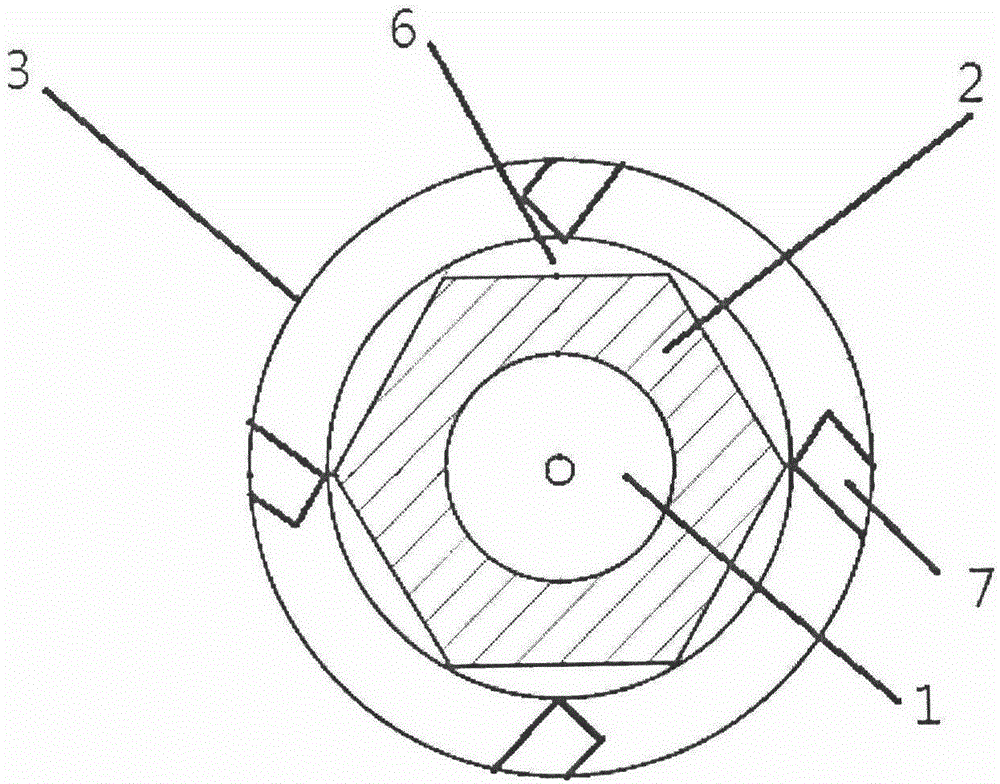

[0026] Such as Figure 1-2 As shown, the front end 1 is an approximately frustum-shaped structure, and the inclined surface is a curved surface with a radius of 10mm; the front part 2 is provided with six symmetrical airways 6, and the radial direction is hexagonal; the middle part 3 is a 8mm first circular ring structure, and four grooves 7 are evenly and symmetrically arranged; the rear part 4 is provided with a second circular ring structure with the same diameter as the middle part 3, and a cylinder with a diameter of 5.9 mm is between the middle part 3 and the rear part 4 shaped structure; the tail part 5 is provided with bolts, and the thread gap is 2-4 wires.

Embodiment 2

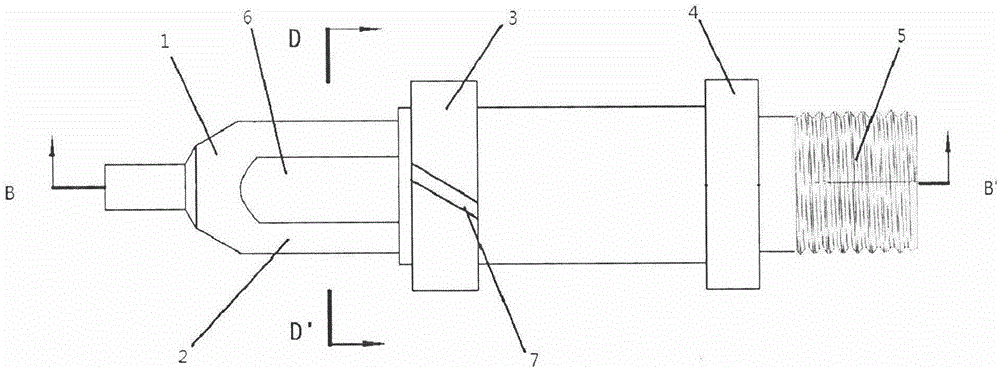

[0028] Such as Figure 3-4 As shown, the front end 1 is an approximately frustum-shaped structure, the inclined surface is a curved surface with an outward protrusion, and the curved surface has a radius of 10mm; the front part 2 is provided with two symmetrical air channels 6, and the radial direction is oblong; The first annular structure is 8mm, and four grooves 7 are evenly and symmetrically arranged; the rear part 4 is provided with a second annular structure with the same diameter as the middle part 3, and a diameter of 5.9mm is between the middle part 3 and the rear part 4. Cylindrical structure; the tail part 5 is provided with bolts, and the thread gap is 2-4 wires.

[0029] It should be pointed out that the shapes and numbers of the air channels 6 and grooves 7 are not unique.

[0030] The function of a kind of airflow atomizing nozzle described in this embodiment is realized as follows:

[0031] The roughness of the front end 1, the front part 2, the middle part 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com