Method for preparing high-whiteness highly-metallic fine and white aluminum paste

A manufacturing method and high-metal technology, applied in pigment slurry, dyeing polymer organic compound treatment, dyeing physical treatment, etc., can solve the problems of wide particle size distribution, poor whiteness and metallic feeling, poor surface smoothness, etc. , to achieve the effect of high cleanliness, high metallic feeling and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

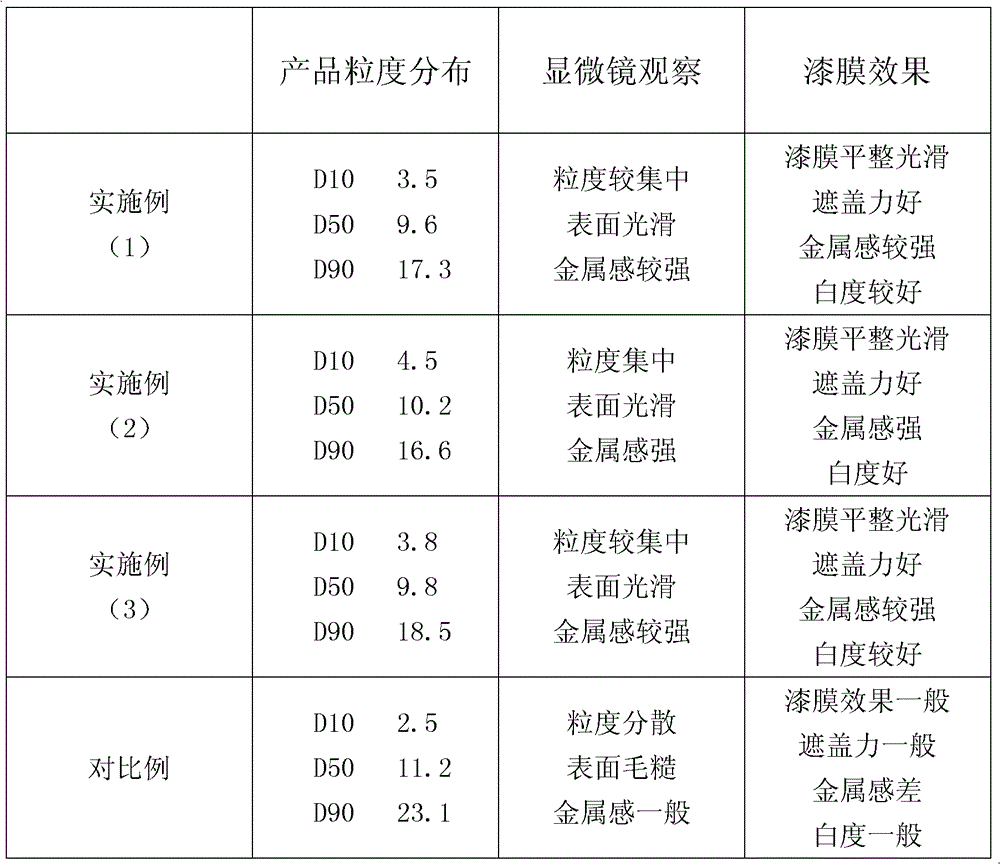

Examples

Embodiment 1

[0020] A manufacturing method of fine white aluminum silver paste with high whiteness and high metallic feeling, including the following steps:

[0021] The first step: once grinding

[0022] Will D 50 19~26μm fine spherical aluminum powder: 30Kg, 200 # Solvent oil: 60Kg, polyethylene wax: 0.4Kg, mixed evenly, placed in a ball mill, choose 800 kg of the first steel ball with two particle sizes of Φ5.0mm and Φ10mm as the ball milling medium, of which Φ5.0mm steel ball, Φ10mm The steel balls account for 40% and 60% of the total steel balls respectively. After 6 hours of grinding, the material is discharged and filtered directly to obtain the first filter cake with a solid content of 75-80%. The filtrate is returned to the ball milling process for recycling;

[0023] Step 2: Secondary fine grinding and polishing

[0024] The first filter cake obtained in the first step: 60Kg and 200 # Solvent oil: 70Kg, polyethylene wax: 0.3Kg, sodium lauryl sulfonate: 0.1Kg, mix evenly, choose 1300 kg o...

Embodiment 2

[0029] A manufacturing method of fine white aluminum silver paste with high whiteness and high metallic feeling, including the following steps:

[0030] The first step: once grinding

[0031] Will D 50 19~26μm fine spherical aluminum powder: 50Kg, D80: 100Kg, polyethylene wax and stearic acid total 0.7Kg (including polyethylene wax: stearic acid = 1:1), mix well, place in a ball mill, select the diameter 1,400 kilograms of the first steel ball with seven particle sizes of Φ3.0mm, Φ5.0mm, Φ7.0mm, Φ9.0mm, Φ11.0mm, Φ13.0mm, Φ15mm are used as the ball milling medium, among which: Φ3.0mm steel ball, Φ5 .0mm steel balls, Φ7.0mm steel balls, Φ9.0mm steel balls, Φ11.0mm steel balls, Φ13.0mm steel balls, and Φ15mm steel balls account for 10%, 10%, 15%, and 30% of the total steel balls, respectively , 15%, 10%, 10%, after 8 hours of grinding, the material is discharged and filtered directly to obtain the first filter cake with a solid content of 75-80%, and the filtrate is returned to the b...

Embodiment 3

[0038] A manufacturing method of fine white aluminum silver paste with high whiteness and high metallic feeling, including the following steps:

[0039] The first step: once grinding

[0040] Will D 50 Fine spherical aluminum powder of 19~26μm: 40Kg, S150: 60Kg, stearic acid: 0.55Kg, mix evenly, put it in a ball mill, choose four particle sizes: Φ3.0mm, Φ7.0mm, Φ11.0mm, Φ15mm 1300 kg of the first steel ball is used as the ball milling medium. Among them: Φ3.0mm steel ball, Φ7.0mm steel ball, Φ11.0mm steel ball, Φ15mm steel ball account for 15%, 35%, 35%, 15%, the material is discharged after 10 hours of grinding, and directly press-filtered to obtain the first filter cake with a solid content of 75-80%, and the filtrate is returned to the ball milling process for recycling;

[0041] Step 2: Secondary fine grinding and polishing

[0042] The first filter cake obtained in the first step: 70Kg and S150: 85Kg, stearic acid: 0.45Kg, and sodium dodecyl sulfonate 0.2Kg are mixed uniformly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com