An automatic vibrating device for a building angle plate combined mold

A combined mold and vibrating device technology, applied in the field of vibrating, can solve the problems that concrete cannot be vibrated at the same time and affect the processing efficiency of prefabricated components, so as to shorten the vibrating time, reduce the processing cost and improve the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

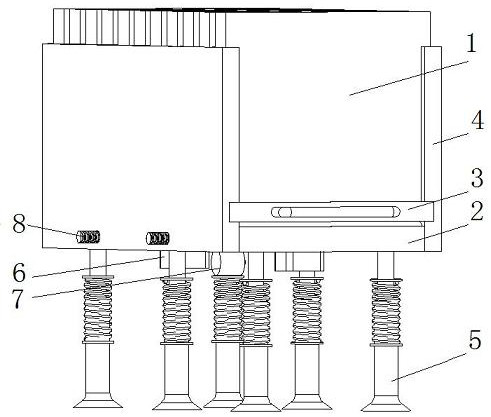

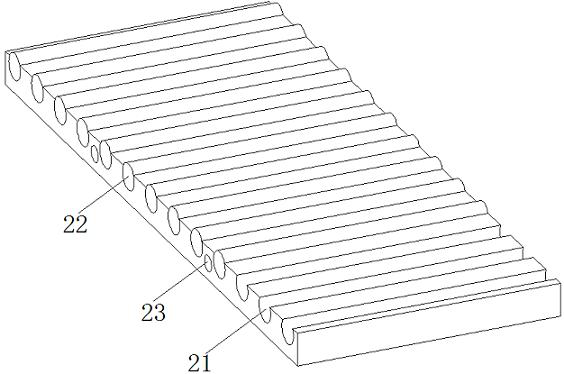

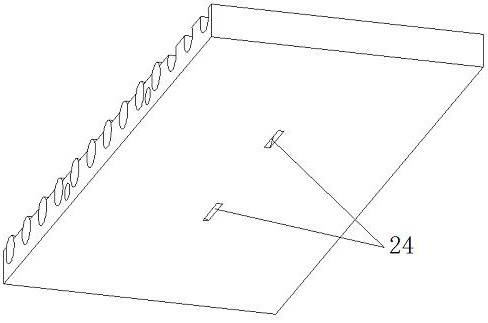

[0025] Example: refer to figure 1Shown: an automatic vibrating device for a combined mould of a building corner plate, comprising a plurality of corner plate moulds 1, the plurality of corner plate moulds 1 are evenly placed in parallel along a horizontal line, a support plate 2 is horizontally arranged below the corner plate mould 1, and the support plate 2 A support plate 3 is arranged horizontally between the corner plate mold 1, the support plate 3 is snap-connected with the corner plate mold 1, the support plate 3 is slidably connected with the support plate 2, and the outer sides of the two long sides of the support plate 2 are vertically provided with fixed Plate 4, the fixed plate 4 is located on both sides of the corner plate mold 1 and connected, the two ends of the lower horizontal side of the support plate 2 are fixedly connected with a vibrator 6, and the middle of the lower horizontal side of the support plate 2 is fixedly connected with a motor 7, The lower hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com